配件详情

麦克福斯约翰迪尔发动机零配件

|

|

|

约翰迪尔 4045 4.5T/H 活塞(米) RE515037 排放 2 & 3

|

型号 |

数量 |

描述 |

|

TMX504 |

1 |

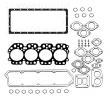

约翰迪尔(John Deere) 强鹿4045D 4.5D发动机试剂盒 (4) |

|

TR114083 |

8 |

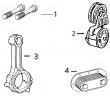

约翰迪尔(John Deere) 强鹿4045D 4.5D发动机连杆螺钉 |

|

TR115299 |

6 |

约翰迪尔(John Deere) 强鹿4045D 4.5D发动机BUSHING, BAL SHAFT |

|

TR119874 |

1 |

约翰迪尔(John Deere) 强鹿4045D 4.5D发动机轮轴衬套 |

|

TR123960 |

4 |

约翰迪尔(John Deere) 强鹿4045D 4.5D发动机连杆衬套 PT 35 mm |

|

TRE31617 |

8 |

约翰迪尔(John Deere) 强鹿4045D 4.5D发动机气门密封 STEM LITER ENG |

|

TRE44574 |

1 |

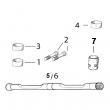

约翰迪尔(John Deere) 强鹿4045D 4.5D发动机前油封 |

|

TRE501455 |

1 |

约翰迪尔(John Deere) 强鹿4045D 4.5D发动机大修包 |

|

TRE505515 |

1 |

约翰迪尔(John Deere) 强鹿4045D 4.5D发动机后油封 |

|

TRE65165 |

4 |

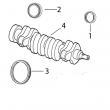

约翰迪尔(John Deere) 强鹿4045D 4.5D发动机主轴瓦(标准) |

|

TRE65168 |

1 |

约翰迪尔(John Deere) 强鹿4045D 4.5D发动机止推瓦(标准) |

|

TRE65908 |

4 |

约翰迪尔(John Deere) 强鹿4045D 4.5D发动机连杆瓦(标准 |

|

TRE65966 |

4 |

约翰迪尔(John Deere) 强鹿4045D 4.5D发动机活塞缸套四配套,包括活塞,活塞环,活塞销,缸套,卡簧,阻水圈 (RE59279) |

|

|

||||||||||||||||||||||||||||

(1)1件组合式密封和穿套; 替换TRE59810,RE538097。

(2)在曲轴加工过程中必须保持正确的轴承轴颈半径,以确保正确操作。

(3)锥形鼻子。

(4)直鼻。

(5)检查应用程序是否正确使用。

(6)线路连接都是线程化的。

(7)线路连接是一个软管倒钩& 一个线程。

(8)线路连接是两个软管倒钩。

(9)机器分体式和断裂式分体式连杆均可用于同一台发动机,但每个连杆必须使用正确的连杆螺栓。

强鹿JOHN DEERE柴油机配件、发动机配件、发电机组:

RE515368、RE62420、RE65414(24V)、RE500227、SE501836、SE501828、SE501823、RE533516、RE525690、RE16809、RE16808、RE509672、RE525523、RE523236、RE525523、RE62424、RE504564、RE160384、RE557343、RE533910、RE532952、RE530107、RE531808、RE507981、RE532627、RE518176、RE532628、RE519774、RE533608、RE522528、RE519774、RE532628、 RE518176、RE507980、RE518503、RE522515、RE504836、RE509031、RE509032