帕金斯柴油发动机3012喷油器的谈细参数与维修保养技术

帕金斯柴油发动机3012喷油器的谈细参数与维修保养技术

Fuel injectors

燃料喷射器

1 Disconnect and remove the high-pressure

pipes

1断开并拆下高压管道

and the spill pipes. For early engines, remove

the

和泄漏管道。对于早期的发动机,删除

relevant rocker box cover, operation 12-4.

Release

相关摇臂箱盖,操作12-4。释放

the connection for the leak-off fuel from the

fuel

燃油从燃油中泄漏的连接

injector and remove it through the wall of the

rocker

喷油器并将其拆下摇臂的壁

box. For new engines, remove the relevant

pedestal

箱。对于新发动机,拆下相关底座

rocker cover, operation 12-1.

摇杆盖,操作12-1。

2

Release the cap screw of the clamp which retains

2松开保持夹持的盖螺钉

the fuel

injector and withdraw the injector. A fuel

喷油器和喷油器的喷射。燃料

injector which is

tight in the cylinder head may be

在气缸盖上的喷油器可能是

released by the use of the

slide hammer, 21825 849

使用滑动锤释放,849 21825

(A1) and the adaptor, 21825 854

(A2).

(A1)和适配器,21825 854(A2)。

Caution: Ensure that the copper fuel

injector sleeve

警告:确保铜燃油喷射套管

is not loosened in the cylinder head when the

s lide

不松开气缸盖时的利得

hammer is used. If this occurs, refer to operation

12-

用锤子。如果发生这种情况,参考操作12—

1 Check that the sleeve of each injector is

clean.

1检查每个喷油器的套是否干净。

2 If relevant, remove the connection for the

leak-off

2如果有相关的话,删除连接泄漏

fuel from eac h fuel injector and fit carefully

each fuel

从每个喷油器的燃油和适合仔细每个燃料

injector into its s leeve, with the threaded

hole for the

喷油器成的堤防,与螺纹孔的

leak-off fuel toward the outer wall of the

rocker box.

向摇杆箱外壁泄漏燃料。

Caution: If a Bosch fuel injec tor is to be fitted

to an

注意:如果一个博世喷油器是安装在一个

early engine, instead of a CAV or an OMAP

fuel

早期的引擎,而不是一个CAV或OMAP燃料

injector previously fitted, a new connection

and a new

注射器先前安装,一个新的连接和一个新的

washer for the leak-off fuel must also be

fitted

泄漏燃油的垫圈也必须安装

(assembly CV 17009/1).

(汇编1 / 17009)。

3 Fit the

assembly of the metal cup and the rubber

3配合金属杯和橡胶的装配

seal against the

head of each connection for the leak-

密封的每个连接的头的泄漏—

off fuel and fit a new

copper washer onto the thread.

燃油,并将一个新的铜垫圈安装到螺纹上。

For early engines,

insert each connection through

对于早期的发动机,插入每个连接通过

the openings in the outer

walls of the rocker boxes

摇杆箱外壁上的开口

and fit the connection into its fuel

injector, finger-tight.

并将其安装到燃油喷射器中,将其拧紧。

4 Fit each injector with its

clamp and put a spherical

4配合每一个喷油器,用它的钳位,并把一个球

washer in its location in

each clamp. Fit the cap

在每个夹具中的定位垫圈。安装盖

screws through the washers and

clamps and tighten

通过垫圈和卡箍并拧紧

them to 60 Nm (42 lbf ft).

他们以60

nm(42磅英尺)。

5 For early engines, when all the cap screws of

the

5为早期发动机,当所有的帽螺丝

clamps are tight, tighten the connections for

leak-off

卡紧,拧紧连接泄漏

fuel to 27 Nm (20 lbf ft).

燃料27牛米(20磅英尺)。

6 Check

that the joint face of each rocker box is

6检查各摇杆箱的接头面是否

clean. Fit a new

joint for each rocker box cover and

清洁。为每个摇杆箱盖安装新接头

align correctly the

bolt holes.

正确对齐螺栓孔。

7 Fit a new ’O’ ring to the groove at the top of

each

7在每一个顶部安装一个新的'氧'环'

fuel injector. Fit carefully each rocker box

cover. Fit

喷油器。小心地安装每一个摇杆箱盖。适合

the 8 bolts, with plain and spring washers,

through the

8个螺栓,用平和弹簧垫圈,通过

bolt holes of each rocker box cover and

tighten them

每个摇杆盖的螺栓孔,并拧紧

to 27 Nm (20 lbf ft). For new engines, fit a

new ’O’

27牛米(20磅英尺)。对于新引擎,适合新的“哦”

ring around the groove which is near the

top of each

环附近的槽,这是附近的顶部

fuel injector and fit the pedestal rocker

cover,

喷油器和安装底座摇臂盖,

operation 12-21.

操作12-21。

8 If other work is to

be completed, fit temporarily a

8如果其他工作要完成,暂时不适合

cover or a plug to each

of the open connections of the

盖或插头各开连接的

fuel injectors.

燃料喷射器。

9

For all engines, if relevant, remove the cover from

9对于所有发动机,如果相关,从

the

outlet connection for leak-off fuel of each fuel

每种燃料的泄漏燃料的出口连接

injector.

Put a new copper washer on each side of the

喷油器。在每边上放一个新的铜垫圈

banjo

connections and fit the pipes between the fuel

班卓琴的连接和配合,燃料管

injectors and

the connection block for leak-off fuel.

喷油器和泄漏燃油的连接块。

Tighten securely

each banjo connection bolt and

拧紧各连接螺栓和班卓琴的安全

each union

nut.

每个工会的坚果。

10 Remove the covers or the plugs from the inlets of

the fuel injectors and, if relevant, from the unions of

the delivery valves of the fuel injection pump.

11 Put each high-pressure fuel pipe between its

delivery valv e and its fuel injector. Ensure that eac h

pipe lies naturally between its connections. Tighten

by hand each nut on to its relevant union. DO NOT

bend or distort a pipe to make it fit between its

connections. Tighten securely each nut to 45 Nm (33

lbf ft).

Note: Identification of each high-pressure fuel pipe is

made by the cylinder number which is stamped on the

union nut that is fitted on the fuel injector.

12 Fit new rubber dampers around each high-

pressure fuel pipe. Put the shrouds over the rubber

dampers and retain securely each shroud to its

induction manifold with bolts and spring washers.

To dismantle

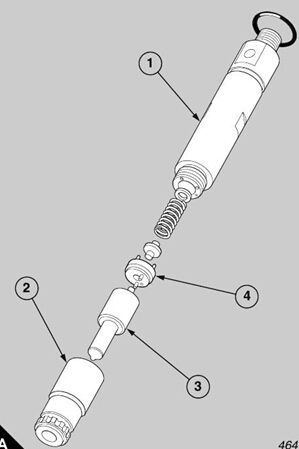

1 Hold lightly the body (A1) of the fuel injector in a

vice with soft covers and release the cap nut (A2).

Withdraw the assembly of the nozzle (A3), together

with the adaptor plate (A4), the valve seat, the valve

spring and the adjus tment shims. Keep together, in

their own tray, all the components of each injector.

Caution: Each nozzle needle is ground to the body

of its own noz zle and it is not interchangeable with

any other nozzle.

To assemble

1 Hold lightly the body of the injector in a vice and

insert the correct adjustment shims followed by the

valve spring and the seat. Fit the adaptor plate

around the seat.

2 If the nozzle and the noz zle needle are not

assembled, dip the components in clean ISO 4113

test oil and slide the valve fully into its location in the

nozzle. Fit the assembly to the adaptor plate and fit

the cap nut. Tighten the cap nut to 80 Nm (59 lbf ft).

3 For the fuel injec tors of early engines, fit the

connection for leak-off fuel, complete with a new

copper washer, into the body of the fuel injector. Do

not tighten fully the connection during this operation.

帕金斯柴油发动机喷油器清洁和检查

喷嘴CVK 508清洁套装

1 Wash the components of each injector in clean ISO

4113 test oil and dry with compressed air. Soak the

nozzle assembly in a carbon solvent such as ’Maxan

774’ which can be obtained from Henkel Chemicals

Limited, Edgeware Road, London.

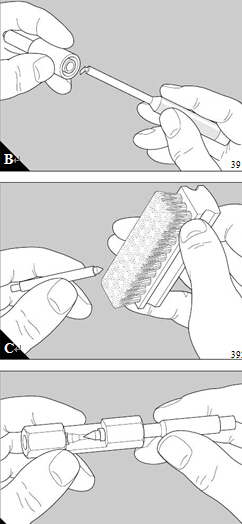

2 Use the cleaning kit CVK 508 (A,B,C,D and E) to

remove, from the nozzle and the nozzle needle, any

carbon which remains.

It is important that all carbon is removed from the

spray holes and that the correct size of wire from the

cleaning kit is used. The c ross-section of each wire

has a ’D’ shape and its size is measured across the

full diameter. Wires for the cleaning kit are available

in sets of five and can be supplied separately.

3 3 Fit the wire into its holder and ensure that the

protrusion is not more than 1,5 mm (0.0625 in). If the

protrusion is longer, there is a danger that the wire

may break in the hole. Insert the wire into each hole

and turn it to use it as a scraper, until the hole is clean.

Caution: Use only the tools supplied with the

cleaning kit to clean the assemblies of the nozzles. Do

not use any other device.

4 When all of the holes are clean, soak again each

nozzle in ’Maxan 774’, wash in clean water and dry

with compressed air and then dip in clean ISO 4113

test oil. If a device to flush the nozzles in a rev erse

direction is available, flush through each nozzle to

remove all particles that may still remain.

5 Use a magnifying lens to check the seats of

each

5用放大镜检查每个座位的座位

nozzle needle for roughness, distortion, or

other

喷嘴针的粗糙度,失真,或其他

damage. Check for worn holes in the nozzle

and

损伤。检查喷嘴内的磨损孔

check also the seat of each nozzle for

damage.

检查每个喷嘴的损坏位置。

Caution: If the faces of the nozzle needle or of

the

警告:如果喷嘴针的面或

nozzle show signs that they have been affected

by

喷嘴的迹象表明,他们已经受到影响

excessive temperature, both components must

be

温度过高,两个部件都必须

renewed. DO NOT try to lap a nozzle needle to

its

更新。不要试图将喷嘴针到它的

seat as they do not have the same

angles.

因为他们没有相同的角度。

6 Dip the nozzle needle into clean ISO 4113 test

oil

6将喷嘴针浸在4113个试验油中

and insert it into the bore of its nozzle. Slide

the

并将其插入其喷嘴孔中。滑动

nozzle needle fully into its location. Hold

almost

喷嘴针完全进入它的位置。拥有近

vertical the nozzle and withdraw approximately

one

垂直的喷嘴和撤回约1

third of the length of the nozzle needle from

the

第三的喷嘴针的长度从

nozzle. When it is released, the weight of the

nozzle

喷嘴。当它被释放时,喷嘴的重量

needle should cause it to slide down on to its

seat.

针应该使它滑到它的座位上。

7 If the nozzle needle is tight in the body of

the

7如果喷嘴针在体内的

nozzle, it is permissible to lap the stem of the

needle

喷嘴,它是允许的,以圈干的针

in the body of the nozzle. A special v ery

smooth

在车身的喷嘴。一个特殊的非常光滑

compound is available for this purpose from

the

化合物可用于此目的的

manufacturer of the fuel injectors.

燃油喷射器的制造商。

8

Inspect the faces between the body of the injector,

8检查喷油器本体之间的面,

the

adaptor plate and the nozzle for signs of scratc hes

适配器板和喷嘴的划痕他标志

or of

damage which could cause leakage under

或可能导致泄漏的损害

pressure.

压力。

9

Check the shims for damage and inspect the valve

9检查损坏的垫片和检查阀

spring for

distortion, damage or corrosion.

弹簧变形,损坏或腐蚀。

帕金斯柴油发动机喷油器的调整设置和测试

1 Use a test rig such as a ’Hartridge Injecta-centre’

to

1使用试验台如“哈特里奇注射液中心”

set the fuel injectors. Ensure that the container of

the

设置喷油器。确保容器的

test rig is filled with clean ISO 4113 test oil.

Loosen

试验台用洁净的异4113试验油。松开

the vent screw and operate the manual lever

until the

排气螺丝和操作手动杆,直到

flow of oil is free from bubbles. Tighten the vent

screw

流动的石油是免费的泡沫。拧紧排气螺钉

and continue to operate the manual lever until

the oil

并继续操作手动杆,直到油

which flows from the connection of the discharge

side

从放电侧的连接流

is also free from bubbles.

也没有气泡。

Warning! When an

injector is tested, the nozzle

警告!当喷油器测试时,喷嘴

must be away from the

operator because the oil which

必须远离运营商,因为石油

is sprayed has enough force to

pass through skin.

喷有足够的力量通过皮肤。

2 Fit the connection of the discharge side

of the test

2安装在测试的放电侧的连接

rig to the inlet of the injector and tighten

securely.

钻机到喷油器入口,并牢固地紧固。

Close the valve of the pressure gauge to

prevent

关闭压力表的阀门以防止

damage to the pressure gauge and operate

rapidly

损坏压力表和操作迅速

the manual pump to ex pel the air from the

fuel

前像素从燃料空气手动泵

injector. Open the valve of the pressure gauge

one

喷油器。打开压力表的阀门

quarter of a turn (90°), operate slowly the lever

and

四分之一的转(90),操作缓慢的杠杆和

make a note of the pressure at which the pointer

of

作一个说明,在该压力的指针

the pressure gauge moves suddenly to indicate

that

压力表突然移动以指示

the nozzle needle has opened. Unless

other

喷嘴针已打开。除非其他

information is given, the press ure should be 243

bar

信息是给定的,压力应该是243吧

(240 atmospheres) ± 5 bar.

(240个大气压)5巴。

3 If

the pressure of the injection is incorrect, the

fuel

3如果注射的压力不正确,燃料

injector must be dismantled and the shims must

be

喷油器必须拆除垫片必须

suitably adjusted. To increase the pressure, fit

extra

适当调整。增加压力,配合额外

shims; to reduce the pressure, remove some

shims.

垫片;减少压力,消除一些垫片。

4 When the correct setting is obtained, dry the tip

of

4当正确设置时,干燥

the nozzle and operate the pump slowly to raise

the

喷嘴和泵运转缓慢地提高

pressure until the pointer of the pressure

gauge

压力,直到压力表的指针

indicates 223 bar (220 atmospheres). Keep

this

指示223栏(220个大气压)。保持这

pressure for 10 seconds and then inspect the tip

of

压力为10秒,然后检查的尖端

the nozzle; a damp tip is acceptable but there

should

喷嘴;潮湿的顶端是可以接受的,但应该有

be no drops of oil.

无油滴。

Caution: Do not

overtighten the cap of the nozzle to

注意:不要过紧的喷嘴帽

try to correc t a

leakage.

要正确的泄漏。

5 To test for leakage with a back pressure, operate

the pump and raise slowly the pressure until the

pointer of the pressure gauge indicates 233 bar (230

the time that elapses for the pressure to reduce

naturally to 152 bar (150 atmospheres). If the time is

less than six seconds the nozzle assembly must be

discarded. Continue to refer to the pressure gauge

and make a note of the time that elapses for the

pressure gauge to indicate 101 bar (100

atmospheres). The time must not be less than 45

Before a nozzle ass embly is discarded, ensure that

the leakage is not caused by carbon or dirt on the

faces, and if there are a high number of failures,

check that the fault is not within the test rig. At regular

intervals, according to the amount of use, the filter

element of the test rig must be renewed and, if

necessary, fill the container of the test rig with new

test oil. It is recommended that the equipment is

checked for accuracy at intervals of not more than two

years.

6 To check the atomisation, close the valve of the

pressure gauge and operate the lever at a rate of

approximately two strokes during each second.

Check that there is complete atomisation of the oil

which sprays from each hole in the nozzle and that

the quantities of the oil from each of the holes are the

same. The nozzle tip should be dry after the oil has

been sprayed.

7 After the tests have been completed and the fuel

injectors are acceptable, dry the fuel injectors and fit

caps to protect the nozzles, the inlets and the

connections for the leak-off fuel. Put the fuel injectors

in a dry, warm place until they are needed.