帕金斯柴油发动机燃油泵、喷油器、滤清器燃油系统的谈细参数与维修保养技术参数资料

帕金斯柴油发动机燃油泵、喷油器、滤清器燃油系统的谈细参数与维修保养技术参数资料

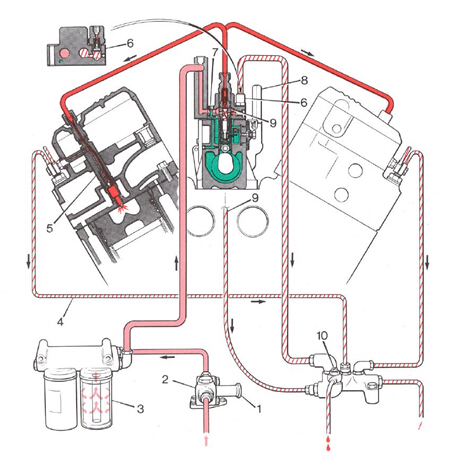

perkins帕金斯3012柴油发动机燃油系统的组成

General description

一般描述

The fuel

injection pump is a 12 element in-line unit

燃油喷射泵是一个12元列单元

driven at 0.5 x

engine speed by the timing gears. It is

在0.5×发动机转速的定时齿轮驱动。它是

fitted to a

plate in the crankcase ’V’.

安装在曲轴箱中的一个板上。

A constant s peed governor,

integral with the fuel

恒速调速器,与燃料积分

injection pump, maintains engine speed

through the

喷油泵,保持发动机转速通过

engine load range. The stop control on the

governor

发动机负荷范围。总督的停止控制

is connected directly to a solenoid, which is

actuated

直接连接到一个电磁线圈,这是致动的

by the stop button and the protection devices

of the

通过停止按钮和保护装置

engine. A vernier control is connected to the lever

of

发动机。游标控制连接到杠杆

the speed control for fine adjustment of engine

speed.

发动机转速精细调节的速度控制。

The end c overs on the ’CS’ governors are of

variable

C端接管的CS的州长是可变的

designs, according to the application. Each

cover

设计,根据应用。每个盖

includes an assembly of a servo-valve and, where

a

包括一个伺服阀组件,在那里

ramp is used which is not adjustable, the ramp

is

坡道是使用,这是不可调,坡道是

fastened to the inner wall of the cover.

Additional

系在盖的内壁上。额外的

differences are the positions for the connections

for

差异是连接的位置

the inlet (A1) and the outlet (A3) of the lubricating

oil.

入口(A1)和出口(A3)的润滑油。

Where necessary, a plug is fitted to give access

for

在需要的地方,安装一个插头以使接入

the adjustment of the ramp (A2).

坡道的调整(A2)。

As

seen from the rear of the engine, the shaft of the

从发动机的尾部看,轴的

fuel

injection pump rotates anti-clockwise. The pump

喷油泵逆时针旋转。泵

elements

operate in the sequence given below:

在下面给出的序列中的元素:

1, 9, 4, 11, 2, 7, 6,

10, 3, 8, 5 and 12 at 30 degree

30,9,4,11,2,7,6,10,3,8,5,12,1

intervals,

with No.7 element at the point of spill cutoff

间隔7元在泄漏截止点

(A6

injection).

(A6注射)。

The high-pressure fuel pipes are made from

special

高压燃料管是由特殊的

steel 8 mm diameter x 2 mm bore. Zinc plated

nuts

钢8毫米直径2毫米口径。镀锌螺母

and collars are fitted on both ends of each pipe.

The

和衣领都装在两端的每个管道。这个

relevant cylinder number is stamped on the nut at

the

有关汽缸编号是在螺母上加盖

pump end of the pipe.

管道泵端。

The low-pressure

system of fuel pipes is made from

燃油管的低压系统是由

mild steel, with connections

of union nuts and

轻微的钢,与连接螺母和

sleeves.

袖子。

For early engines, the

lift pump is driven by a cam on

对于早期的发动机,电梯泵是由凸轮驱动的

the rear end of the

auxiliary drive shaft. On new

辅助驱动轴的后端。在新的

engines, the fuel lift pump is

mounted at the front end

发动机,燃油泵安装在前端

of the engine within the engine vee

and is driven by

该发动机在发动机和驱动的V型

an additional cam lobe on the ’B’ bank

camshaft. The

“乙”银行凸轮轴上的凸轮轴。这个

lift pump draws fuel through a primary

filter from the

提升泵从所用的主过滤器中抽油

fuel tank before directing it through two

filter canisters

燃料箱前引导它通过两个过滤罐

to the gallery of the fuel injection

pump.

燃油喷射泵的图库。

Two low-pressure relief valves (A1) are fitted on the

body of the fuel

injection pump. They keep a constant

pressure of 90 to 117 kN/m (13 to 17

lbf/in ) in the

fuel supply to the gallery of the pump and allow the

surplus fuel to return to the fuel tank. Fuel enters the

elements of the

fuel injection pump and is sent at high

pressure, by the elements, to the 12

’low s pring’ type

of fuel injectors. The fuel injectors are set to operate

at 243 bar (240 atmospheres).

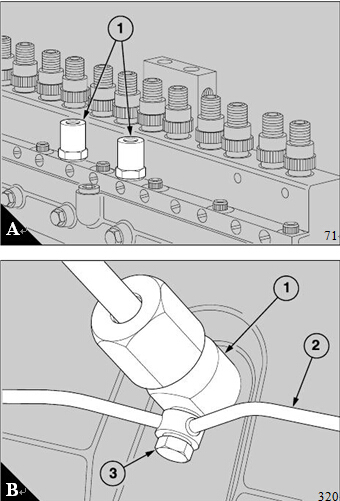

Early engines are fitted with Bosch or

OMAP fuel

injectors. New engines are fitted with composite

rocker

covers and these have Stanadyne fuel

injectors, as shown (B).

These fuel

injectors are longer than the other types to

allow the leak-off banjo

connections to be fitted

directly to the bodies of the fuel injec tors above

the

composite rocker covers. Other details are generally

similar to the

Bosch and the OMAP fuel injectors.

From the leak-off banjo connections a

system of pipes

directs the leak-off fuel to a connection block where it

mixes with the spill fuel and the surplus fuel from the

fuel injection

pump. It is then returned to the fuel tank.

The connection block has a vent

plug for the low-

pressure fuel system. For new engines the

connection

block is part of the fuel filter head.

Clean thoroughly each component, and

the area

around it, before it is dismantled or removed.

Fit suitable caps

and plugs to all of the unions

immediately after they have been dis

connected.

Components must be absolutely clean and kept

safely until

they are used during the maintenance or

the overhaul of the fuel system.

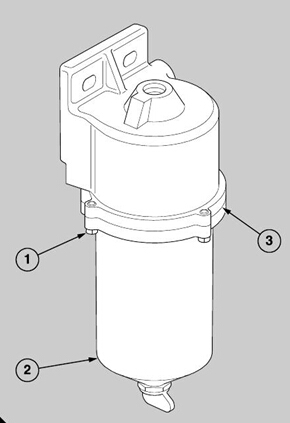

如何清洗帕金斯柴油初级燃油滤清器

Primary fuel filter

How to clean the primary fuel filter

1 Remove the

three bolts (A1) and remove the filter

bowl (A2).

2 Clean all of the

components with paraffin and dry

them with a compressed air jet.

3 Fit

the bowl to the filter head, together with a new

sealing ring. Align the

clamp ring (A3) and fasten it

with the three bolts.

Early engines can be

fitted with filters which have

elements that can be cleaned. These

elements

should be removed, cleaned with fuel oil and dried

with a

compressed air jet.

Fuel filter canisters

How to renew the canisters

of

the main fuel filter

On new engines the main fuel filter is fitted at the

rear

of the engine on the ‘A’ bank side. For early engines

it is fitted

to the 'B' bank side, against the cover of the

coolant gallery as shown

(B). The filter has two

disposable canisters. Both canisters must be

renewed at the same time.

1 Clean the area around the filter and remove

the fuel

filter canis ters. If neces sary, use a strap wrench.

Discard

the canisters.

2 Check that the sealing ring (B1) is fitted correctly to

each new canister and clean the contact faces of the

filter head.

3

Lubricate the top of the canister seal (B1) with clean

fuel oil and renew

the sealing ring (B2) on the adaptor.

4 Fit the new canisters to their

threaded adaptors and

tighten each canister until the sealing ring just

comes

into contact with the filter head. Continue to tighten

overtighten.

After the fuel filter canisters have been renewed,

eliminate air from the low pressure fuel system as

given in operation

20-16.

Fuel filter head

The fuel filter head is fitted at the rear of the engine

on the ’A’ bank side. For early engines the fuel filter

head is fitted to the ’B’ bank side, against the cover of

the coolant gallery.

To remove

1 Remov e the two fuel filter canisters.

Caution: Do NOT bend any of the fuel pipes.

2 Disconnect the fuel leak-off pipes from the fuel filter

head. Remove the pipes if relevant to the job.

3 Disconnect the three low pres sure fuel pipes from

the fuel filter head. Remove the pipes if relevant to

the job.

4 Hold the fuel filter head and remove the two bolts

and nuts. Withdraw the bolts and collect the spacers

and washers.

To fit

1 Fit the fuel filter head to the air filter bracket and

retain it with the two bolts and nuts complete with

spacers and plain and spring washers. The spacers

must be fitted between the fuel filter head and the air

filter bracket. Tighten the nuts to a torque of 23 Nm

(17 lbf ft).

2 Fit the three low pressure fuel pipes. Use new

copper sealing washers.

3 Fit the fuel leak-off pipes. Use new copper sealing

washers.

4 Fit the two fuel filter canisters, see operation 20-2.

5 Eliminate air from the low pressure fuel system as

given in operation 20-16.