Perkins汽缸体和气缸套维修装拆的标准技术参数

Perkins汽缸体和气缸套维修装拆的标准技术参数

Perkins汽缸体和气缸套维修装拆的标准技术参数

General description

一般描述

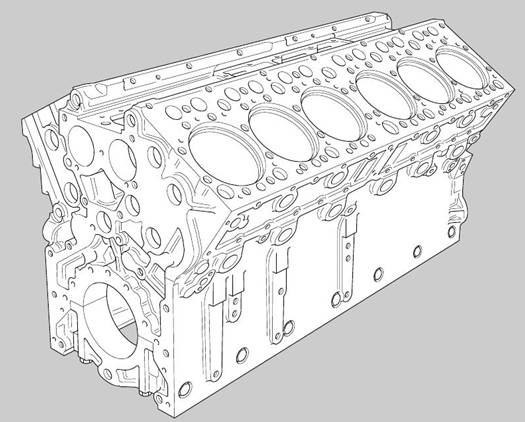

The crankcase (A and B) is a monobloc casting made

曲轴箱(A和B)是一个整体铸造

from high quality cast iron. The casting is dipped in a

高质量铸铁。铸件被浸在一个

special sealing compound to prevent contamination

防止污染的专用密封化合物

and to seal all surfaces which are not machined. The

密封所有未加工的表面。这个

first illustration (A) shows the front of the crankcase

首先说明(一)显示曲轴箱的前面

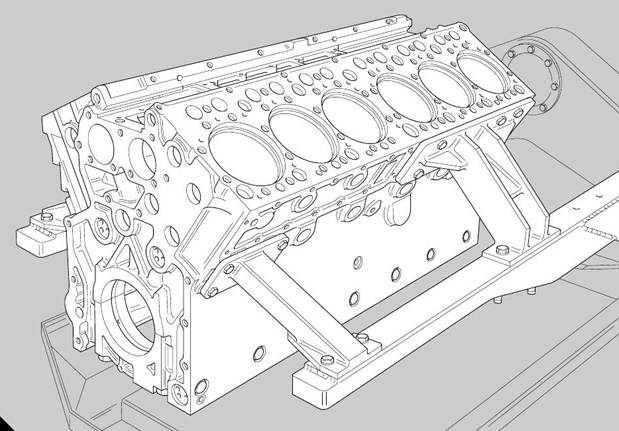

and the second illustration (B) shows the rear of the

二插图(乙)显示后方

crankcase.

曲轴箱。

The top of the crankcase has two banks of six

曲轴箱的顶部有两家银行的六

cy linders which make a ’V’ arrangement at an

CY该使“V”安排在一个

included angle of 60 degrees. The cylinder banks are

夹角60度。气缸组是

not symmetrical on the crankcase and ’B’ bank is

在曲轴箱和'乙'银行不是对称的

nearer to the front of the engine. The bores of the

靠近Perkins3012发动机的前部。孔的

cy linders are machined to receive dry cylinder liners.

CY该加工得到干式气缸套。

Galleries in the casting of the cylinder block supply a

在气缸体的铸造中的画廊

flow of coolant around each c ylinder bore. Small

在每一个确定的冷却液流孔。小

holes are drilled through each flame face to supply

通过每一个火焰面钻孔钻

coolant to the cylinder heads.

冷却液到气缸盖。

The crankcase has housings for seven main

曲轴箱有七个主要的外壳

bearings. Each assembly of the main bearings is

轴承。各组件的主轴承是

retained by a bearing cap made from a steel forging.

由钢锻件制成的轴承盖。

The bearing c aps at the centre and at each end of the

轴承C APS在中心和在每个结束

engine are fitted with four bolts. Each of the remainder

Perkins3012发动机装有四个螺栓。其余的

of the bearing caps are assembled with two bolts.

用两根螺栓装配的轴承盖。

To ensure that the bearing caps are rigid, side bolts

为确保轴承盖刚性,侧螺栓

are fitted through the side walls of the crankcase into

通过安装在曲轴箱的侧壁上

location pads on each side of the bearing caps. All oil

轴承盖的每一侧的位置垫。所有的油

galleries are drilled to ensure that the bores are

画廊以确保孔钻

accurate and clean.

准确和干净。

The twelve dry liners are a fine clearance fit in the

这十二个干衬里是一个很好的间隙配合的

crankcase. They have flanges at the upper ends and

曲轴箱。它们在上两端有法兰

are retained in their respective cylinder bores by the

被保留在各自的气缸

four cylinder heads.

四缸头。

Each liner is made of cast iron by a centrifugal

每一个衬垫是由离心铸造的铸铁制成的

process. The degree of hardness is varied along its

过程。硬度的程度是多种多样的

length and the internal diameter is machined by

长度和内部直径的机械加工

special processes to obtain a surface finish which will

特殊工艺,获得表面光洁度,这将

reduce wear and consumption of oil. The upper face

减少机油消耗。上脸

of each bank of cylinders has bores for 24 tappets.

各银行对24缸挺杆孔。

The camshaft bearings are rolled bushes, of the split

凸轮轴轴承是一个滚动的衬套,其拆分

type, and are pre-finished. They have steel bac ks

类型,并预先完成。他们有钢BAC KS

and bearing surfac es of lead bronze. The bearings do

轴承表面的铅青铜。轴承做

not need normally a special procedure except to

一般不需要特别程序

ensure that they are cleaned thoroughly during the

确保他们被彻底清除

overhaul.

检修。

Crankcase

曲轴箱

7 Disconnect and remove the exhaust pipes.

7断开并拆下排气管。

8 Disconnect the electrical system between the stop

8断开电气系统

solenoid, the coolant temperature switch and the oil

电磁阀、冷却液温度开关和机油

pressure switch, and the main control panel.

压力开关,主控板。

9 Remove the radiator, operation 21-1.

9拆下散热器,运行21-1。

10 Fit the lift plate CV 8012 to the flywheel housing

10安装在飞轮壳上的提升板8012

with two bolts and the spring washers.

用两根螺栓和弹簧垫圈。

11 Use the universal lift adaptor VP 8364 and a

11使用通用电梯适配器副总裁8364

suitable hoist to hold the assembly of the engine.

合适的提升机以保持Perkins3012发动机的装配。

Build stand - engine VP 5908 which also includes:

建立支架-Perkins3012发动机副总裁5908,其中也包括:

Mounting brackets - crankcase

安装支架-曲轴箱

’B’ bank rear VP 5597

'乙'银行后副总裁5597

’A’ bank rear VP 5598

'一'银行后副总裁5598

’A’ bank front VP 6836

'一'银行前副总裁6836

’B’ bank front VP 6837

'乙'银行前副总裁6837

Universal lift adaptor VP 8364

通用电梯适配器副总裁8364

Lift plate CV 8012

升降板8012

To fit to a build stand

适应一个建立的立场

To obtain access to the crankcase and further main

获得进入曲轴箱和进一步的主要

components, the engine must be disconnected from

组件,Perkins3012发动机必须被断开

its driven unit and fitted in a build stand. Instructions

它的驱动单元,并安装在一个建立的立场。指令

to disconnect the driven unit are to be found in the

要断开驱动单元,在

publication of the relevant manufacturer. To fit the

有关制造商的出版物。适合

engine in a build stand, proceed as follows:

Perkins3012发动机在一个建立的立场,进行如下:

1 Disconnect the batteries.

1断开蓄电池。

2 Close the valves and disconnect the pipes for the

2关闭阀门,切断管道

fuel supply and the fuel return. Remove and discard

燃料供给和燃料回流。清除和丢弃

the two filter canisters.

两个过滤罐。

3 To drain the cooling system, remove the drain plugs

3要排空冷却系统,拆卸排水塞

from the radiator, from the outlet pipe of the coolant

从散热器,从出口管的冷却液

pump, from the front of ’A’ bank and from the rear of

泵,从'一'银行和从后方

’B’ bank of the crankcase.

曲轴箱的乙组。

4 Drain the lubricating oil from the engine by the

4将润滑油从Perkins3012发动机中排出

removal of the drain plug from the base of the sump.

排水槽底部的泄放塞。

5 Drain the engine lubricating oil from the heat

5排出Perkins3012发动机润滑油

exchanger by the removal of the drain plug at the rear

换热器通过拆卸后的泄放塞

end. Put a container below the filter canisters to

结束。放在过滤罐容器

receive the oil which drains from the heat exchanger.

接收来自换热器的油。

6 Lubricating oil which remains in the heat exchanger

6润滑油在热交换器中保持

can be drained by the removal of the three filter

可以排出的三个过滤器的去除

canisters. Use the strap wrench, 21825 825, to

罐。使用带扳手,825 21825,以

remov e and discard the filter canisters.

清除和丢弃过滤罐。

12 Disconnect the support brackets from the flywheel

12断开飞轮支架的支架

housing, and the front mountings from the base

住房,从底座的前支架

frame.

框架。

If not relevant to the job, the front mountings may be

如果没有相关的工作,前支架可

retained on the fan adaptor.

保留在风扇适配器。

13 Lift the assembly of the engine from the mountings

13升Perkins3012发动机的装配与安装

and lower it on to the floor of the workshop with

并将它放在车间的地板上

suitable wooden supports beneath the flywheel

在飞轮下的合适的木支撑

housing.

住房。

Before the engine is fitted in the build stand and

在Perkins3012发动机安装在建造支架和

subsequently dismantled, clean it thoroughly and

随后拆除,彻底清除

ensure that the cooling and lubrication systems are

确保冷却和润滑系统

drained completely.

排空。

14 Remove the air filters and their support brackets,

14拆下空气滤清器及其支架,

and the inlet ducts for the turbochargers.

与涡轮增压器的进气管。

15 If relevant to the job, releas e the three bolts which

15如果与工作有关,释放三螺栓

retain the starter motor. Withdraw the starter motor.

保留起动器电机。撤回起动电机。

16 Remove the fan, operation 21-8.

16拆下风扇,运行21-8。

17 If relevant to the job, remove the fan belts and the

17如果与工作相关,拆下风扇皮带和

tensioner pulley, operation 21-9.

张紧轮、工作队。

18 If relevant to the job, remove the crankshaft pulley,

18如果与工作有关,拆下曲轴皮带轮,

the damper and the alternator pulley, operation 14-1.

减振器和发电机皮带轮,运行14-1。

Caution: The damper is a heavy component and

警告:该阻尼器是一个沉重的组成部分和

must not be allowed to fall during removal, because

不得在拆除过程中,因为

distortion of the casing can prevent its correct

套管变形能防止其正确

19 Remove the front covers of the coolant galleries

19拆下冷却液展览馆的前盖

and fit the four mounting brackets to the crankcase as

将四个安装支架安装到曲轴箱上

at the front of ’A’ bank over the front

在前面的“一”银行在前面

coolant gallery

冷却水道

at the front of ’B’ bank over the front

在前面的'乙'银行在前面

coolant gallery

冷却水道

on the bosses at the rear of ’A’ bank

在“银行”后方的老板

on the bosses at the rear of ’B’ bank

在'乙'银行后方的老板

1 If relevant, fit the lift plate CV 8012 to the flywheel

1如有相关,安装在飞轮上的提升板8012

housing with two bolts and spring washers.

双螺栓和弹簧垫圈的住房。

2 Remove the eight bolts and nuts, whic h retain the

2拆下八个螺栓和螺母,它保留

mounting brackets to the arms of the build stand, and

将托架安装到支架的臂架上,并且

use the universal lift adaptor VP 8364 and a suitable

使用通用电梯适配器副总裁8364和一个合适的

hoist to remove the engine from the build stand.

从建造支架上拆下Perkins3012发动机。

Lower the engine on to the floor of the workshop with

将Perkins3012发动机降低到车间的地板上

suitable wooden s upports beneath the flywheel

适用于木制的支持下飞轮

housing.

住房。

Caution: Ensure that the plug in the boss at the rear

注意:确保在后面的老板的插头

of ’A’ bank has been removed before the mounting

在安装前,银行已被拆除

bracket VP 5598 is fitted.

安装支架5598。

20 Use the lift adaptor VP 8364 to put the engine in

20使用电梯适配器副总裁8364将Perkins3012发动机放在

the build stand VP 5908 with the flywheel at the outer

在外的飞轮的建设的立场副总裁5908

end. Fit the eight bolts, which retain the mounting

结束。安装八个螺栓,该螺栓保留安装

brackets, through the arms of the build stand as

支架,通过手臂的建立作为

shown (A), fit the nuts and tighten sec urely. Remove

(一)所示,将螺母拧紧秒肯定。删除

the universal lift adaptor.

通用电梯适配器。

3 Clean thoroughly the blanking plug which was

3清洗彻底的落下插头

removed from the rear of ’A’ bank. Apply some

从“银行”的后方取。应用一些

’Loc tite 542’ to the blanking plug and ensure that it is

“组委会有542的堵塞和确保它是

fitted to the boss when the mounting bracket VP 5598

安装在安装支架的副总裁5598

is removed.

除去。

4 Remove the four mounting brackets from the

4拆下四安装支架

crankcase and use new joints to fit the front covers of

曲轴箱和使用新接头以配合前盖

the coolant galleries.

冷却液画廊。

5 If relevant, fit the crankshaft pulley, the damper and

5如果相关的话,安装曲轴皮带轮、减震器和

the alternator pulley, operation 14-1.

发电机皮带轮,运行14-1。

6 If relevant, fit the assembly of the tensioner pulley

6如果相关,合适的张紧轮的装配

and fit loosely the fan belts, operation 21-9.

和松配合风扇皮带,操作队。

7 Fit the fan and tighten the fan belts, operation 21-9.

7安装风扇和风扇皮带紧,工作队。

8 If relevant, fit the front mountings to the fan adaptor.

8如果相关,安装前安装的风扇接头。

9 Fit the starter motor and retain it with the three

9配合Perkins3012发动机的起动电机,并将其与三

bolts.

螺栓。

10 Fit the inlets of the turbochargers, the air filters

10安装的涡轮增压器的进气口,空气过滤器

and their support brackets.

以及他们的支持。

11 Use the universal lift adaptor VP 8364 to lift the

11使用通用电梯适配器副总裁8364

assembly of the engine over the base frame and

Perkins3012发动机组件的基础框架和

lower carefully the engine. Connect the support

小心引擎。连接支持

brackets to the flywheel housing and the front

在飞轮壳和前支架

mountings to the base frame. Remove the lift

支架的底座。拆下电梯

adaptor.

适配器。

12 Fit the radiator, operation 21-1.

12安装散热器,运行21-1。

13 Connect the electrical system between the main

13连接电气系统之间的主要

control panel and the stop solenoid, the coolant

控制面板和停止电磁,冷却液

temperature switch and the oil pressure switch.

温度开关和油压开关。

14 Install and connect the exhaust pipes.

14安装和连接排气管。

15 Fit the drain plugs in the base of the lubricating oil

15在润滑油的基础上安装排水塞

sump and at the rear end of the heat exchanger.

集油器和热交换器的后端。

16 Fill the filter canisters with clean engine lubricating

16填充过滤罐清洁Perkins3012发动机润滑

oil and fit them on to the adaptors of the bracket for

油和适合他们的支架转接器

the filter head, until the seal on each canister is just in

过滤器的头,直到每个罐上的密封只是在

contact with its face. Tighten by hand each canister a

接触面。用手拧紧每罐

further 1 /4 turns. Do NOT overtighten.

进一步1 / 4匝。不要过紧。

17 If the engine lubricating oil can be used again,

17如果Perkins3012发动机润滑油可再次使用,

return it to the sump of the engine and fill the sump

把它返回到Perkins3012发动机的油底壳,然后灌满油底壳

with new and clean oil to the ’Full’ mark on the

用新的和清洁的油,以“满”的标记

dipstick, if necessary.

油尺,如果必要的话。

18 Fit the drain plugs for the coolant to the front of ’A’

18安装在“一”的前面的冷却液的漏极插头

bank and to the rear of ’B’ bank of the crankcase, to

银行和“乙”银行的曲轴箱,以

the outlet pipe of the coolant pump and to the radiator.

冷却液泵和散热器的出口管。

Check that the drain plugs are secure and fill the

检查泄放塞是否安全并填充

cooling system. Add more coolant, of the same

冷却系统。添加更多的冷却液,相同

specification as that already in use, if neces sary.

规范,已经在使用,如果有必要。

Check for leakage in the system.

系统中的泄漏检查。

19 Fit two new fuel filter canisters on to the adaptors

19安装两个新的燃油滤罐上的接头

of the filter head, until the seal on each canister is just

的过滤器的头,直到每个罐的密封只是

in contact with its face. Tighten by hand each canister

在接触面。用手拧紧每罐

the pipes and open the valves for the fuel supply and

管道和阀门的燃料供应和

the fuel return. Check for leakage in the sys tem.

燃料回流。在系统中检查泄漏。

20 Release the two bolts and the spring washers

20松开两根螺栓和弹簧垫圈

which retain the lift plate CV 8012 on the flywheel

其中,在飞轮上保留电梯板的简历8012

housing and remove the lift plate.

起升板。

21 Connect the engine to its driven unit, in

21将Perkins3012发动机连接到其驱动单元

accordance with the instructions which are to be

按照指示,这是

found in the publication of the relevant manufacturer.

发现在有关制造商的出版物。

22 Connect the batteries.

22连接电池。

To dismantle and to assemble

拆卸和组装

To dismantle

拆除

1 Fit the assembly of the engine in the build stand,

1装配Perkins3012发动机的装配,在建立架,

operation 16-1.

操作16-1。

It is recommended that the smaller items, (for

建议较小的项目,(对

example, low-pressure fuel pipes, clips, brackets ,

例如,低压燃料管,夹子,支架,

etc.) have labels to indicate their location and their

等)有标签,以表明其位置和他们的

purpose, and are put in containers with relevant

目的,并与相关的容器

engine parts.

Perkins3012发动机零件。

2 Disconnect and remove the coolant pipes from

2断开并拆下冷却液管

between the coolant gallery of 'A' bank, the coolant

之间的冷却剂库“一”银行,冷却液

pump and the heat exchanger.

泵和热交换器。

3 Disconnect and remove the coolant pipe from

3断开并拆下冷却液管

between the front cover of the coolant gallery on 'B'

在“乙”的冷却液库的前盖之间

bank and the outlet of the heat exchanger.

热交换器的出口。

4 Disconnect and remove the pipe between the

4断开并拆下管道之间的

coolant pump and the thermos tat housings.

冷却液泵和恒温器的外壳。

5 Remove the fuel injectors, operation 20-7.

5拆下喷油器,操作20-7。

6 Remove the fuel injection pump, operation 20-8.

6拆下喷油泵,操作20-8。

7 Remove the cylinder heads, operation 12-9.

7拆下气缸盖,操作12-9。

8 Remove the two blanking plates and the mounting

8拆下2个消落板及安装

for the fuel injection pump from the 'V' of the

为燃油喷射泵从“伏”的

crankcase.

曲轴箱。

9 Lift out the tappets and make temporary marks to

9取出挺杆和临时标志

indicate their positions when the crankcase is

在曲轴箱时指示其位置

assembled.

组装。

10 Hold the cylinder liners with the retainers, 21825

10将缸套与家臣,21825

844.

844。

11 Remove the fan adaptor, operation 21-10

11拆下风扇接头,操作21-10

12 Remove the flywheel and the flywheel housing,

12拆下飞轮和飞轮壳,

operation 22-4.

操作中可以看到。

13 Remove the timing case, operation 15-5.

13拆下正时箱,操作15-5。

14 Remove the camshafts, operation 17-1.

14拆卸凸轮轴,操作人。

15 Remove the lubricating oil sump, operation 19-1

15拆下油池润滑,运行19-1

or, for new engines, operation 19-5.

或者,新的引擎,运行19-5。

16 For early engines, remove the sump adaptor,

16为早期的Perkins3012发动机,拆卸油底壳适配器,

operation 19-3.

操作19-3。

17 Remove the lubricating oil pump, operation 19-7.

17去除润滑油泵,手术197。

18 Remove the assemblies of the pistons and the

18拆下活塞和活塞组件

connecting rods, operation 13-3 paragraph 8.

连接杆,操作13-3 8款。

19 Remove the crankshaft, operation 14-4 paragraph

19拆下曲轴,14-4段操作

12 to 14.

12至14。

20 Remove the piston cooling jet assemblies.

20拆下活塞冷却喷嘴组件。

21 Remove the retainers. Withdraw carefully each

21拆下的扣件。退出小心

liner and put it with its own assembly of piston and

班轮,并把它与自己的活塞组装

connecting rod.

连杆。

22 Remove the rear covers of the coolant galleries,

22拆下冷却液展览馆的后盖,

the fuel filter head, operation 20-3, and the heat shield

燃油滤头,操作20-3,和热屏蔽

for the filter head.

对于过滤头。

23 If the camshaft bearings are to be renewed, the

23如果凸轮轴轴承要换新

cup plugs at the front ends of the camshaft bores

杯插头前端的凸轮轴孔

must be removed.

必须除去。

24 If the crankcase is to be tested under pressure,

24如果在压力下进行曲轴箱,

remove the eight bolts and nuts, which retain the

删除八个螺栓和螺母,保留

mounting brackets to the arms of the build stand. Use

将托架安装到支架的臂架。使用

a hoist and a suitable rope sling to remove the

一个提升机和一个合适的绳吊,以除去

crankcas e from the build stand.

从建立独立的曲轴箱。

25 Remove the four mounting brackets from the

25拆下四安装支架

crankcas e.

曲轴箱E.

To assemble

组装

1 If the crankcase has been tested under pressure

1如果曲轴箱在压力下进行了测试

and it is acceptable, fit the four mounting brack ets to

这是可以接受的,符合四安装制动系统

the crankcase. Use a hoist and a suitable rope sling

曲轴箱。使用一个提升机和一个合适的绳吊

to lift the crankcase and put it in the build stand VP

将曲轴箱提起并把它放在建立副总裁

5908. Ensure that the end of the crankcase to which

5908。确保曲轴箱的末端

the timing case is fitted is furthest from the build

时间的情况下安装是最远的构建

stand.

站。

Note: The weight of the crankcase is approximately

注:曲轴箱的重量约为

620 kg (1367 lb).

620公斤(1367磅)。

2 Fit each piston cooling jet assembly onto the

2将每个活塞冷却喷嘴安装到

relevant studs in the crankcase, fit the spring washers

在曲轴箱中的相关螺栓,安装弹簧垫圈

and nuts on the studs and lightly tighten the nuts.

和螺母在螺栓上,轻轻拧紧螺母。

Check that the top faces of the banks of the

检查银行的顶面

cylinders and all of the cylinder liners are clean. The

气缸和所有的气缸套都是干净的。这个

number of its respective cylinder is etched on each

其各自的气缸的数目被蚀刻在每个

cylinder liner, and the numbers should be toward the

气缸套,和数字应该朝向

centre of the engine when the cylinder liners are

当气缸套是Perkins3012发动机的中心

ins erted.

INS插入。

3 Insert each cylinder liner in its respective cylinder

3将各气缸套在其相应的气缸内

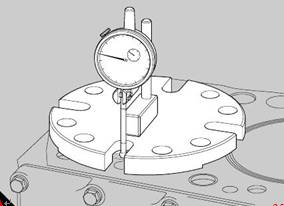

bore. Use the check plate, 21825 786, and the dial

孔。使用检查板,786 21825,和拨号

gauge and holder, 21825 787, to check the protrusion

仪表和支架,787 21825,以检查突出

of the cylinder liners above the top faces of both

在这两个顶面上的气缸套

banks of cylinders. Ensure that the check plate and

气缸组。确保检查板和

the holder for the dial gauge are clean.

表盘上的支架是干净的。

4 Put the check plate over the first cylinder liner and

4把检查板放在第一个气缸套和

put the holder of the dial gauge on the checking plate.

把表盘的支架放在检查板上。

Put the button of the dial gauge on the top face of the

把表盘上的按钮放在顶部

bank of cylinders and set the dial gauge to zero (A).

气缸组和设置的刻度盘为零(一)。

Caution: The check plate may be held on the top

警告:检查盘可以在顶部举行

face of the bank of cylinders by two of the bolts which

用螺栓连接的气缸组

retain a cylinder head, if the top face is not horizontal.

保留一个气缸盖,如果顶面不水平。

5 Put carefully the button of the dial gauge onto the

5小心把刻度盘上的按钮放在

top face of the flange of the first cylinder liner, at four

第一气缸套的凸缘的顶面,在四

different locations. Each correct location for the

不同的位置。每个正确的位置

button is shown (A). Make a note of the deflection,

按钮显示(一)。作一个挠度的说明,

from zero, for each location.

从零开始,为每个位置。

6 Move the check plate to the other cylinder liners in

6将止回板移到另一个气缸套

rotation and check their protrusions. Compare the

旋转和检查他们的突起。比较

readings which have been obtained with the

已获得的读数

protrusions shown (A).

突出显示(一)。

Caution:

谨慎:

l The protrusion for each cylinder liner must be

为每个气缸套的凸起必须是

between 0,076 mm and 0,127 mm (0.003 in and

在0076毫米和0127毫米之间(0.003和

0.005 in).

0.005)。

l The variation of protrusion around the

周围的突起的变化

circumference of a liner must not exceed 0,025

衬垫的圆周不得超过0025

mm (0.001 in).

毫米(0.001英寸)。

l The variation of protrusion between the nearest

之间的距离的变化的最接近

points of two cylinder liners which are next to each

下一个气缸套的点

other must not exceed 0,025 mm (0.001 in).

其他不得超过0025毫米(0.001英寸)。

l The maximum difference in the protrusions under

l在突起的最大差异在

one cylinder head must not exceed 0.051 mm

一缸头不得超过0.051毫米

(0.002 in).

(0.002)。

l Banks shown as A1 will be acceptable. Banks

银行表现为A1是可以接受的。银行

shown as A2 are not acceptable.

如A2是不可接受的。

16

十六

7 Renew a cylinder liner if its protrusion is not correct.

7更换气缸套,如果其突出是不正确的。

Inspect the seat of the flange of the new cylinder liner,

检查新气缸套的法兰座的位置,

operation 16-5. Check its protrusion also.

操作16-5。检查它的突出。

8 When their protrusions have been checked, make

8当他们的突起已检查,使

temporary marks to indicate the exact position of each

临时标记以指示每个

flange in the crankcase and remove the cylinder

在曲轴箱中的凸缘并拆下气缸

liners. Immediately before the work proceeds, clean

衬垫。工作前立即进行清理,清洁

the top of each bank of cylinders, degrease and dry

每一排汽缸顶部、脱脂、干燥

the cylinder liners and the recesses for the flanges of

气缸套和法兰的凹槽

the cylinder liners.

气缸套。

9 Apply a bead of ’Hylomar PL 32/M’ (medium grade)

9涂”可以PL 32 / M(中等)

to the seat under the flange of each c ylinder liner.

每个C内衬里法兰下的座位。

Remove the surplus from the faces on the side. Allow

从侧面上移除多余的剩余。允许

the compound to partially dry, align the temporary

该化合物部分干燥,对齐的临时

marks and insert, without rotation, each cylinder liner

没有旋转的标志和插入物,每一个气缸套

in its bore in the crankcase. Do not subsequently

在曲轴箱的孔中。后来不

allow the ’Hylomar’ seal to be broken.

让“可以”印章被打破。

10 Use the bolts of the cylinder heads to fit eight

10使用气缸盖的螺栓配合八

retainers, 21825 844, to ensure that the cylinders

家臣,21825 844,确保气瓶

liners remain in their positions when the assemblies of

当组件的装配时,衬垫留在他们的位置

the pistons and the connecting rods are fitted.

活塞和连杆都装。

Caution:

谨慎:

Ensure that oil, which may contaminate the

确保油,可能会污染

26 Fit the cylinder heads, operation 12-9.

26安装汽缸盖,操作12-9。

compound, is not subsequently applied to the top

复合后,未被应用到顶部

faces of the banks of cylinders before the cylinder

气缸前的气缸面

heads are fitted. Ensure also that the seal, which is

头装。确保密封件,这是

made by the compound, is not subsequently broken.

由该化合物制成,不随后被打破。

11 Fit the rear covers of the coolant galleries, the

11安装冷却液展览馆的后盖

heat shield for the fuel filter head and the fuel filter

燃油滤清器头和燃油滤清器的热屏蔽

head, operation 20-3.

头,操作20-3。

12 Fit the crankshaft, operation 14-4 paragraph 1 to

12安装曲轴,操作14-4 1款

16.

16。

13 Fit the as semblies of the pistons and the

13适合作为活塞的拆卸和

connecting rods, operation 13-3.

连接杆,操作13-3。

14 Fit the timing case, operation 15-5 paragraphs 1

14安装正时箱,操作15-5段落1

to 10.

10。

15 Fit the camshafts, operation 17-1 paragraphs 1, 2,

15安装凸轮轴,操作17-1段落1、2,

4 to 17.

4至17。

16 If relevant, clean the contact face for each cup

16如果有相关的话,为每一杯的接触面清洁

plug in the camshaft bores and apply ’Loctite 542’ to

插入凸轮轴孔和适用的Loctite 542”

the outer wall of a c up plug. Use the replacer tool

一个碳上插头的外壁。使用替代工具

from the kit, 21825 866, to fit the cup plug into the

从试剂盒,866 21825,以适应杯塞到

camshaft bore of ’B’ bank until the lip of the cup plug

“乙”的凸轮轴孔直到杯塞的唇

is aligned precisely with the face at the front end of the

在前面的正面与正面对齐

crankcase (B).

曲轴箱(乙)。

17 Apply enough clean engine lubricating oil to

17应用足够的清洁Perkins3012发动机润滑油

lubricate the tappets, and also the bores for the

润滑挺杆,并为孔

tappets. Slide each tappet into its respective bore, in

挺杆。滑动挺杆插入其各自的孔,在

accordance with the temporary markings.

根据临时标记。

18 Fit the two blanking plates and the mounting for

18安装2个消落板和安装

the fuel injection pump, with their joints, in their

燃油喷射泵,其接头,在其

locations in the ’V’ of the crankcase. Retain the

曲轴箱中的“V”位置。保留

mounting with the six bolts and their spring washers.

安装有六个螺栓和弹簧垫圈。

Tighten each bolt to 40 Nm (30 lbf ft).

拧紧每个螺栓40牛米(30磅英尺)。

Caution: Ensure that the bolts are of the correct

警告:确保螺栓的正确性

length, and that there is clearance between the ends

长度,并在两端之间有间隙

of the bolts and the bushes of the camshafts, to

的螺栓、凸轮轴衬套,以

prevent damage to the bushes.

防止损坏的灌木丛。

19 Fit the timing gears and the auxiliary drive shaft,

19配合正时齿轮和辅助传动轴,

operation 15-1.

操作15-1。

20 Fit the flywheel housing and the flywheel,

20配合飞轮壳和飞轮,

operation 22-4.

操作中可以看到。

21 Fit the fan adaptor, operation 21-10.

21安装风扇接头,操作21-10。

22 Fit the lubricating oil pump, operation 19-7.

22适合的润滑油泵,运行197。

23 For early engines, fit the sump adaptor, operation

23早期的Perkins3012发动机,安装油底壳接头,操作

19-3.

19-3。

24 Fit the lubricating oil sump, operation 19-1 or, for

24合适的润滑油,操作或为19-1,

new engines, operation 19-5.

新的引擎,运行19-5。

25 Remove the retainers, 21825 844, which retain

25拆下扣件,21825 844,保留

the cylinder liners.

气缸套。

Fits and clearances

配合与间隙

Cylinder liners in crankcase

曲轴箱的气缸套

Fits and clearances

配合与间隙

Cylinder liners in crankcase

曲轴箱的气缸套

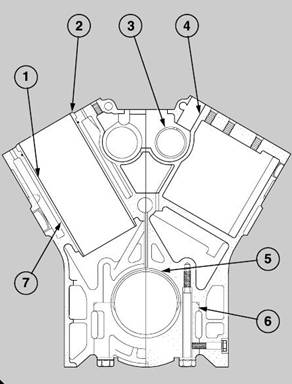

Bore of crankcas e (A7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140,488 to 140,513 mm (5.5310 to 5.5320 in)

E的曲轴箱孔(A7)。..............................140488至140513毫米(5.5310至5.5320)

Diameter of cylinder liner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140,449 to 140,475 mm (5.5295 to 5.5305 in)

气缸套直径。............................140449至140475毫米(5.5295至5.5305)

Clearance (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,013 to 0,064 mm (0.0005 to 0.0025 in)

间隙(新)。......................................0013至0064毫米(0.0005至0.0025)

Depth of counterbore in crankcase (nominal) . . . . . . . . . . . . . . . . 11,900 to 11,930 mm (0.4685 to 0.4696 in)

在曲轴箱的沉孔深度(名义)。..............11900至11930毫米(0.4685至0.4696)

Depth of flange of cylinder liner (nominal) . . . . . . . . . . . . . . . . . . . 12,000 to 12,025 mm (0.4724 to 0.4734 in)

气缸套(公称)法兰的深度。..................12000至12025毫米(0.4724至0.4734)

Protrusion of cylinder liner (A2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,0760 to 0,127 mm (0.003 to 0.005 in)

缸套突出(A2)。............................00760至0127毫米(0.003至0.005)

Caution: Cylinder liners must be selected for their fit to obtain the limits for correct protrusion.

警告:必须选择气缸套,以获得正确的突出的限制。

Cylinder liners out of crankcase

在曲轴箱中的气缸套

Bore of c ylinder liner (A1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135,000 to 135,025 mm (5.3150 to 5.3159 in)

C内缸套孔(A1)。............................135000至135025毫米(5.3150至5.3159)

Permissible worn dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135,306 mm (5.3270 in)

允许磨损尺寸。..........................................135306毫米(5.3270英寸)

Tappets in crankcase

挺杆在曲轴箱

Bore in crankc ase (A4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36,000 to 36,025 mm (1.4173 to 1.4183 in)

孔crankc ASE(A4)。................................36000至36025毫米(1.4173至1.4183)

Diameter of tappet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35,959 to 35,975 mm (1.4157 to 1.4163 in)

挺杆直径。....................................35959至35975毫米(1.4157至1.4163)

Clearance (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0,025 to 0,066 mm (0.001 to 0.0025 in)

间隙(新)。........................................0025至0066毫米(0.001至0.0025)

Permissible worn clearance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.075 mm (0.0029 in)

容许磨损间隙。..............................................0.075毫米(0.0029英寸)

Bearings of camshaft in crankcase

曲轴箱中凸轮轴的轴承

Bore in crankc ase (A3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71,500 to 71,530 mm (2.8150 to 2.8161 in)

孔crankc ASE(A3)。................................71500至71530毫米(2.8150至2.8161)

Diameter of bearing of camshaft . . . . . . . . . . . . . . . . . . . . . . . . . . 71,590 to 71,640 mm (2.8185 to 2.8205 in)

凸轮轴轴承直径。........................71590至71640毫米(2.8185至2.8205)

Interference (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.060 to 0.140 mm (0.0023 to 0.0055)

干扰(新)。........................................0.060至0.140毫米(0.0023至0.0055)

Refer to the illustration (A) on page 116.

参考图116页(页)。

Housing of main bearing in crankcase

主轴承在曲轴箱

Bore of housing for bearing (A5) . . . . . . . . . . . . . . . . . . . . . . . . 152,000 to 152,025 mm (5.9842 to 5.9852 in)

孔住房轴承(A5)。......................152000至152025毫米(5.9842至5.9852)

Bearing caps in crankcase

曲轴箱轴承盖

Width of location for bearing cap (A6) . . . . . . . . . . . . . . . . . . . . 236,000 to 236,025 mm (9.2913 to 9.2923 in)

轴承盖的位置宽度(A6)。..................236000至236025毫米(9.2913至9.2923)

Width of bearing cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236,000 to 236,013 mm (9.2913 to 9.2918 in)

轴承盖的宽度。................................236000至236013毫米(9.2913至9.2918)

Transition fit (new) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . -0,013 to +0,025 mm (-0.0005 to +0.001 in)

过渡配合(新)。....................................0013到0025毫米(-0.0005 + 0.001)