详细描述

John Deere约翰迪尔强鹿柴油机气缸套的拆卸检查与标准值参数

IMPORTANT: If liner pitting has occurred, checkcondition of coolant.

NOTE: When installing reusable liners, rotate 90° fromoriginal position. The liners should be deglazedand ring sets installed in pistons.

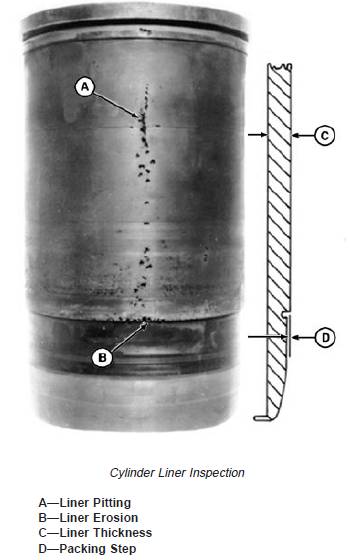

1. Inspect exterior length of liner for pitting (A). Checkpacking step for erosion (B). If pitting or erosion isobserved, measure depth of pits with a fine wire orneedle. Replace piston and liner if:

· Depth of any pit is one-half or more of liner thickness(C).

· Depth of erosion is one-half or more of the packingstep (D).

Specification

Cylinder Liner—Thickness 6.23—6.89 mm(0.25—0.27 in.)

Cylinder Liner Packing Step—Dimension 2.02—2.29 mm(0.08—0.09 in.)

2. Visually inspect liner ID. Replace piston and liner if:

· The crosshatch honing pattern is not visible immediately below the top ring turn-around area for turbocharged engines.

· The hone pattern is not visible all the way around the liner in over 75 percent of the ring travel area for naturally aspirated engines.

· Liners are pitted or contain deep vertical scratches that can be detected by the fingernail.

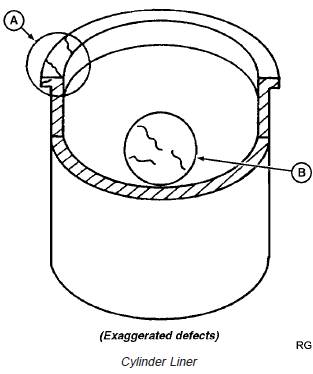

3. Carefully examine liner for signs of fatigue, such as fine cracks in the flange area (A) and cracks in the ring

travel area (B).

NOTE: Inspect block for cracks or erosion in the O-ring packing areas. (See INSPECT AND CLEAN CYLINDER BLOCK later in this group.)

A—Flange Area

B—Ring Travel Area

John Deere约翰迪尔强鹿柴油机缸套的清洗方法

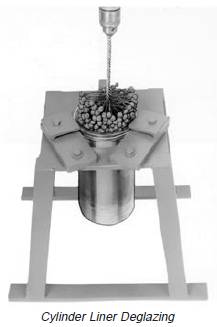

1. Secure cylinder liner in a holding fixture. (See DealerFabricated Service Tools, Section 05, Group 190 for assembly of holding fixture.)

2. Use D17004BR Flexible Cylinder Hone to deglazecylinder liner.

NOTE: Use honing oil along with flex hone when deglazing liners.

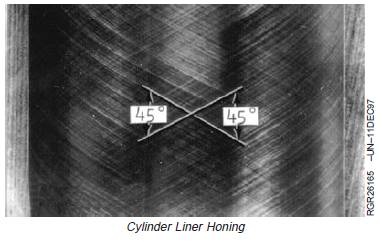

3. Use D17004BR Hone according to instructions supplied with tool to obtain a 45° cross-hatch pattern.Thoroughly clean liners after deglazing. See CLEAN CYLINDER LINERS earlier in this group for proper cleaning procedures.

400-100-8969 15088860848

0574-26871589 15267810868

0574-26886646 15706865167

0574-26871569 18658287286

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文(简)

中文(简) Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska