详细描述

John Deere约翰迪尔强鹿柴油机恒温节温器和检查测试

Visually inspect thermostat for corrosion or damage.

Replace as necessary.

Test thermostat as follows:

CAUTION: DO NOT allow thermostat or

thermometer to rest against the side or bottom

of container when heating water. Either may

rupture if overheated.

1. Remove thermostats. (See procedure in Section 02,

Group 070.)

2. Suspend thermostat and a thermometer in a container

of water.

3. Stir the water as it heats. Observe opening action of

thermostat and compare temperatures with

specification given in chart below.

NOTE: Due to varying tolerances of different suppliers,

initial opening and full open temperatures may

vary slightly from specified temperatures.

THERMOSTAT TEST SPECIFICATIONS

Rating Initial Opening (Range) Full Open

(Nominal)

71°C (160°F) 69—72°C (156—162°F) 84°C (182°F)

77°C (170°F) 74—78°C (166—172°F) 89°C (192°F)

82°C (180°F) 80—84°C (175—182°F) 94°C (202°F)

89°C (192°F) 86—90°C (187—194°F) 101°C (214°F)

90°C (195°F) 89—93°C (192—199°F) 103°C (218°F)

92°C (197°F) 89—93°C (193—200°F) 105°C (221°F)

96°C (205°F) 94—97°C (201—207°F) 100°C (213°F)

99°C (210°F) 96—100°C (205—212°F) 111°C (232°F)

4. Remove thermostat and observe its closing action as it

cools. In ambient air the thermostat should close

completely. Closing action should be smooth and slow.

5. If any thermostat is defective on a multiple thermostat

engine, replace all thermostats.

John Deere约翰迪尔强鹿柴油机冷却系统和散热器压力测试

CAUTION: Explosive released fluids from

pressurized cooling system can cause

serious burns.

Shut off engine. Only remove filler cap when

cool enough to touch with bare hands.

Slowly loosen cap to first stop to relieve

pressure before removing completely.

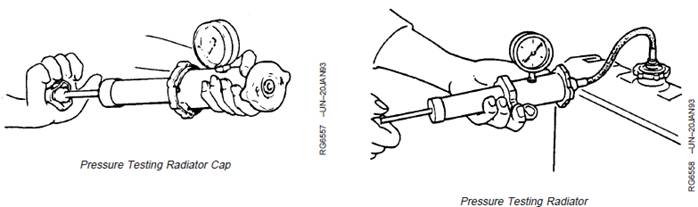

Test Radiator Cap:

1. Remove radiator cap and attach to D05104ST

Pressure Pump as shown.

2. Pressurize cap to the following specification1.

Two-Valve Head Engines and 4.5 L Four-Valve Head Engines—

Specification

Radiator Cap2—Holding

Pressure (10 Second Minimum

Hold) 70 kPa (0.7 bar) (10 psi)

Minimum

............................................................

6.8 L Four-Valve Head Engines—Specification

Radiator Cap3—Holding

Pressure (10 Second Minimum

Hold) 100 kPa (1.0 bar) (15 psi)

Minimum

..........................................................

Gauge should hold pressure for 10 seconds within the

normal range if cap is acceptable.

If gauge does not hold pressure, replace radiator cap.

3. Remove the cap from gauge, turn it 180°, and

retest cap. This will verify that the first

measurement was accurate.

Test Cooling System:

NOTE: Engine should be warmed up to test overall

cooling system.

1. Allow engine to cool, then carefully remove radiator

cap.

1Test pressures recommended are for all Deere OEM cooling

systems. On specific vehicle applications, test cooling system and

pressure cap according to the recommended pressure for that

vehicle.

26068HF275 Industrial OEM with VP44 pump use a radiator cap with

a pressure specification 100 kPa (1.0 bar) (15 psi) minimum.

36068HF475 for gen-set applications use a radiator cap with 70 kPa

(0.7 bar) (10 psi) minimum.

2. Fill radiator with coolant to the normal operating

level.

IMPORTANT: DO NOT apply excessive pressure to

cooling system. Doing so may

damage radiator and hoses.

3. Connect gauge and adapter to radiator filler neck.

Pressurize cooling system to specification listed for

radiator cap.1, using D05104ST Pressure Pump.

4. With pressure applied, check all cooling system

hose connections, radiator, and overall engine for

leaks.

If leakage is detected, correct as necessary and

pressure test system again.

If no leakage is detected, but the gauge indicated a

drop in pressure, coolant may be leaking internally

within the system or at the block-to-head gasket.

1Test pressures recommended are for all Deere OEM cooling

systems. On specific vehicle applications, test cooling system and

pressure cap according to the recommended pressure for that

vehicle.

John Deere约翰迪尔强鹿柴油机气缸盖垫片故障检查

NOTE: Booklet DB1119—CYLINDER HEAD GASKET

FAILURES for 6466 and 6076 Engines can be

used as a guide for diagnosing head gasket

failures on POWERTECHâ 4.5 L and 6.8 L

Engines. However, use specifications provided in

this manual (CTM104).

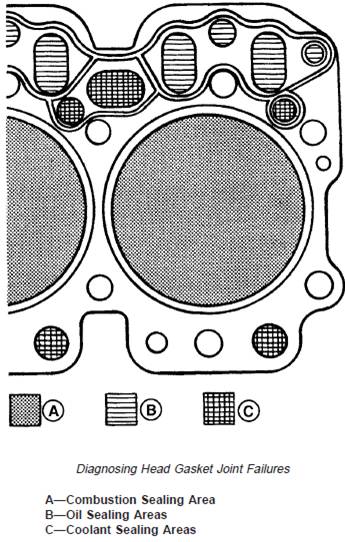

Head gasket failures generally fall into three categories:

· Combustion seal failures.

· Coolant seal failures.

· Oil seal failures.

Combustion seal failures occur when combustion gases

escape between cylinder head and head gasket

combustion flange, or between combustion flange and

cylinder liner. Leaking combustion gases may vent to an

adjacent cylinder, to a coolant or oil passage, or

externally.

Coolant or oil seal failures occur when oil or coolant

escapes between cylinder head and gasket body, or

between cylinder block and gasket body. The oil or

coolant may leak to an adjacent coolant or oil passage, or

externally. Since oil and coolant passages are primarily on

right-hand (camshaft) side of engine, fluid leaks are most

likely to occur in that area.

Follow these diagnostic procedures when a head gasket

joint failure occurs or is suspected.

1. Before starting or disassembling engine, conduct a

visual inspection of machine and note any of the

following:

· Oil or coolant in head gasket seam, or on adjacent

surfaces. Especially right rear corner of gasket joint.

· Displacement of gasket from normal position.

· Discoloration or soot from combustion gas leakage.

· Leaking radiator, overflow tank, or hoses.

· Leaking coolant from coolant pump weep hole.

· Damaged or incorrect radiator, fan, or shroud.

· Obstructed air flow or coolant flow.

· Worn or slipping belts.

· Damaged or incorrect pressure cap.

· Presence of oil in coolant.

· Low coolant levels or Improper coolant.

· Unusually high or low oil levels.

· Oil degradation, dilution, or contamination.

· Incorrectly specified injection pump.

· Indications of fuel or timing adjustments.

· Unburned fuel or coolant in exhaust system.

2. Obtain coolant and oil samples for further analysis.

3. Start and warm up engine if it can be safely operated.

Examine all potential leakage areas again as outlined

previously. Using appropriate test and measurement

equipment, check for the following:

· White smoke, excessive raw fuel, or moisture in

exhaust system.

· Rough, irregular exhaust sound, or misfiring.

· Air bubbles, gas trapped in radiator/overflow tank.

· Loss of coolant from overflow.

· Excessive cooling system pressure.

· Coolant overheating.

· Low coolant flow.

· Loss of cab heating (air lock).

4. Shut engine down. Recheck crankcase, radiator, and

overflow tank for any significant differences in fluid

levels, viscosity, or appearance.

5. Compare your observations from above steps with the

diagnostic charts earlier in this group. If diagnostic

evaluations provide conclusive evidence of combustion

gas, coolant, or oil leakage from head gasket joint, the

cylinder head must be removed for inspection and

repair of gasket joint components.

COMBUSTION SEAL LEAKAGE

Symptoms:

· Exhaust from head gasket crevice

· Air bubbles in radiator/overflow tank

· Coolant discharge from overflow tube

· Engine overheating

· Power loss

· Engine runs rough

· White exhaust smoke

· Loss of cab heat

· Gasket section dislodged, missing (blown)

· Coolant in cylinder

· Coolant in crankcase oil

· Low coolant level

Possible Causes:

· Insufficient liner standout

· Excessive liner standout differential between cylinders

· Low head bolt clamping loads

· Rough/damaged liner flange surface

· Cracked/deformed gasket combustion flange

· Out-of-flat/damaged/rough cylinder head surface

· Missing/mislocated gasket fire ring

· Block cracked in liner support area

· Excessive fuel delivery

· Advanced injection pump timing

· Hydraulic or mechanical disturbance of combustion seal

NOTE: Cracked cylinder head or liners may also allow

combustion gas leakage into coolant.

COOLANT SEAL LEAKAGE

Symptoms:

· Coolant discharge from head gasket crevice

· Coolant in crankcase oil

· Low coolant level

· High oil level

· Coolant discharge from crankcase vent

Possible Causes:

· Excessive liner standout

· Excessive liner standout differential between cylinders

· Low head bolt clamping loads

· Out-of-flat/damaged/rough block surface

· Out-of-flat/damaged/rough cylinder head surface

· Oil or coolant overheating

· Cracks/creases in gasket body surfaces

· Damage/voids in elastomer beading

OIL SEAL LEAKAGE

Symptoms:

· Oil discharge from head gasket crevice

· Oil in coolant

· Low crankcase oil level

· Reduced oil to rocker arms (noisy)

Possible Causes:

· Excessive liner standout

· Excessive liner standout differential between cylinders

· Low head bolt clamping loads

· Out-of-flat/damaged/rough block surface

· Out-of-flat/damaged/rough cylinder head surface

· Oil or coolant overheating

· Cracks/creases in gasket body surfaces

· Damage/voids in elastomer beading

· Damaged/missing O-ring seal at oil port to rocker arms

NOTE: Defective oil cooler may also allow oil leakage into

coolant.

400-100-8969 15088860848

0574-26871589 15267810868

0574-26886646 15706865167

0574-26871569 18658287286

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文(简)

中文(简) Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska