详细描述

TableofContents

Specifications Section

EngineDesign .....................................................

FuelTransferPump .............................................

FuelFilterBase ....................................................

FuelFilter(Primary) ..............................................

FuelPrimingPump ..............................................

Electronic UnitInjector ..........................................

Electronic UnitInjectorMechanism .....................

Electronic UnitInjectorRockerArm......................

Electronic UnitInjectorWiring...............................

ValveMechanism .................................................

ValveMechanism Cover ......................................

4

4

5

5

6

6

7

7

8

9

9

Cylinder HeadValves ........................................... 10

Cylinder Head ...................................................... 11

Turbocharger ........................................................ 13

Exhaust Manifold ................................................. 13

Exhaust Elbow ..................................................... 14

Camshaft ............................................................. 14

EngineOilFilterBase .......................................... 15

EngineOilPump .................................................. 16

EngineOilPan ..................................................... 17

WaterLines........................................................... 17

WaterTemperatureRegulator Housing ................ 18

WaterTemperatureRegulator .............................. 18

WaterPump ......................................................... 19

Cylinder Block ...................................................... 19

Cylinder Liner ....................................................... 21

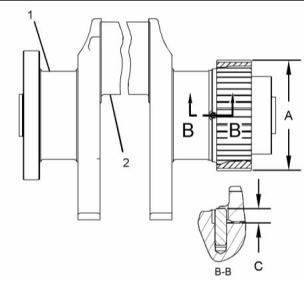

Crankshaft ........................................................... 21

Crankshaft Seals ................................................. 22

Vibration Damper ................................................. 22

Connecting RodBearingJournal ......................... 23

MainBearingJournal ............................................ 23

Connecting Rod ................................................... 24

PistonandRings .................................................. 24

PistonCooling Jet................................................. 25

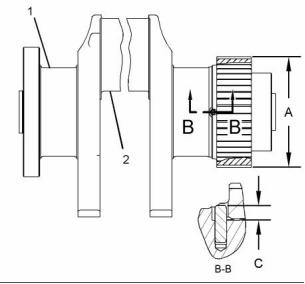

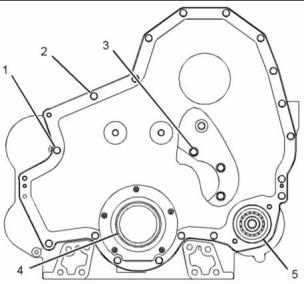

Housing (Front)..................................................... 26

GearGroup(Front) ............................................... 27

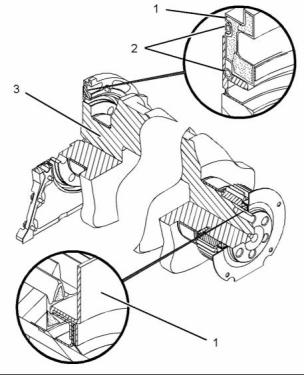

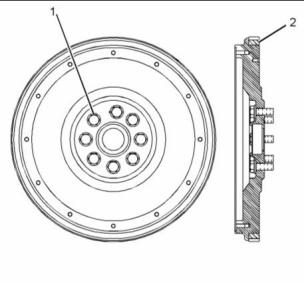

Flywheel ............................................................... 28

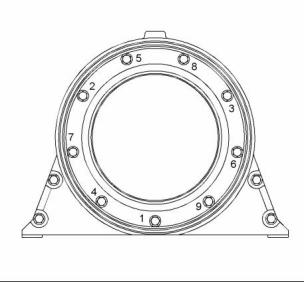

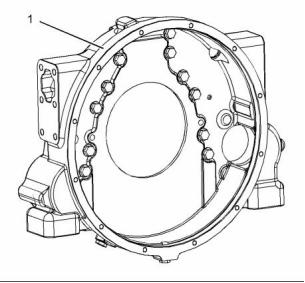

Flywheel Housing ................................................ 28

Flywheel Housing Cover ...................................... 28

BeltTightener ....................................................... 29

FanDrive ............................................................. 29

Alternator andRegulator ...................................... 30

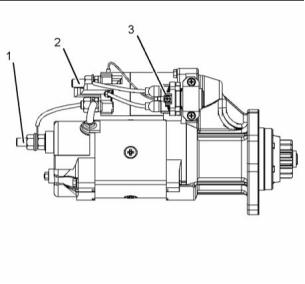

Electric StartingMotor ......................................... 30

Coolant TemperatureSensor ............................... 31

FuelTemperatureSensor ..................................... 31

EngineOilPressure Sensor ................................. 32

Atmospheric PressureSensor .............................. 32

InletAirTemperatureSensor ................................ 32

InletManifold AirPressure Sensor ....................... 32

Speed/Timing Sensor .......................................... 33

Index Section

Index ..................................................................... 34

This document is printed from SPI². Not for RESALE

![]()

4

Specifications Section

KENR6905

SpecificationsSection

i02576024

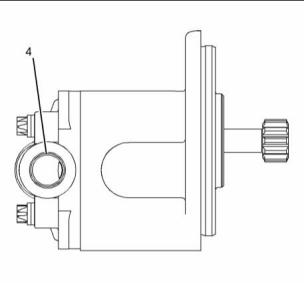

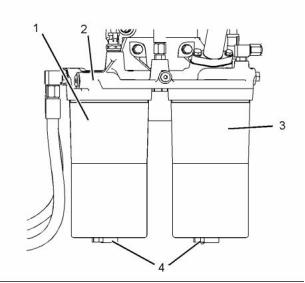

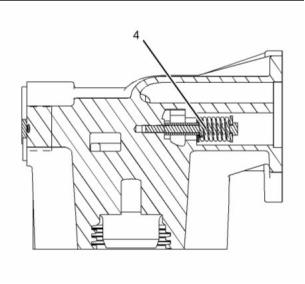

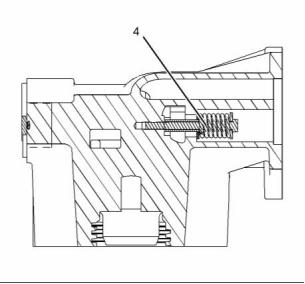

FuelTransferPump

i02796848

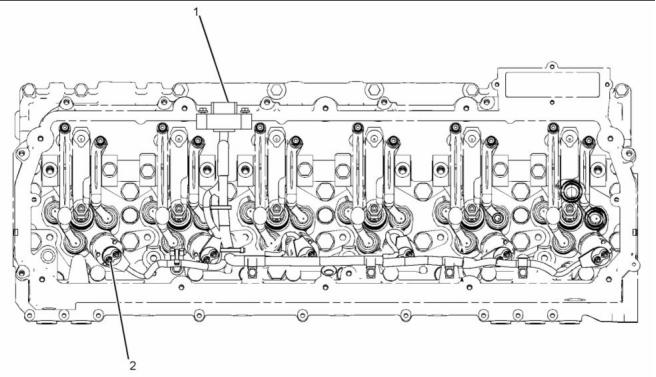

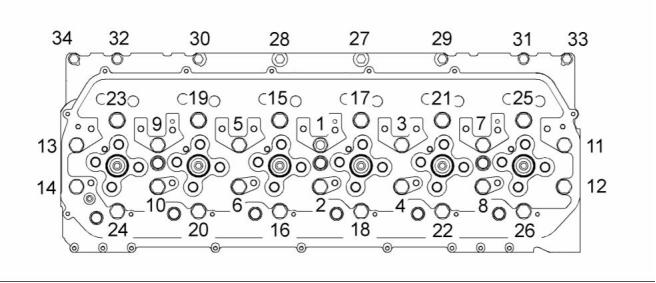

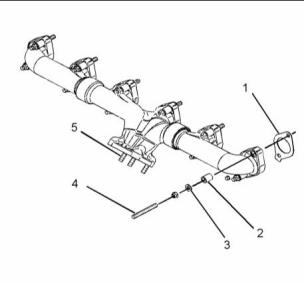

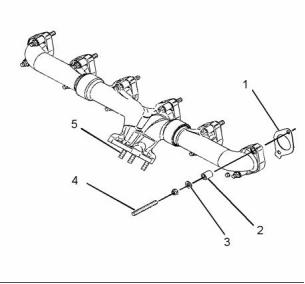

EngineDesign

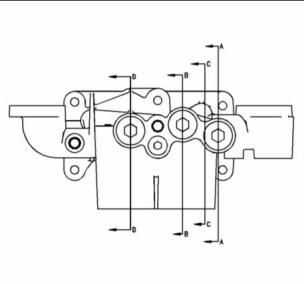

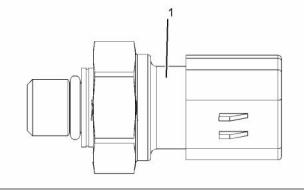

g01320504

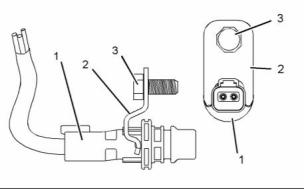

Illustration 2

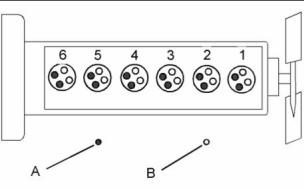

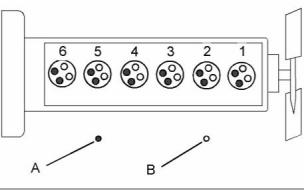

g01193927

Illustration 1

Cylinder and valve location

(A) Inlet

(B) Exhaust

Bore ........................................... 130mm(5.12inch)

Stroke ........................................ 157mm(6.12inch)

Displacement .................................... 12.5L(763in)

3

Cylinder arrangement .................................... In-Line

Valvespercylinder.................................................. 4

Theadjustment fortheinletvalvelashisthefollowing

value. .............. 0.38±0.08mm(0.015±0.003inch)

The adjustment forthe exhaust valve lash isthe

following value. ................................ 0.64±0.08mm

(0.0252 ±0.0031 inch)

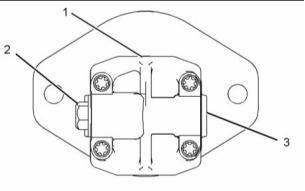

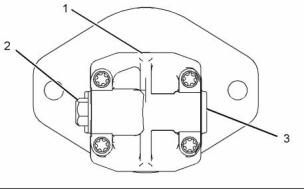

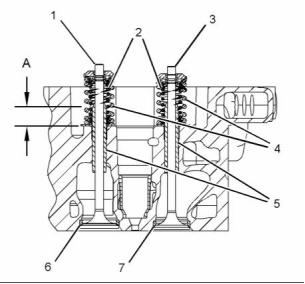

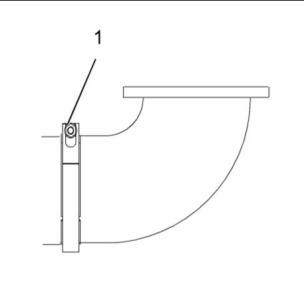

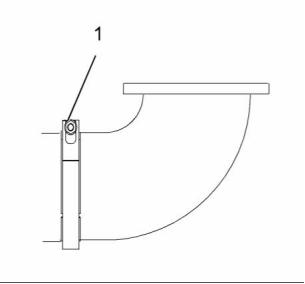

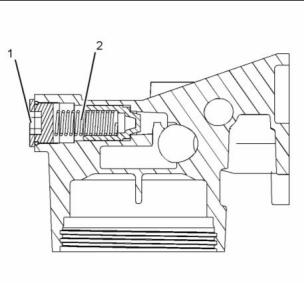

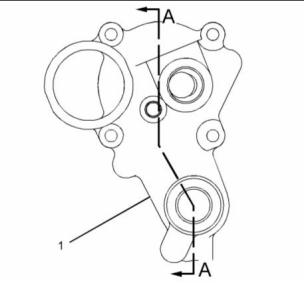

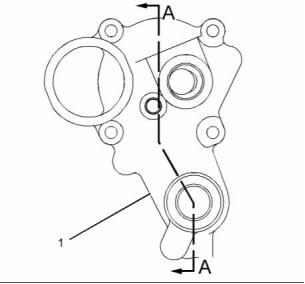

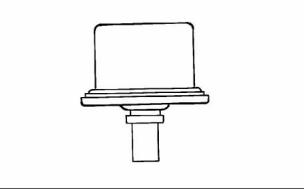

g01320507

Illustration 3

(1) Weep hole

(2) Pressure regulating valve

(3) Outlet port

Typeofcombustion........................... DirectInjection

Firingorder(injection sequence) ........ 1,5,3,6,2,4

Crankshaft rotation ....................... Counterclockwise

(4) Inlet port

Whenthefueltransfer pumpisusingdieselfuel,the

fueltransferpumphasthefollowing specifications:

1. Run the pump at 2940 rpm. The full bypass

Note: Thefront endoftheengine isopposite the

flywheel end.Theleftsideandtherightsideofthe

engine areviewed fromtheflywheel end.TheNo.1

cylinder isthefront cylinder.

pressureshouldbe716to786kPa(104to114psi).

2. Runthepump at840rpm.Theflowat550kPa

(80psi)mustbe3.0L/min(0.8USgpm).

3. Runthepumpat2940rpm.Theflowat650kPa

(94psi)mustbe4.5L/min(1.19USgpm).

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR6905

5

Specifications Section

4. Runthepumpat120rpm.Keeptheinletopento

theatmosphere for10seconds. Block theinlet.

Thepump mustmaintain thevacuum of30kPa

(4.5psi)minimum in30seconds.

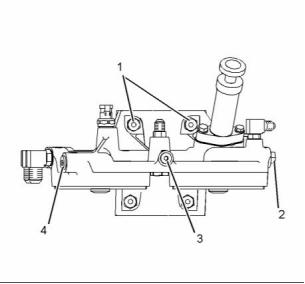

i02797008

FuelFilter(Primary)

5. Runthepumpat840rpm.Keeptheinletopento

theatmosphere for10seconds. Block theinlet.

Thepump must maintain thevacuum of45kPa

(6.5psi)minimum in30seconds.

Table1

Required Tools

Part Number

CV60889

6. Runthepumpat120rpmwithablocked inletfor

30seconds. Thepumpinletmusthaveasuction

liftof60.9kPa(18InHg)minimum.

Tool

Partdescription

A

POWERPART

Special

Lubricant

When thepump isviewed from thedrive end,the

rotation ofthepumpiscounterclockwise.

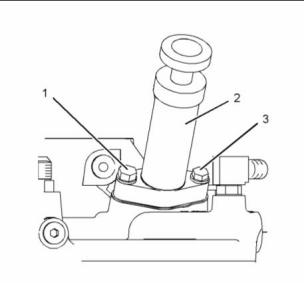

i02797015

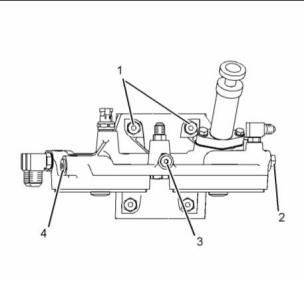

FuelFilterBase

g01287986

Illustration 5

Typical example

(1) Apply Tooling(A)tothethreads oftheprimary

fuelfilterhousing. Tightentheprimary fuelfilter

housing (1) to the fuel filter base (2) to the

following torque. ..........80±10N·m(59±7lbft)

(2) Fuel filter base

g01287856

Illustration 4

(3) ApplyTooling(A)tothethreads ofthesecondary

fuel filter housing. Tighten thesecondary fuel

filterhousing (3)tothefuelfilterbase(2)tothe

following torque. ..........80±10N·m(59±7lbft)

(1) Retaining setscrews ................. 47N·m(35lbft)

(2) Plug ........................................... 15N·m(11lbft)

(3) Plug ........................................... 15N·m(11lbft)

(4) Plug .......................................... 41N·m(30lbft)

(4) Drain Plugs

This document is printed from SPI². Not for RESALE

![]()

![]()

6

Specifications Section

KENR6905

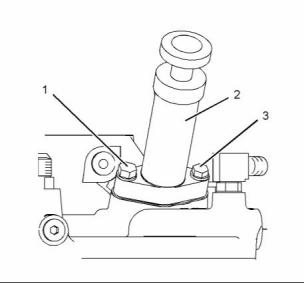

i02797020

i02902879

FuelPrimingPump

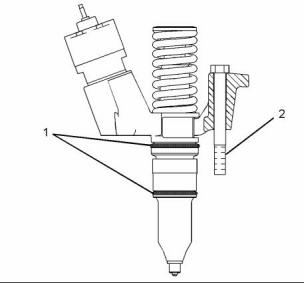

ElectronicUnitInjector

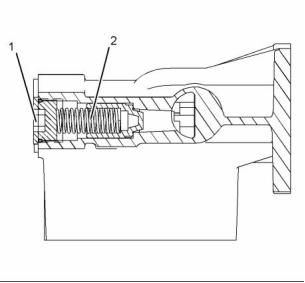

g01287938

g01091593

Illustration 6

Illustration 7

Typical example

(1) Lubricate the seals and the bore with clean

engine oil.

(1) Tightenthebolttothefollowing torque....25N·m

(220 lbin)

(2) Bolttorque ...................55±10N·m(40±7lbft)

(2) Priming pump

(3) Tightenthebolttothefollowing torque....12N·m

(105 lbin)

This document is printed from SPI². Not for RESALE

![]()

KENR6905

7

Specifications Section

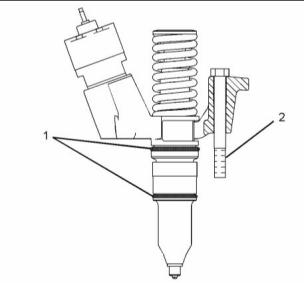

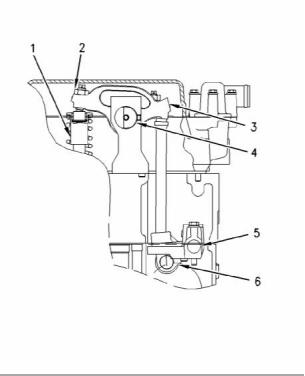

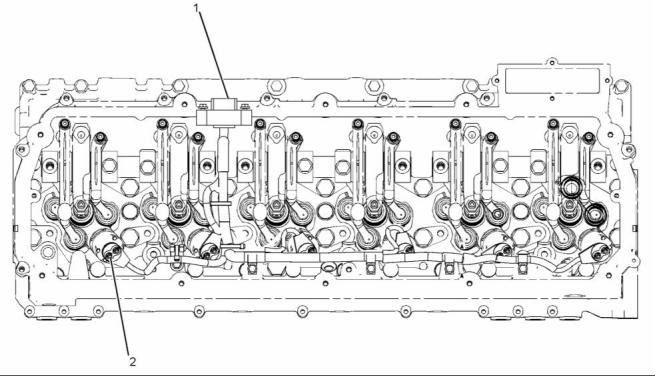

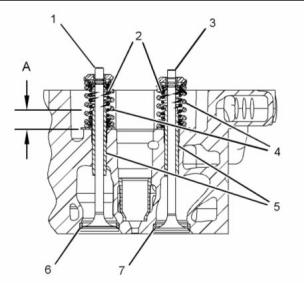

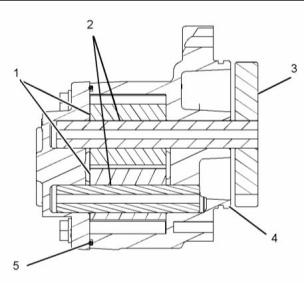

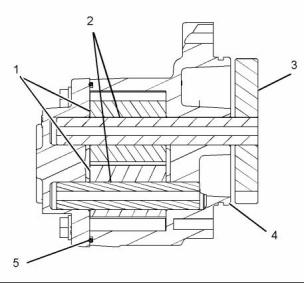

i02796843

2. Turntheadjustment screwclockwise. Stopturning

theadjustment screwwhencontact ismadewith

theelectronic unitinjector (1).

Electronic Unit Injector

Mechanism

3. Turntheadjustment screw clockwise.

Turn ........................... 180degrees (1/2ofaturn)

4. Holdtheadjustment screw.

Tighten the locknut (2) to the following

torque............................ 55±10N·m(41±7lbft)

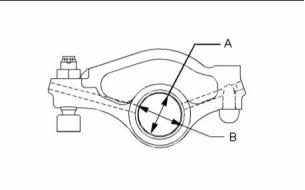

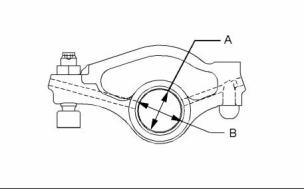

i02796844

ElectronicUnitInjectorRocker

Arm

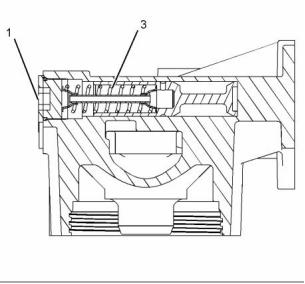

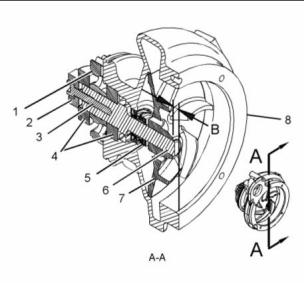

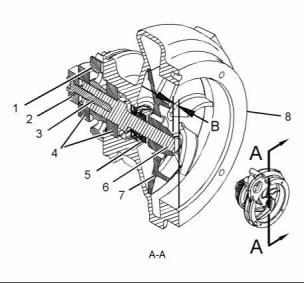

g01364153

Illustration 8

g01363845

Illustration 9

(1) Electronic unit injector

(2) Locknut

(A) Bearingborediameter......... 34.050±0.015mm

(1.3405 ±0.0006 inch)

(3) Electronic unit injector rocker arm

(4) Rocker arm shaft

(5) Lifter group shaft

(6) Electronic unit injector lifter

(B) Bore in the rocker arm for the

bearing................................. 37.000±0.020mm

(1.4567 ±0.0008 inch)

Procedure forsettingtheunitinjector assembly

1. Setnumber 1piston atTDCofthecompression

Note: The rocker arm bearing must not extend

stroke

beyond eitherfaceoftherocker arm.

2. Setunitinjectors oncylinder 3,5,and6.

3. Turnthecrankshaft 360degrees indirection of

engine rotation (number 6piston atTDCofthe

compression stroke).

4. Setunitinjectors oncylinder 1,2,and4.

The adjusting instructions fortheunit injector are

listed below.

1. Loosen thelocknut (2).

This document is printed from SPI². Not for RESALE

![]()

![]()

8

Specifications Section

KENR6905

i02796846

ElectronicUnitInjectorWiring

g01072563

Illustration 10

(1) Wiring harness connectors

(2) Torqueforthecapnuts................ 2.5±0.25N·m

(22 ±2lbin)

This document is printed from SPI². Not for RESALE

![]()

KENR6905

9

Specifications Section

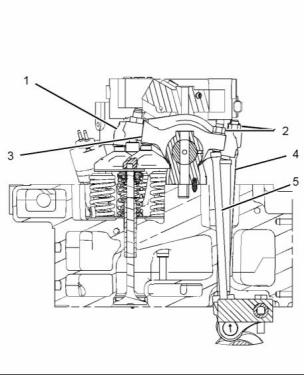

i02797205

Valvelashsetting....................... 0.38±0.08mm

(0.015 ±0.003 inch)

Tightenjamnut(2)aftersettingthevalvelashto

thefollowing torque. .......................... 30±7N·m

(20 ±5lbft)

ValveMechanism

(4) Pushrod fortheexhaust valve

(5) Pushrod fortheInletvalve

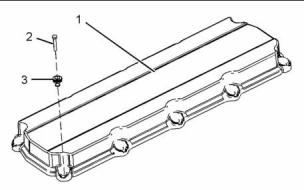

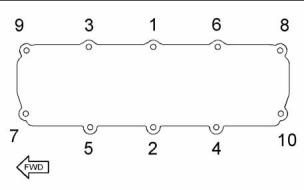

i02797212

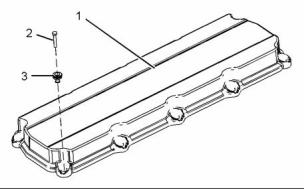

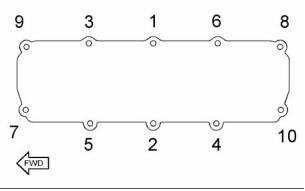

ValveMechanismCover

g01445055

Illustration 12

g01363806

Illustration 11

Procedure forsetting thevalvelash

1. Setnumber 1piston atTDCofthecompression

stroke

a. Setinletvalves oncylinder 1,2,and4

b. Setexhaust valvesoncylinders 1,3,and5

2. Turnthecrankshaft 360degrees indirection of

engine rotation (number 6piston atTDCofthe

compression stroke).

g01380900

Illustration 13

a. Setinletvalves oncylinder 3,5,and6

b. Setexhaust valvesoncylinders 2,4,and6

(1) Exhaust rocker arm

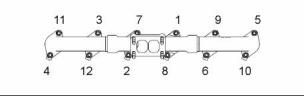

RefertoIllustration 13forthetightening sequence

ofthevalve cover bolts.

(1) Valvemechanism cover

(2) Bolts

Valvelashsetting ...................... 0.64±0.08mm

(0.025 ±0.003 inch)

Tightenthejamnut(2)aftersettingthevalvelash

tothefollowing torque. ...................... 30±7N·m

(20 ±5lb ft)

Torqueforbolts......................... 28N·m(21lbft)

(3) Isolators

(3) Inlet rocker arm

This document is printed from SPI². Not for RESALE

![]()

![]()

10

Specifications Section

KENR6905

i02796322

(B)Valvestemdiameter ........ 9.441±0.008mm

(0.3717 ±0.0003 inch)

CylinderHeadValves

Minimum valvestemdiameter ............ 9.309mm

(0.3665 inch)

(C)Diameter ofvalvehead...... 44.50±0.13mm

(1.752 ±0.005 inch)

(D)Valvefaceangle ......... 60.75±0.25degrees

(E)Minimumvalvelipthickness ..3.50±0.20mm

(0.138 ±0.008 inch)

(2) Spring

Assembled length ........... 50.47mm(1.987inch)

Loadatassembled length ................. 160±13N

(36 ±3lb)

Minimum operating length .................. 34.92mm

(1.375 inch)

Loadatminimum operating length ....385±18N

(87 ±4lb)

Outsidediameter ............ 23.24mm(0.915inch)

Freelengthaftertest .......... 64.1mm(2.52inch)

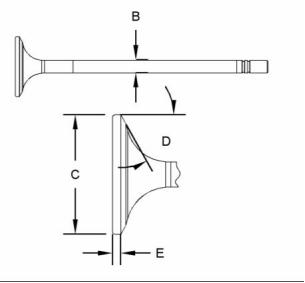

g01352702

Illustration 14

g01352701

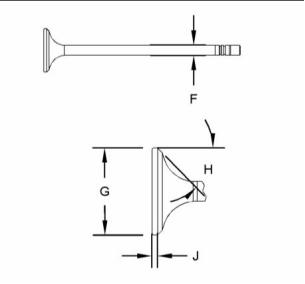

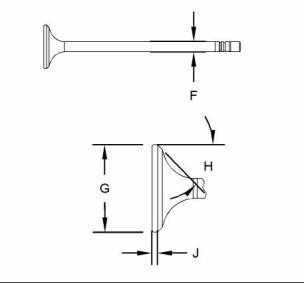

Illustration 16

Exhaust valve

(3) Exhaust valve

(F)Valvestemdiameter ........ 9.441±0.008mm

(0.3717 ±0.0003 inch)

Minimum valvestemdiameter ............ 9.309mm

(0.3665 inch)

g01352699

Illustration 15

Inlet valve

(G)Diameter ofvalvehead ..... 41.50±0.13mm

(1.634 ±0.005 inch)

Note: Apply engine oiltothevalve stems prior to

(H)Valvefaceangle ......... 45.75±0.25degrees

(J)Minimumvalvelipthickness ..3.50±0.20mm

(0.138 ±0.008 inch)

installation inthecylinder head.

(A) Height to the step in the valve

guide............... 22.0±0.5mm(0.87±0.02inch)

(4) Spring

Assembled length ........... 52.95mm(2.085inch)

(1) Inlet valve

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR6905

11

Specifications Section

Loadatassembled length .................320±31N

(72 ±7lb)

Minimum operating length .................. 37.40mm

(1.472 inch)

Loadatminimum operating length ....860±34N

(195 ±7.6 lb)

Outside diameter ............ 34.00mm(1.339inch)

Freelengthaftertest .......... 62.7mm(2.47inch)

(5) Valveguide

Boreofinstalled valveguide.. 9.508±0.013mm

(0.3743 ±0.0005 inch)

Maximum recommended diameter ofthevalve

guidebore..................... 9.544mm(0.3757inch)

Note: Do not use acombination ofavalve and

a valve guide that has adifference of 0.13 mm

(0.005 inch) ormore.

(6) Inlet valve seat

Angleofvalveseat ........... 60.25±0.25degrees

Diameter ofvalveseat......... 45.525±0.013mm

(1.7923 ±0.0005 inch)

Bore in cylinder head for valve

seat.. 45.461±0.015mm(1.7898±0.0006inch)

(7) Exhaust valve seat

Angleofvalveseat ........... 44.75±0.25degrees

Diameter ofvalveseat......... 42.390±0.015mm

(1.6689 ±0.0006 inch)

Bore in cylinder head for valve

seat.. 42.320±0.015mm(1.6661±0.0006inch)

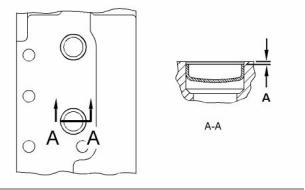

i02796321

CylinderHead

Table2

Required Tools

Tool

Part Number

Partdescription

A

CV60895

POWERPART

Special

Lubricant

ApplyTooling(A)totheboltthreads andbothsides

ofthewashers.

This document is printed from SPI². Not for RESALE

![]()

12

Specifications Section

KENR6905

g01400360

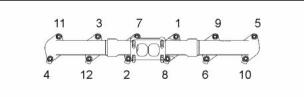

Illustration 17

1. Tightenbolt(1)through bolt(26)inanumerical

Rotate the bolts in the clockwise

direction. ..................... 120±5degrees (1/3turn)

sequence.

Tighten the bolts to the following

torque. .......................170±10N·m(125±7lbft)

8. Tightenbolt(27)through bolt(33)inanumerical

sequence.

2. Tighten bolt (1) through bolt (26) again in a

Tighten the bolts to the following

torque................................................ 55±10N·m

(41 ±7lbft)

numerical sequence.

Tighten the bolts again to the following

torque. ............................................. 170±10N·m

(125 ±7lb ft)

3. Placeamarkonbolt(1)through bolt(26).Rotate

bolt(1)through bolt(26)inanumerical sequence.

Rotate the bolts in the clockwise

direction. ..................... 120±5degrees (1/3turn)

4. Loosen bolt (1) through bolt (26) until the

washers arelooseundertheboltheads.

5. Tightenbolt(1)through bolt(26)inanumerical

sequence.

g01352102

Illustration 18

Tighten the bolts to the following

torque. ............................................. 170±10N·m

(125 ±7lb ft)

(A) The cup plugs are measured from the head

face to the top edge of the plug. Depth of

installation.................................. 1.25±0.25mm

(0.049 ±0.010 inch)

6. Tighten bolt (1) through bolt (26) again in a

numerical sequence.

Minimum permissible thickness of cylinder

head........................................................ 164.85mm

(6.4901 inch)

Tighten the bolts again to the following

torque. ............................................. 170±10N·m

(125 ±7lb ft)

Maximum permissible thickness of cylinder

head........................................................ 165.15mm

(6.502 inch)

7. Placeamarkonbolt(1)through bolt(26).Rotate

bolt(1)through bolt(26)inanumerical sequence.

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR6905

13

Specifications Section

Note: The flatness of the cylinder

head should be within 0.15 mm

(0.006 inch). The flatness should also be a

maximumof0.05mm(0.002inch)forany150.00mm

(5.906 inch) span.

i02796858

ExhaustManifold

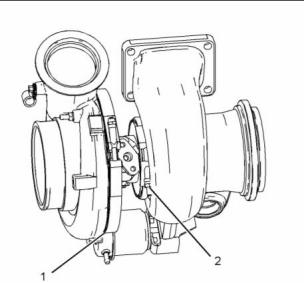

i02797171

Turbocharger

g01332495

Illustration 20

Typical example ofanexhaust manifold with aflange with three

studs

(1) Exhaust manifold Gasket

(2) Spacer

(3) Washer

g01350326

Illustration 19

(4) Apply CV60889 Anti-Seize Compound tothe

studthreads. Tightenthestuds tothefollowing

torque. ........................... 35±5N·m(26±4lbft)

Typical example

(1) TorquefortheV-bandclamp .......13.5±1.0N·m

(120 ±9lbin)

(5) Apply CV60889 Anti-Seize Compound tothe

studthreads. Tightenthestuds tothefollowing

torque. ........................... 35±5N·m(26±4lbft)

(2) V-band clamp

1. TightentheV-band clamp.

Note:Theexhaust manifold gaskets havetabs.The

tabsshould point totheoilpan.

Torque................................... 18.1N·m(160lbin)

2. Loosen theV-band clamp.

Torque....................................... 5.6N·m(50lbin)

3. Again, tighten theV-band clamp.

Torque.................... 13.5±1.0N·m(120±9lbin)

g01329313

Illustration 21

Tightening sequence (typical example)

Tightenthenutsinthenumerical sequence thatis

shown inIllustration 21.

This document is printed from SPI². Not for RESALE

![]()

![]()

14

Specifications Section

KENR6905

i02796856

i02796233

ExhaustElbow

Camshaft

g01290855

g01071831

Illustration 22

Illustration 23

Typical example

Typical example

(1) Tighten the nutforthe clamp tothe following

torque. ...................................... 14N·m(10lbft)

(1) Diameter of camshaft bearing

journal ... 77.850±0.025mm(3.0650 ±0.0010inch)

The lobe on the camshaft for the injector has

the most liftwhen the cam isatzero degrees of

rotation. ............................. 12.703mm(0.5001inch)

The lobe on the camshaft for the

injector has zero lift through the given

rotation. .......................... 74degrees to254degrees

Whentheinjector lobehasaliftheight of5.238mm

(0.2062 inch),thecamshaft shouldhaveanangleof

rotation. ...................................... 35±0.038degrees

The lobe on the camshaft for the inlet has the

most lift when the cam is at zero degrees of

rotation. ............................. 12.607mm(0.4963inch)

The lobe on the camshaft for the

inlet has zero lift through the given

rotation. .......................... 78degrees to284degrees

When theinlet lobe hasaliftheight of5.135 mm

(0.2022 inch),thecamshaft shouldhaveanangleof

rotation. .......................................... 32±0.2degrees

The lobe on the camshaft for the exhaust has

the most liftwhen the cam isatzero degrees of

rotation. ............................... 9.417mm(0.3707inch)

This document is printed from SPI². Not for RESALE

![]()

KENR6905

15

Specifications Section

The lobe on the camshaft for the

exhaust has zero lift through the given

rotation. .......................... 82degrees to279degrees

Whentheexhaust lobehasaliftheightof5.279mm

(0.2078 inch),thecamshaft should haveanangleof

rotation. .......................................... 32±0.2degrees

i02796849

EngineOilFilterBase

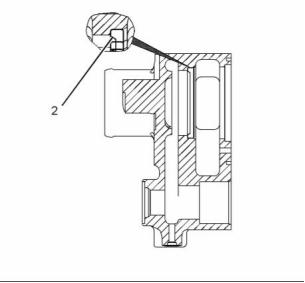

g01525668

Illustration 26

Section A-A

Oil cooler bypass

Pressure difference foropening theoilfilterbypass

valveandoilcoolerbypassvalve ........ 255±20kPa

(37 ±3psi)

(1) Torquefortheplugs ..100±15N·m(75±11lbft)

(2) Spring

Assembled length ........... 55.25mm(2.175inch)

Loadatassembled length ..................... 75±6N

(17.0 ±1.3 lb)

Freelengthaftertest .......... 93.7mm(3.69inch)

Outsidediameter ................ 20.6mm(0.81inch)

g01525662

Illustration 24

Right Side View

g01525673

g01525663

Illustration 27

Illustration 25

View D-D

Section B-B

Pump bypass valve

Oil filter bypass

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

16

Specifications Section

KENR6905

Fullopenpressure .............. 374.70kPa(54.346psi)

(3) Spring

i02796855

EngineOilPump

Assembled length ........... 96.52mm(3.800inch)

Loadatassembled length .......... 92.52N(21lb)

Freelengthaftertest .... 124.71mm(4.910inch)

Outsidediameter ............ 21.84mm(0.860inch)

g01330627

Illustration 29

g01525684

Typical example

Illustration 28

Section C-C

NOTICE

High pressure relief valve

Before operating the engine, the oil pump must be

lubricated with clean engine oil. The oil pump must

turn freely by hand. Damage to the drive gear and

internalpumpdamagecanoccuriftheoilpumpisnot

lubricated withclean engine oil.

Reliefpressure.................... 679.77kPa(98.594psi)

(4) Retainer Spring

Assembled length ........... 21.44mm(0.844inch)

Loadatassembled length ..............200±15.5N

(45.0 ±3.5 lb)

Freelengthaftertest ...... 30.96mm(1.219inch)

Outside diameter ............ 19.66mm(0.774inch)

Engine oilpump

Oiltype ................................................... SAE30

Oiltemperature ............................ 50°C(122°F)

Pumpspeed ........................................ 3000rpm

Oilpressure .............................. 359kPa(52psi)

Minimum oilflow ............ 185L/min(49USgpm)

(1) Pump gears

Inordertoinstallthepumpgears,heatthepump

gearstothefollowing temperature. ......... 316°C

(601 °F)

Lengthofnewgears ............ 50.000±0.025mm

(1.9685 ±0.0010 inch)

Depth of bores in oil pump body for the

gears....... 50.13±0.02mm(1.974±0.001inch)

(2) Oilpump shaftassembly

Diameter oftwoshafts......... 18.000±0.005mm

(0.7087 ±0.0002 inch)

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

KENR6905

17

Specifications Section

Bores in oil pump body for two

shafts ................................... 18.050±0.010mm

(0.7106 ±0.0004 inch)

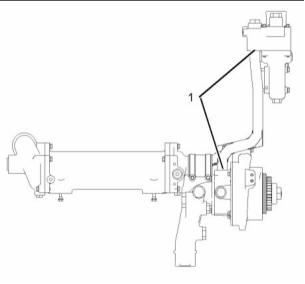

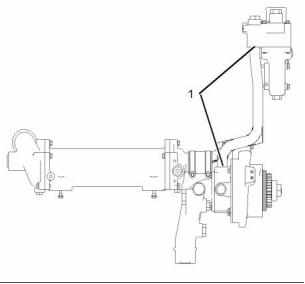

i02797220

WaterLines

(3) Inordertoinstalltheoilpumpdrivegear,heatthe

geartothefollowing temperature. ........... 316°C

(601 °F)

(4) Seal groove

(5) O-ring seal

i02796850

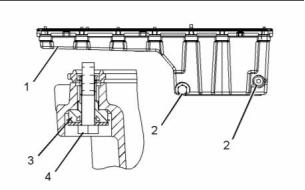

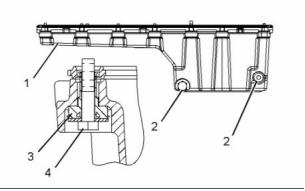

EngineOilPan

g01530614

Illustration 31

Typical example

(1) Seal bores

Applyalightcoatofglycerintothesealbores.

g01098480

Illustration 30

Front sump

(1) Oil pan

(2) Torqueforplugs............................... 70±15N·m

(52±11lb ft)

(3) Rubber grommet

(4) Oil pan bolt

This document is printed from SPI². Not for RESALE

![]()

18

Specifications Section

KENR6905

i03001200

i02797230

WaterTemperatureRegulator

WaterTemperatureRegulator

Housing

g00285471

Illustration 34

Typical example

Completely opentemperature ........... 98°C(208°F)

Minimum opening distance at 98 °C

(208°F)..................................... 10.4mm(0.41inch)

g01074249

Illustration 32

g01521205

Illustration 33

Section A-A

Note: Lightly lubricate thesealing lipoftheliptype

seal with glycerin.

The lip type seal (2) is installed in the water

temperature regulator housing (1).Thisisshown in

Illustration 33.

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR6905

19

Specifications Section

i02797224

WaterPump

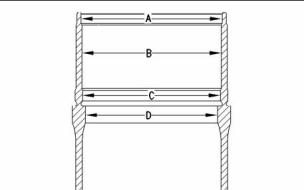

g00488509

Illustration 36

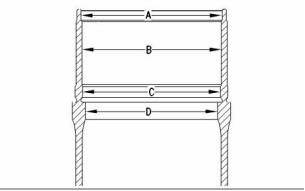

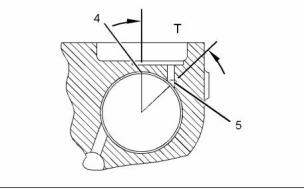

Borediameters inthecylinder blockforthecylinder

block liners:

(A)......... 151.50±0.03mm(5.965±0.001inch)

(B)......... 149.80±0.30mm(5.898±0.012inch)

(C)......... 148.00±0.03mm(5.827±0.001inch)

(D)......... 141.90±0.05mm(5.587±0.002inch)

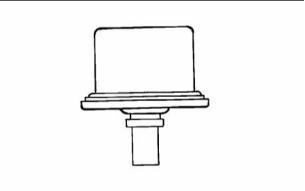

g01329370

Illustration 35

(1) Gear

(2) Washer

(3) Bolt

(4) Ball bearings

(5) Seal group

(6) Water pump shaft

(7) Impeller

(8) Pump housing

The cup plug can be recessed to the following

distance. ................................. 1.25mm(0.049inch)

(B) Thedistance between thepumpflange andthe

impeller hub .............................. 8.40±0.25mm

(0.331 ±0.010 inch)

i02796319

CylinderBlock

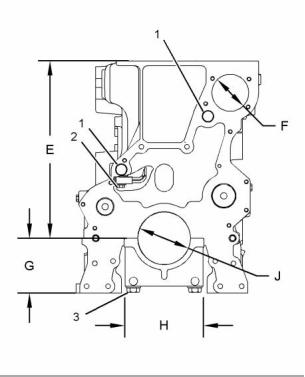

g01352212

Theflatness ofthetopcontactsurface ofthecylinder

block must bewithin 0.05mm(0.002 inch) forany

150mm(5.9inch)section ofthesurface.

Illustration 37

Front View

(2) Bolts forthe piston cooling jets

(E) Distance fromthecenterline ofthecrankshaft

bore to the top surface of the cylinder

block ........................... 387.00mm(15.236inch)

(F) Diameter of the camshaft

bores.................................... 85.000±0.015mm

(3.3464 ±0.0006 inch)

This document is printed from SPI². Not for RESALE

![]()

![]()

20

Specifications Section

KENR6905

(G) Distance from thecenterline ofthecrankshaft

to the bottom surface of the cylinder

block ................................. 120.0mm(4.72inch)

Width in cylinder block for the main bearing

cap ...... 178.000 ±0.023mm(7.0079±0.0009inch)

(H) Width of the main bearing

cap..................................... 178.000 ±0.020mm

(7.0079 ±0.0008 inch)

(J) Bore inthe cylinder block for theseven main

bearings .............................. 116.000±0.013mm

(4.5669 ±0.0005 inch)

g01352291

(1) Apply6V-6640 Sealant totheboresofthecup

Illustration 38

plugs.

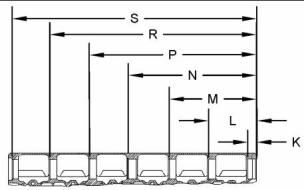

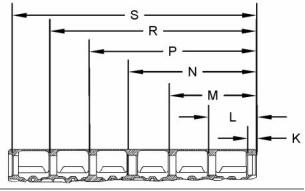

Thecamshaft bearings areinstalled intothecylinder

block atthevalues thatfollow.

(3) Main bearing capbolts

(K)................................... 36.50mm(1.437inch)

(L) ................................. 192.50mm(7.579inch)

(M) .............................. 348.50mm(13.720inch)

(N)............................... 504.50mm(19.862 inch)

(P)............................... 660.50mm(26.004inch)

(R)............................... 816.50mm(32.145 inch)

(S)............................... 972.50mm(38.287inch)

Use thefollowing procedure inorder toinstall the

main bearing capbolts:

1. Orient themainbearing cap correctly.The part

number onthemainbearing capmustfacetothe

right andtothefrontfaceoftheblock. Also, the

tabslotsthatareintheblockandthemainbearing

caps must beadjacent.

NOTICE

Camshaftbearingsmustbeinstalledintotheircorrect

position.Failuretodosowillresultinenginedamage.

Note: The main bearing caps are marked with

identification numbers 1through 7.Installthemain

bearing capsintothecorrect positions.

2. Lubricate themain bearing capbolts. UseSAE

30W oilormolybdenum grease tolubricate the

threads andthewasher face.

3. Tightenthemainbearing capbolts.

Tightenboltstothefollowing torque. ..50±5N·m

(37 ±4lb ft)

4. Putanalignment markoneachcapandbolt.

Rotate theboltsintheclockwise direction bythe

following angle. ............................ 90±5degrees

g01352353

Illustration 39

(4) Bearing joint

(5) Oil hole

(T) Bearing oilholeislocated atthefollowing angle

fromthevertical.Allthesevenbearings havethe

sameangle. ...................................... 45degrees

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

KENR6905

21

Specifications Section

i02796327

i02796281

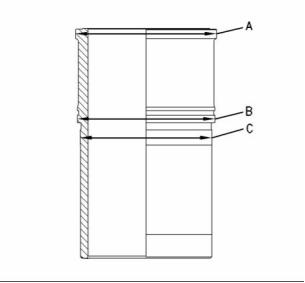

CylinderLiner

Crankshaft

Table3

Required Tools

Tool

Part Number

Partdescription

A

21820221

POWERPART

Rubber Grease

g01447590

Illustration 41

(1) Main bearing journals

(2) Connecting rodbearing journals

Thethrustplate should beusedonlyonthecenter

main bearing journals.

(A) Dimensions forcrankshaft gear

g00517737

Illustration 40

Average diameter after

Outside diameters ofthecylinder liner

assembly ................................ 136.20±0.11mm

(5.362 ±0.004 inch)

Note: Apply Tooling(A) tothecylinder linerseals

Maximum diameter afterassembly... 136.36mm

(5.368 inch)

prior toassembly.

Table4

(C) Heightfromtopofthedoweltothesurfaceofthe

crankshaft ......... 8.0±0.5mm(0.31±0.02inch)

Position A

Position B

Position C

151.42 ±0.05mm(5.961 ±0.002 inch)

147.90 ±0.03mm(5.823± 0.001 inch)

141.38 ±0.08mm(5.566 ±0.003 inch)

Note:Thegapbetween thecrankshaft gearandthe

crankshaft shouldnotexceed0.10mm(0.004inch).

InnerBore

Diameter

130.025±0.025mm(5.1191±0.0010inch)

This document is printed from SPI². Not for RESALE

![]()

![]()

22

Specifications Section

KENR6905

i02796303

CrankshaftSeals

g01331026

Illustration 43

Note: Usethealternating sequence thatisshown

whentightening thefrontandrearsealbolts.

i02797214

VibrationDamper

g01332511

Table5

Illustration 42

(1) Crankshaft seal

(3) Crankshaft

Required Tools

Part Number

Tool

Part Description

Note: Installthefrontcrankshaft seals andtherear

A

CV60889

Anti-Seize

Compound

crankshaft seals dry.

(2) O-ringseal ............ Lightlylubricate thesealwith

thelubricant thatisbeing sealed.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

KENR6905

23

Specifications Section

i02797145

MainBearingJournal

Table7

Main Bearing Journal

Original sizejournal

108.000 ±0.020 mm

(4.2520 ±.0008 inch)

Undersize journal

0.510 mm(.0201 inch)

107.490 ± 0.020 mm

(4.2320 ±.0008 inch)

Undersize journal

0.760 mm(.0300 inch)

107.240 ±0.020 mm

(4.2220 ±.0008 inch)

Theclearance between anewbearing andanew

journalisthefollowing value....... 0.081to0.181mm

(.0032 to.0071 inch)

g01288983

Illustration 44

Table8

(1) Adapter

Main Bearing Bore

(2) Damper

Mainbearing bore(original

size)

116.000 ± 0.013 mm

(4.5669 ±.0005 inch)

(3) Tighten the bolts to the following

torque. .................................... 105N·m(77lbft)

Oversize bore inblock

0.510 mm(.0201 inch)

116.510 ± 0.013 mm

(4.5870 ±.0005 inch)

(4) ApplyTooling(A)totheboltsandtightenthebolts

tothefollowing torque. ......... 270N·m(200lbft)

i02796273

Connecting Rod Bearing

Journal

Table6

Connecting Rod Bearing Journal

Original sizejournal

89.000 ± 0.020 mm

(3.5039 ±.0008 inch)

Undersize journal

0.508 mm(.0200 inch)

88.492 ± 0.020 mm

(3.4839 ±.0008 inch)

Undersize journal

0.762 mm(.0300 inch)

87.238 ± 0.020 mm

(3.4346 ±.0008 inch)

The clearance between anew bearing andanew

journalisthefollowing value....... 0.062to0.132mm

(.0024 to.0052 inch)

This document is printed from SPI². Not for RESALE

![]()

24

Specifications Section

KENR6905

i02796261

Bore inthe connecting rod for the piston pin

bearing................................. 57.810±0.013mm

(2.2759 ±0.0005 inch)

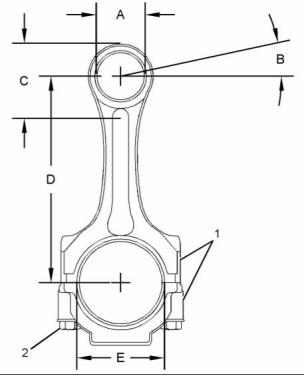

ConnectingRod

Bore in the bearing for the piston

pin... 53.205±0.008mm(2.0947 ±0.0003inch)

Diameter ofthepistonpin.... 53.155±0.005mm

(2.0927 ±0.0002 inch)

(B) Location ofthebearing jointfromthehorizontal

centerline ofthepinbore ......... 12.5±5degrees

Note: The connecting rodmust beheated forthe

installation ofthepiston pinbearing. Donotusea

torch.

(C) The connecting rod may be heated from

175 °C to260 °C (347 °F to 500 °F) for the

installation ofthepiston pinbearing. Maximum

distance forheating theconnecting rod... 88mm

(3.5 inch)

(D) Distance between the center of the

bearings ................................. 239mm(9.4inch)

(E) Bore intheconnecting rodforthe crankshaft

bearing................................. 93.800±0.013mm

(3.6929 ±0.0005 inch)

i02797157

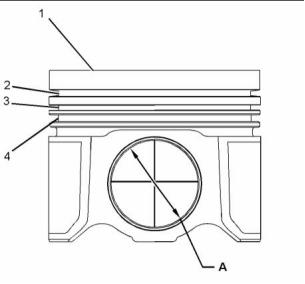

PistonandRings

g01507769

Illustration 45

(1) Etchthecylinder number ontheconnecting rod

andthecapinthislocation. Marktheconnecting

rodandthecapwithanumber 1through 6.Mark

thenumbers onthesamesideoftheconnecting

rodasthebearing retainer notch.

Note:Installtheconnecting rodintheenginewiththe

partnumber totherearoftheengine.

Usethefollowingprocedure totightentheconnecting

rod bolts (2):

1. Tightentheconnecting rodboltsto130±7N·m

(95 ±5lbft).

2. Rotateeachconnecting rodboltsforanadditional

60±5degrees.

Note: Thoroughly lubricate the piston pin with

cleanengine oilpriortoassembly ofthepiston and

connecting rod.

g01324733

Illustration 46

(A) Dimensions forthepiston pin

(1) Thepistonissymmetrical withacentercrater.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

KENR6905

25

Specifications Section

Lubricate theentirepistonto360°inzone(A)priorto

assembly intothecylinder block. Useclean engine

oil.

Thoroughly lubricate thepistonpinwithcleanengine

oilprior toassembly.

(2) Toppiston ringgroove

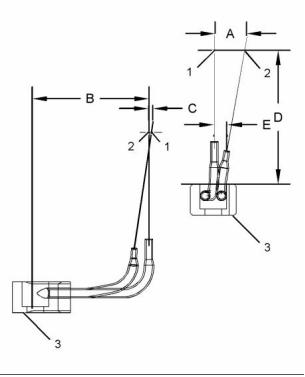

i02973664

PistonCoolingJet

Installthepistonringwiththesidemarked“UP-1”

toward thetopofthepiston.

The ends ofthepiston ring have aclearance

when the piston ring isinstalled inacylinder

linerwithaboreof130.000 mm(5.1181inch).

Clearance ..0.40±0.05mm(0.016±0.002inch)

Thetoppistonringhasanincrease inclearance

foreach 0.03mm(0.001 inch) increase inthe

cylinderlinerbore.Increase ................. 0.09mm

(0.004 inch)

(3) Intermediate piston ringgroove

Installthepistonringwiththesidemarked“UP-2”

toward thetopofthepiston.

Width ofgroove innewpiston forintermediate

pistonring .............................. 3.053±0.013mm

(0.1202 ±0.0005 inch)

Thickness of new intermediate piston

ring...........2.98±0.01mm(0.117±0.0004inch)

The ends ofthepiston ring have aclearance

when the piston ring isinstalled inacylinder

linerwithaboreof130.000 mm(5.1181inch).

Clearance ....... 0.8±0.1mm(0.03±0.004inch)

Theintermediate piston ringhasanincrease in

clearanceforeach0.03mm(0.001inch)increase

inthecylinder linerbore.Increase........ 0.09mm

(0.004 inch)

(4) Oilcontrol ringgroove

Theendsoftheoilcontrol pistonringshould be

adistance of180degrees fromtheringendgap

whentheoilcontrolpistonringisassembled. The

whitecolored portion ofthepiston ringmustbe

visible attheringendgap.

g01502131

Illustration 47

Thepiston cooling jets(3)mustbechecked forthe

location ofthestream ofoil.Insert adrillrodwitha

diameter of2.0mm(0.08inch) intotheorifice. This

drill rodsimulates thestream ofoilunder normal

operating pressure. Thedrillrodmustpassthrough

acircle withadiameter of10.0mm(0.40 inch) at

point(2).Placethedrillrodinthesecondorifice. , ; The

drillrodmustpassthrough acircle withadiameter

of10.0mm(0.40inch)atpoint (1).Thecircles are

located atdimension (D).

Widthofgrooveinnewpistonforoilcontrolpiston

ring......................................... 4.052±0.012mm

(0.1595 ±0.0005 inch)

Thickness of new oil control piston

ring.... 3.980±0.010mm(0.1567 ±0.0004inch)

The ends ofthepiston ring have aclearance

when the piston ring isinstalled inacylinder

linerwithaboreof130.000 mm(5.1181inch).

Clearance ..0.45±0.15mm(0.018±0.006inch)

The oil control piston ring has anincrease in

clearanceforeach0.03mm(0.001inch)increase

inthecylinder linerbore.Increase........ 0.09mm

(0.004 inch)

Usethefollowing dimensions inordertolocatepoint

(1)and point (2).

Dimension (A).......................... 47.10±0.25mm

(1.854 ±0.010 inch)

Dimension (B).......................... 55.30±0.25mm

(2.177 ±0.010 inch)

Afterthepistonringshavebeeninstalled, rotatethe

piston rings sothattheendgapsare120degrees

from each other.

Dimension (C)............................ 3.84±0.25mm

(0.151 ±0.010 inch)

Dimension (D)........................ 250.00±0.25mm

(9.842 ±0.010 inch)

(A) Pistonpinborediameter ......... 53.25±0.01mm

(2.0965 ±0.0004 inch)

Dimension (E)................... 4.50mm(0.177inch)

This document is printed from SPI². Not for RESALE

![]()

![]()

26

Specifications Section

KENR6905

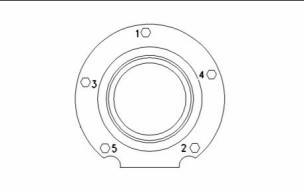

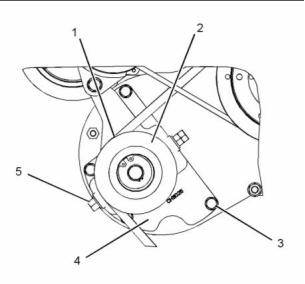

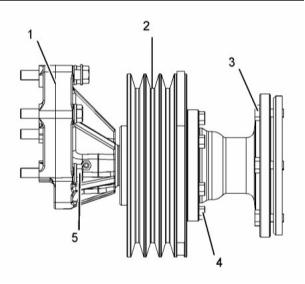

i02797047

(5) Accessory driveassembly

Housing(Front)

g01190314

Illustration 48

g00952129

Illustration 49

Tightening sequence forthefront crankshaft seal

(1) Self-locking boltM8-1.25

(2) Seventeen boltsfastenthecovertothehousing.

Note:Bolt(1)isdifferentfromtheothercoverbolts.

(3) Nineboltsfastenthehousing totheblock.

(4) O-ring sealandcrankshaft frontseal

TheO-ringsealandthecrankshaft frontsealarepart

ofthefronthousing. Lubricate theO-ringseallightly.

Usethelubricant thatisbeingsealed.

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR6905

27

Specifications Section

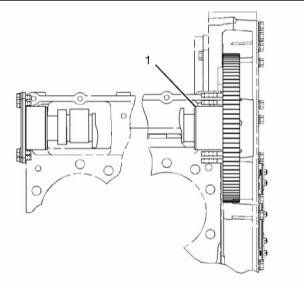

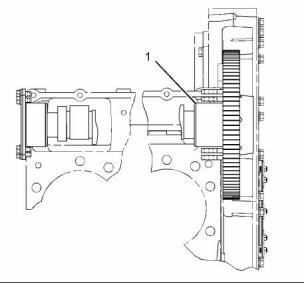

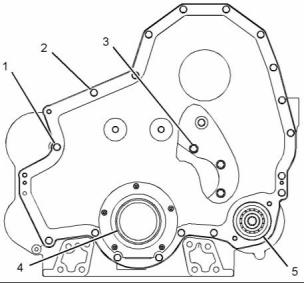

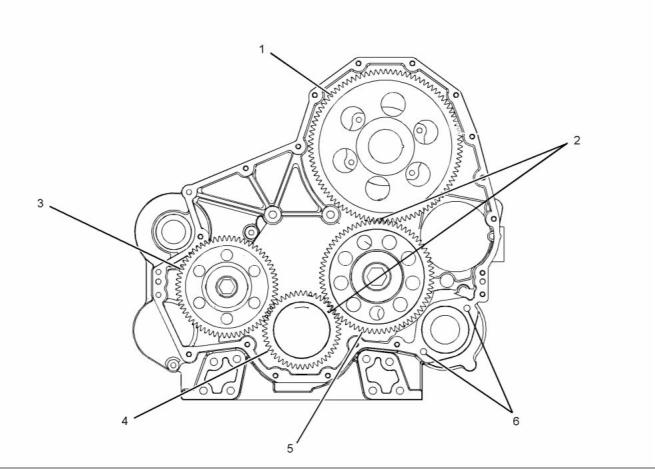

i02797043

GearGroup(Front)

g01098608

Illustration 50

(6)Tappedholes foraccessory drive

(1) Camshaft gear

(4) Crankshaft gear

Numberofteeth.............................................. 96

Borediameter ...................... 58.900±0.013mm

(2.3189 ±0.0005 inch)

Number ofteeth.............................................. 48

Borediameter .......................... 96.90±0.02mm

(3.815 ±0.001 inch)

(2) Align thetiming marks ontheidler gear tothe

timingmarksonthecamshaftgearandthemarks

onthecrankshaft gear.

(5) Idler gear

Number ofteeth.............................................. 71

Borediameter forbearing .... 74.452±0.015mm

(2.9312 ±0.0006 inch)

(3) Idlergearforthewater pump

Bore diameter of the

Numberofteeth.............................................. 64

Borediameter forbearing.... 60.163±0.015mm

(2.3686 ±0.0006 inch)

bearing................................. 68.780±0.193mm

(2.7079 ±0.0076 inch)

Bore diameter of the

bearing................................. 55.281±0.039mm

(2.1764 ±0.0015 inch)

This document is printed from SPI². Not for RESALE

![]()

![]()

28

Specifications Section

KENR6905

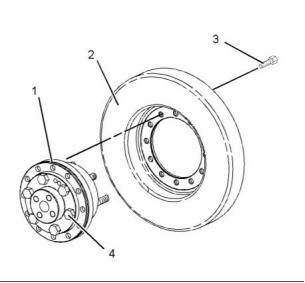

i02796863

Flywheel

g01525652

Illustration 52

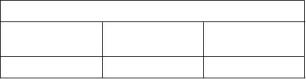

Apply asmall amount ofTooling(A)onthegasket

surface of the flywheel housing. Assemble the

flywheel housing tothecylinder block and tighten

withintenminutes ofapplying thesealant.

g01071339

Illustration 51

i02796865

Note: Refer to System Operation, Testingand

Adjusting forthecorrect method ofinspecting the

flywheel.

FlywheelHousingCover

(1) Bolt

(2) Ring gear

(1) Tightenthe bolts thathold the flywheel tothe

crankshaft.

Tighten the bolts to the following

torque........................... 300±40N·m(220±30lbft)

i02796864

FlywheelHousing

Table9

Required Tools

Tool

PartNumber

Part

Description

g01072994

Illustration 53

A

CH10879

Liquid Gasket

(1) Bolt

This document is printed from SPI². Not for RESALE

![]()

![]()

KENR6905

29

Specifications Section

Tighten the three bolts on the cover to the

following torque. ....................... 48N·m(35lbft)

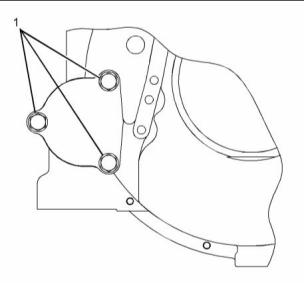

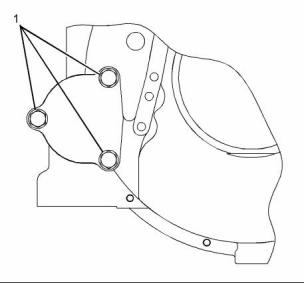

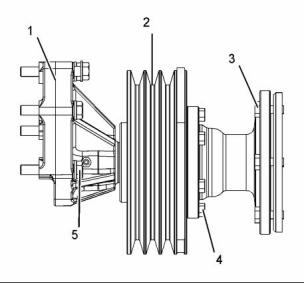

i02796859

FanDrive

i02796227

BeltTightener

g01525682

Illustration 55

(1) Fandrive assembly

(2) Pulley

g01525651

Illustration 54

Typical example

(3) Tighten the bolts to the following torque.

.................................................. 47N·m(35lbft)

(1) Nut

Tightenthenuttothefollowingtorque. ..102N·m

(75 lb ft)

(4) TightentheBoltstothefollowingtorque. ..47N·m

(35 lb ft)

(2) Pulley

(3) Bolt

(5) Tighten the Bolts to the following

torque. .................................... 105N·m(77lbft)

Tightenthenuttothefollowing torque.....47N·m

(35 lb ft)

Note: Rotate bolt(3)inorder toadjust thetension

oftheV-belts. Refer toOperation andMaintenance

Manual, “Belts -Inspect/Adjust/Replace” formore

information.

(4) Belt Tightener

(5) TensionBolt

This document is printed from SPI². Not for RESALE

![]()

![]()

30

Specifications Section

KENR6905

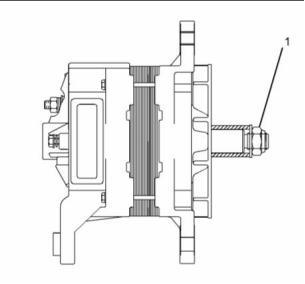

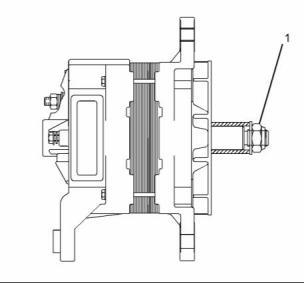

i02796212

Minimum fullloadcurrentat2000rpm ......... 35Amp

Turnonspeed............................................ 2300rpm

Outputvoltage ....................................... 27.5±0.3V

(1) Pulleynut.....................102±7N·m(75±5lbft)

AlternatorandRegulator

(2) Positive batteryterminal .............. 11.3±2.3N·m

(100 ±20lbin)

(3) Negative batteryterminal...............6.2±0.6N·m

(55±5lb in)

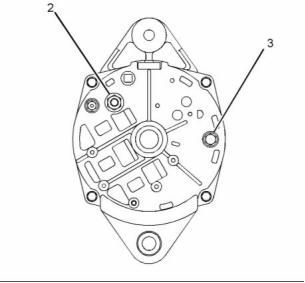

i02796840

ElectricStartingMotor

g01074003

Illustration 56

g01525644

Illustration 58

g01074005

Illustration 57

Voltage............................................................... 24V

Amperage ..................................................... 70Amp

Polarity ............................................ Negative ground

Rotation ............................................ Eitherdirection

Minimum fullloadcurrentat5000rpm ......... 75Amp

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

KENR6905

31

Specifications Section

(6) Motor terminal

Tighten the nut onthe battery terminal tothe

following torque. ......30.5±3.5N·m(22±3lbft)

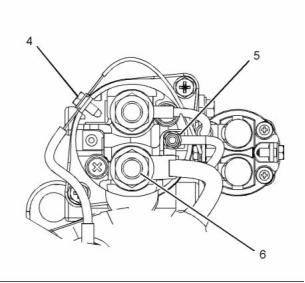

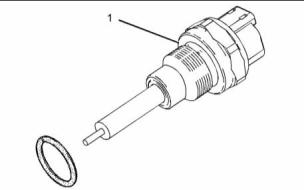

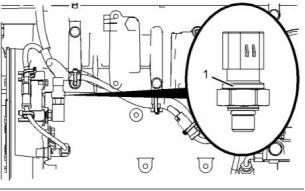

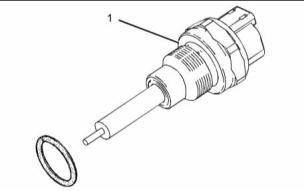

i02796276

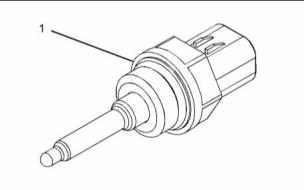

CoolantTemperatureSensor

g01525646

Illustration 59

When the electric starting motor isviewed from

the drive end, the motor rotates in the following

direction. ................................................... Clockwise

g01291117

Illustration 60

Noloadconditions at25°C(77°F)

Typical example

Minimum speed ..................................... 106rpm

Maximum output ...................................... 7.8kW

Voltage......................................................... 24V

(1) Sensor assembly

Tighten the sensor assembly tothe following

torque. ..................................................... 20N·m

(15 lb ft)

(1) Ground terminal

Tighten thenut on thebattery terminal tothe

following torque. ......30.5±3.5N·m(22±3lbft)

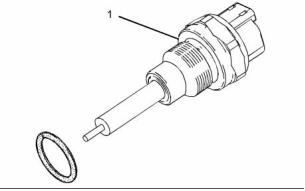

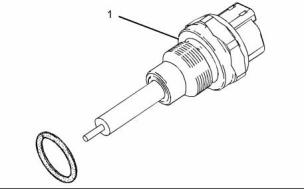

i02797035

FuelTemperatureSensor

(2) Battery terminal

Maximum number ofcable or wire terminals

between thenuts .............................................. 3

Tighten thenut on thebattery terminal tothe

following torque. ......30.5±3.5N·m(22±3lbft)

(3) Starter relay terminal

Tighten thenut on thebattery terminal tothe

following torque. .....1.7±0.25N·m(15±2lbin)

(4) Ground terminal

Tighten thenut on thebattery terminal tothe

following torque. ...2.25±0.25N·m(20±2lbin)

(5) Switch terminal

Tighten thenut on thebattery terminal tothe

following torque. ...2.25±0.25N·m(20±2lbin)

g01178443

Illustration 61

Note:Thewireterminalthatisontheswitchterminal

mustbeinsulated withheatshrinktubing.Donotuse

molded terminals.

(1) Sensor assembly

Tighten the sensor assembly tothe following

torque. ........................... 20±3N·m(15±2lbft)

This document is printed from SPI². Not for RESALE

![]()

![]()

32

Specifications Section

KENR6905

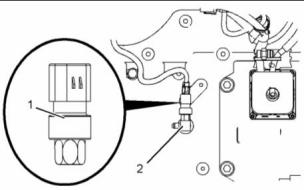

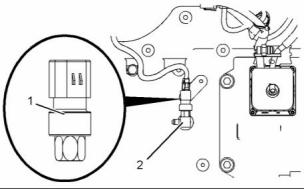

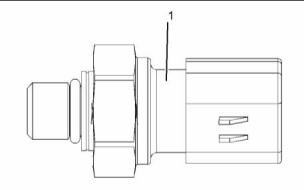

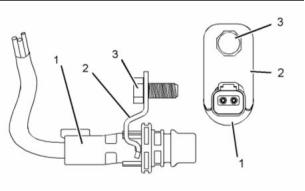

i02796853

i02797079

EngineOilPressureSensor

InletAirTemperatureSensor

g01382381

g01291117

Illustration 62

Illustration 64

Typical example

Typical example

(1) Sensor assembly

(1) Sensor assembly

Tighten sensor assembly to the following

torque.............................................. 10N·m(90lbin)

Torqueforsensor ............................ 20N·m(15lbft)

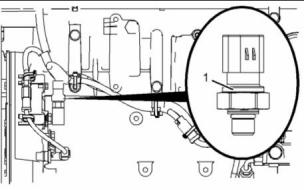

i02797099

InletManifold AirPressure

Sensor

i02796219

AtmosphericPressureSensor

g01388477

Illustration 63

g01291505

Illustration 65

Typical example

Typical example

(1) Sensor assembly

(1) Tighten the sensor to the following

torque. ...................................... 10N·m(90lbin)

Tighten the sensor assembly to the following

torque.............................................. 10N·m(90lbin)

This document is printed from SPI². Not for RESALE

![]()

KENR6905

33

Specifications Section

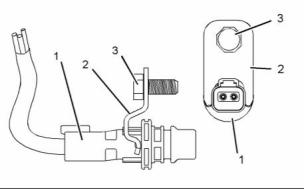

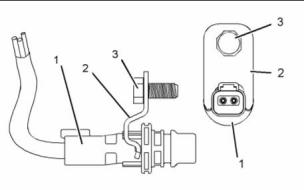

i02797163

Ensure thatthebracketisinstalled intheorientation

that isshown.

Speed/TimingSensor

CrankshaftPositionSensor

(3) Tightentheboltforthesensor tothefollowing

torque. ...................................... 25N·m(18lbft)

Ensure thatthesensor isseated before theboltis

tightened.

g01291129

Illustration 66

Typical example

(1) Sensor

(2) Bracket

Ensure thatthebracket isinstalled intheorientation

that isshown.

(3) Tightentheboltforthesensor tothefollowing

torque. ...................................... 25N·m(18lbft)

Ensure thatthesensor isseated before theboltis

tightened.

CamshaftPositionSensor

g01291129

Illustration 67

Typical example

(1) Sensor

(2) Bracket

This document is printed from SPI². Not for RESALE

![]()

34

Index Section

KENR6905

Index

A

H

Alternator andRegulator....................................... 30

Atmospheric PressureSensor............................... 32

Housing (Front)...................................................... 26

I

B

Important SafetyInformation.................................

2

BeltTightener........................................................ 29

InletAirTemperatureSensor................................. 32

InletManifold AirPressure Sensor........................ 32

C

M

Camshaft............................................................... 14

Connecting Rod..................................................... 24

Connecting RodBearingJournal........................... 23

Coolant TemperatureSensor................................. 31

Crankshaft ............................................................ 21

Crankshaft Seals................................................... 22

Cylinder Block........................................................ 19

Cylinder Head........................................................ 11

Cylinder HeadValves............................................ 10

Cylinder Liner........................................................ 21

MainBearing Journal............................................. 23

P

PistonandRings................................................... 24

PistonCoolingJet.................................................. 25

S

E

Specifications Section........................................... 4

Speed/Timing Sensor............................................ 33

Camshaft PositionSensor................................. 33

Crankshaft Position Sensor............................... 33

Electric Starting Motor........................................... 30

Electronic UnitInjector...........................................

Electronic UnitInjectorMechanism.......................

Electronic UnitInjectorRockerArm.......................

Electronic UnitInjectorWiring...............................

EngineDesign.......................................................

6

7

7

8

4

T

EngineOilFilterBase............................................ 15

EngineOilPan....................................................... 17

EngineOilPressure Sensor.................................. 32

EngineOilPump.................................................... 16

Exhaust Elbow....................................................... 14

Exhaust Manifold................................................... 13

TableofContents...................................................

3

Turbocharger......................................................... 13

V

ValveMechanism ..................................................

ValveMechanism Cover........................................

9

9

F

VibrationDamper................................................... 22

FanDrive............................................................... 29

Flywheel................................................................ 28

Flywheel Housing.................................................. 28

Flywheel Housing Cover........................................ 28

W

WaterLines........................................................... 17

WaterPump........................................................... 19

WaterTemperatureRegulator............................... 18

WaterTemperatureRegulator Housing................. 18

FuelFilter(Primary)...............................................

FuelFilterBase.....................................................

FuelPrimingPump................................................

5

5

6

FuelTemperatureSensor...................................... 31

FuelTransferPump...............................................

4

G

GearGroup(Front)................................................ 27

This document is printed from SPI². Not for RESALE

![]()

400-100-8969 15088860848

0574-26871589 15267810868

0574-26886646 15706865167

0574-26871569 18658287286

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文(简)

中文(简) Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska