详细描述

麦克福斯约翰迪尔发动机零配件

|

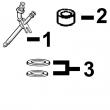

约翰迪尔 4045T 4.5T 活塞(米) RE59277/RE505100

|

|

||||||||||||||||||||||||||||

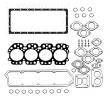

(1)这些标记号RE59277,RE505100要求使用Ring Set TRE66271。约翰迪尔已经停产

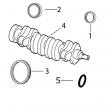

(2)使用机器拆分连杆使用TR114083,并使用TR501124与破裂的分裂连接杆。

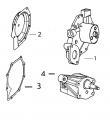

(3)与Oil Pan code 1901,1902& 1903年,钢制油锅。

(4)使用Oil Pan code 1904& 1905年,为铝油盘。

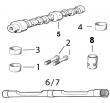

(5)用法兰头帽螺钉替换所有R78558带帽螺钉TR85363。

(6)(m)R135439,R132324,R134213。

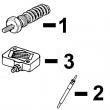

(7)线路连接都是线程化的。

(8)  在曲轴加工过程中必须保持适当的轴承轴颈半径,以确保正确的操作。

(9)1件组合式密封和穿套;替换TRE59810,RE538097。

(10)检查应用程序是否正确使用。

(11)与Stanadyne DE10注射泵一起使用。

(12)锥形鼻子。

(13)直鼻。

(14)线路连接是一个 软管倒钩&一个线程。

(15)线路连接是两个软管倒钩。

(16)机器分体式和断裂式分体式连杆均可用于同一台发动机,但每个连杆必须使用正确的连杆螺栓。

美国强鹿JOHN DEERE柴油发电机配件及发动机配件:

CD3029DF128、CD4039DF008、CD4045TF258、PE4045、CD6068TF158、CD6068TF258、CD6068HF158、CD6068HF258、CD6081HF001A、4045TFM75、CD6081HF001B、CD6125HF070A、CD6125HF070B、RG6125、6135H458。4045DFM70, 4045TFM75, 6068TFM75, 6068TFM76、4039DFM RE522528、RE519774、RE532628、RE518176、RE507980、RE518503、RE522515、RE504836、RE509031