详细描述

麦克福斯约翰迪尔发动机零配件

约翰迪尔 6081 高压缩活塞

|

|

|||||||||||||||||||||||||||

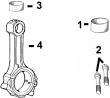

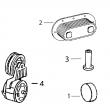

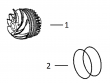

(1)用螺旋油泵驱动齿轮。 不要与HPCR燃油系统一起使用。

(2)带直油泵传动齿轮。

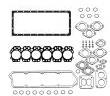

(3)纸垫片。

(4)金属/橡胶垫圈。

(5)套件中均包含前部密封件。

(6)检查应用程序是否正确使用。

T19044、RE62418、RE62419、RE521248、RE520842、C085004、RE509672、RE196945、RE191915、RE522688、RE522687、RE519774、RE532628、RE507980、RE531703、RE24619、RE187966、RE205726、RE507264、RE504836、RE509036、RE533910、RE532952、RE530107、RE508971

GRID PAGE GRID PAGE

A 9H23 AIR CONDITIONER COMPRESSOR (LOW MOUNT)

(USE W/ADJ FAN NO AUX DRIVE) (7406) 7400 - 7410

10D17 ACCESSORY PARTS (9901) 9900 - 9930 9I9 AIR CONDITIONER COMPRESSOR (LOW MOUNT)

9K9 ADAPTER KIT, AUX DRIVE 9 & 13 TOOTH, LH (USE W/ADJ FAN NO AUX DRIVE) (7412) 7400 - 7422

(9701) 9700 - 9704 9I15 AIR CONDITIONER COMPRESSOR (LOW MOUNT)

9K10 ADAPTER KIT, AUX DRIVE 9 & 9 TOOTH, LH (USE W/ADJ FAN NO AUX DRIVE) (7422) 7400 - 7428

(9701) 9700 - 9705 9I17 AIR CONDITIONER COMPRESSOR (LOW MOUNT)

8C15 ADJUSTABLE FAN DRIVE (2303) . 2300 - 2302 (USE W/ADJ FAN NO AUX DRIVE) (7426) 7400 - 7430

8C21 ADJUSTABLE FAN DRIVE (2307) (TF) .. 2300 - 2308 9J1 AIR CONDITIONER COMPRESSOR (LOW MOUNT)

8D10 ADJUSTABLE FAN DRIVE (2337) (TF) .. 2300 - 2322 (USE W/ADJ FAN NO AUX DRIVE) (7432) 7400 - 7438

8E13 ADJUSTABLE FAN DRIVE (2355) (TF) .. 2300 - 2350 9H17 AIR CONDITIONER COMPRESSOR (LOW MOUNT)

8E14 ADJUSTABLE FAN DRIVE (2356) (TF) .. 2300 - 2351 (USE W/ADJ FAN NO AUX DRIVE)(7402) 7400 - 7404

8E15 ADJUSTABLE FAN DRIVE (2357) (TF) .. 2300 - 2352 9H15 AIR CONDITIONER COMPRESSOR (LOW MOUNT)

8E16 ADJUSTABLE FAN DRIVE (2359) (TF) .. 2300 - 2353 (USE W/FIXED FAN NO AUX DRIVE) (7401)7400 - 7402

8E17 ADJUSTABLE FAN DRIVE (2359) (TF) .. 2300 - 2354 9I7 AIR CONDITIONER COMPRESSOR (LOW MOUNT)

7G16 AFTERCOOLER (1702) (AF).. 1700 - 1702 (USE W/FIXED FAN NO AUX DRIVE) (7411)7400 - 7420

7G21 AFTERCOOLER (1704) (AF).. 1700 - 1708 9I13 AIR CONDITIONER COMPRESSOR (LOW MOUNT)

7H1 AFTERCOOLER (1705) (AF).. 1700 - 1712 (USE W/FIXED FAN NO AUX DRIVE) (7421)7400 - 7426

7H5 AFTERCOOLER (1706) (AF).. 1700 - 1716 9I23 AIR CONDITIONER COMPRESSOR (LOW MOUNT)

7H9 AFTERCOOLER (1707) (AF).. 1700 - 1720 (W/FIXED FAN NO AUX DRIVE) (7431) 7400 - 7436

7H13 AFTERCOOLER (1708) (AF).. 1700 - 1724 9K15 AIR CONDITIONER COMPRESSOR KIT

7H17 AFTERCOOLER (1709) (AF).. 1700 - 1728 (ADJ FAN, NO AUX DRIVE) (9701) 9700 - 9710

7H21 AFTERCOOLER (1710) (AF).. 1700 - 1732 9K13 AIR CONDITIONER COMPRESSOR KIT

7H23 AFTERCOOLER (1711) (AF).. 1700 - 1734 (FIXED FAN, NO AUX DRIVE) (9701) 9700 - 9708

7I1 AFTERCOOLER (1712) (AF).. 1700 - 1736 9J5 AIR CONDITIONER COMPRESSOR, NO

7I3 AFTERCOOLER (1713) (AF).. 1700 - 1738 (7498) 7400 - 7442

7I5 AFTERCOOLER (1714) (AF).. 1700 - 1740 9K21 AIR GOVERNOR (9701) 9700 - 9716

7I7 AFTERCOOLER (1715) (AF).. 1700 - 1742 7G15 AIR INTAKE (1701) (HF) 1700 - 1701

7I9 AFTERCOOLER (1716) (AF).. 1700 - 1744 7G16 AIR INTAKE (1702) (AF) 1700 - 1702

7I11 AFTERCOOLER (1717) (AF).. 1700 - 1746 7G18 AIR INTAKE (1702) (HF) 1700 - 1704

7I13 AFTERCOOLER (1718) (AF).. 1700 - 1748 7G19 AIR INTAKE (1703) (TF) 1700 - 1706

7I17 AFTERCOOLER (1731) (AF).. 1700 - 1752 7G21 AIR INTAKE (1704) (AF) 1700 - 1708

7I20 AFTERCOOLER (1737) (AF).. 1700 - 1756 7G24 AIR INTAKE (1704) (HF) 1700 - 1711

9L6 AIR CLEANER (9701) (AF,TF) 9700 - 9726 7G23 AIR INTAKE (1704) (TF) 1700 - 1710

9L2 AIR CLEANER, HEAVY DUTY (9701) 9700 - 9722 7H1 AIR INTAKE (1705) (AF) 1700 - 1712

9L4 AIR CLEANER, LIGHT DUTY (9701) . 9700 - 9724 7H4 AIR INTAKE (1705) (HF) 1700 - 1715

9J16 AIR COMPRESSOR (HOLSET) (7804) 7800 - 7804 7H3 AIR INTAKE (1705) (TF) 1700 - 1714

9J17 AIR COMPRESSOR (HOLSET) (7804) 7800 - 7806 7H5 AIR INTAKE (1706) (AF) 1700 - 1716

9J19 AIR COMPRESSOR (HOLSET) (7805) 7800 - 7808 7H7 AIR INTAKE (1706) (TF) 1700 - 1718

9J20 AIR COMPRESSOR (HOLSET) (7805) 7800 - 7810 7H9 AIR INTAKE (1707) (AF) 1700 - 1720

9J13 AIR COMPRESSOR (MIDLAND) (7802).. 7800 - 7801 7H11 AIR INTAKE (1707) (TF) 1700 - 1722

9J14 AIR COMPRESSOR (MIDLAND) (7802).. 7800 - 7802 7H13 AIR INTAKE (1708) (AF) 1700 - 1724

9K19 AIR COMPRESSOR KIT (HOLSET) 7H15 AIR INTAKE (1708) (TF) 1700 - 1726

(9701) 9700 - 9714 7H17 AIR INTAKE (1709) (AF) 1700 - 1728

10C15 AIR COMPRESSOR KIT (MIDLAND) . 9900 - 9901 7H19 AIR INTAKE (1709) (TF) 1700 - 1730

9K17 AIR COMPRESSOR KIT (MIDLAND) 7H21 AIR INTAKE (1710) (AF) 1700 - 1732

(9701) 9700 - 9712 7H23 AIR INTAKE (1711) (AF) 1700 - 1734

9H19 AIR CONDITIONER COMPRESSOR (HIGH MOUNT) 7I1 AIR INTAKE (1712) (AF) 1700 - 1736

(USE W/ADJ FAN LH AUX DRIVE) (7403) 7400 - 7406 7I3 AIR INTAKE (1713) (AF) 1700 - 1738

9H21 AIR CONDITIONER COMPRESSOR (HIGH MOUNT) 7I5 AIR INTAKE (1714) (AF) 1700 - 1740

(USE W/ADJ FAN LH AUX DRIVE) (7405) 7400 - 7408 7I7 AIR INTAKE (1715) (AF) 1700 - 1742

9H24 AIR CONDITIONER COMPRESSOR (HIGH MOUNT) 7I9 AIR INTAKE (1716) (AF) 1700 - 1744

(USE W/ADJ FAN LH AUX DRIVE) (7407) 7400 - 7412 7I11 AIR INTAKE (1717) (AF) 1700 - 1746

9I1 AIR CONDITIONER COMPRESSOR (HIGH MOUNT) 7I13 AIR INTAKE (1718) (AF) 1700 - 1748

(USE W/ADJ FAN LH AUX DRIVE) (7408) 7400 - 7414 7I16 AIR INTAKE (1726) (HF) 1700 - 1751

9I3 AIR CONDITIONER COMPRESSOR (HIGH MOUNT) 7I15 AIR INTAKE (1726) (TF) 1700 - 1750

(USE W/ADJ FAN LH AUX DRIVE) (7409) 7400 - 7416 7I17 AIR INTAKE (1731) (AF) 1700 - 1752

9I5 AIR CONDITIONER COMPRESSOR (HIGH MOUNT) 7I19 AIR INTAKE (1733) (HF) 1700 - 1754

(USE W/ADJ FAN LH AUX DRIVE) (7410) 7400 - 7418 7I20 AIR INTAKE (1737) (AF) 1700 - 1756

9I11 AIR CONDITIONER COMPRESSOR (HIGH MOUNT) 7I22 AIR INTAKE (1738) (TF) 1700 - 1758

(USE W/ADJ FAN LH AUX DRIVE) (7418) 7400 - 7424 8I1 ALTERNATOR (12V 120AMP) (BOSCH) (3104) 3100 - 3104

9I19 AIR CONDITIONER COMPRESSOR (HIGH MOUNT) 8I2 ALTERNATOR (12V 95AMP) (BOSCH) (3105) .. 3100 - 3105

(USE W/ADJ FAN LH AUX DRIVE) (7428) 7400 - 7432 8I10 ALTERNATOR (12V-90AMP) (DENSO) (3143) .. 3100 - 3112

9I21 AIR CONDITIONER COMPRESSOR (HIGH MOUNT) 8H23 ALTERNATOR (12V, 140 AMP) (DENSO) (3101) .. 3100 - 3101

(USE W/ADJ FAN LH AUX DRIVE) (7429) 7400 - 7434 8H24 ALTERNATOR (12V, 200 AMP)

9J3 AIR CONDITIONER COMPRESSOR (HIGH MOUNT) (LEECE-NEVILLE) (3102) .. 3100 - 3102

(USE W/ADJ FAN LH AUX DRIVE) (7438) 7400 - 7440 8I6 ALTERNATOR (12V, 98 AMP) (DELPHI) (3140) 3100 - 3108

I-12 POWERTECH 8.1 L OEM ENGINE (ESN -199999) PC2527 (10-DEC-02)

8I7 ALTERNATOR (24V, 40 AMP) (DELPHI) (3142) 3100 - 3109 8L15 AUXILIARY DRIVE 9 & 9 TOOTH SPLINE

8I3 ALTERNATOR (24V, 60 AMP) (DENSO) (3106) 3100 - 3106 (5202) 5200 - 5204

8H25 ALTERNATOR (24V, 80 AMP) (BOSCH) (3103) 3100 - 3103 8L17 AUXILIARY DRIVE 9 & 9 TOOTH SPLINE

8I4 ALTERNATOR (3107) 3100 - 3107 (5203) 5200 - 5206

9D6 ALTERNATOR BRACKET (6204) 6200 - 6204 9K7 AUXILIARY DRIVE, LEFT HAND, BASE, KIT

9D8 ALTERNATOR BRACKET (6205) 6200 - 6206 (9701) 9700 - 9702

9D10 ALTERNATOR BRACKET (6206) 6200 - 6209 9K11 AUXILIARY DRIVE, RIGHT HAND KIT

9D11 ALTERNATOR BRACKET (6209) 6200 - 6210 (9701) 9700 - 9706

9D13 ALTERNATOR BRACKET (6213) 6200 - 6212

9D15 ALTERNATOR BRACKET (6215) 6200 - 6214

8I8 ALTERNATOR COMPONENTS (3142) B

(DENSO) (24V 40 AMP) 3100 - 3110

8H25 ALTERNATOR PULLEY (BOSCH) (3103) .. 3100 - 3103 8K7 BEARING CAPS, MAIN (4602) 4600 - 4602

8I1 ALTERNATOR PULLEY (BOSCH) (3104) .. 3100 - 3104 8K10 BEARING CAPS, MAIN (4603) (TF) 4600 - 4606

8I2 ALTERNATOR PULLEY (BOSCH) (3105) .. 3100 - 3105 8K13 BEARING CAPS, MAIN (4604) (AF) 4600 - 4610

8H23 ALTERNATOR PULLEY (DENSO) (3101) .. 3100 - 3101 8K17 BEARINGS, CRANKSHAFT AND DRIVE

8I3 ALTERNATOR PULLEY (DENSO) (3106) .. 3100 - 3106 GEAR (4701) 4700 - 4701

8H24 ALTERNATOR PULLEY (LEECE-NEVILLE) 8K18 BEARINGS, CRANKSHAFT AND DRIVE

(3102) 3100 - 3102 GEAR (4702) 4700 - 4702

9D4 ALTERNATOR SUPPORT (6202) 6200 - 6202 9D4 BELT TENSIONER (6202).. 6200 - 6202

9D5 ALTERNATOR SUPPORT (6203) 6200 - 6203 9D5 BELT TENSIONER (6203).. 6200 - 6203

8I5 ALTERNATOR W/TVP (12V, 200 AMP) (3108) 9D6 BELT TENSIONER (6204).. 6200 - 6204

(LEECE-NEVILLE) (AF,HF) 3100 - 3107A 9D8 BELT TENSIONER (6205).. 6200 - 6206

10D4 AMMETER GAUGE 9900 - 9916 9D10 BELT TENSIONER (6206).. 6200 - 6209

10D4 AMMETER, GAUGE9900 - 9916 9D11 BELT TENSIONER (6209).. 6200 - 6210

2D23 ANEROID ACTIVATOR, HYDRAULIC 9D13 BELT TENSIONER (6213).. 6200 - 6212

(1602) (AF,TF,HF) .. 1600 - 1630 9D15 BELT TENSIONER (6215).. 6200 - 6214

3D25 ANEROID ACTIVATOR, HYDRAULIC 9D17 BELT TENSIONER (6297).. 6200 - 6216

1600F - 1628 8F11 BELT, FAN (POLY-VEE) (2414) . 2400 - 2414

2D7 ANEROID ACTIVATOR, HYDRAULIC (1601) 8F12 BELT, FAN (POLY-VEE) (2415) . 2400 - 2415

(AF,TF,HF) 1600 - 1614 8F13 BELT, FAN (POLY-VEE) (2416) . 2400 - 2416

2G9 ANEROID ACTIVATOR, HYDRAULIC (1605) 8F14 BELT, FAN (POLY-VEE) (2417) . 2400 - 2417

(TF,HF). 1600 - 1688 8F15 BELT, FAN (POLY-VEE) (2418) . 2400 - 2418

2H9 ANEROID ACTIVATOR, HYDRAULIC (1606) 8F16 BELT, FAN (POLY-VEE) (2419) . 2400 - 2419

(AF) ..1600 - 1715 8F17 BELT, FAN (POLY-VEE) (2420) . 2400 - 2420

3F13 ANEROID ACTIVATOR, HYDRAULIC (1612) (TF)

8G11 BELT, FAN (POLY-VEE) (2449) . 2400 - 2439 9J17 COMPRESSOR, AIR (HOLSET) (7804) .. 7800 - 7806

8G12 BELT, FAN (POLY-VEE) (2450) . 2400 - 2440 9J19 COMPRESSOR, AIR (HOLSET) (7805) .. 7800 - 7808

8K7 BLOCK FITTINGS (4602) .. 4600 - 4602 9J20 COMPRESSOR, AIR (HOLSET) (7805) .. 7800 - 7810

8K10 BLOCK FITTINGS (4603) (TF) 4600 - 4606 9J13 COMPRESSOR, AIR (MIDLAND) (7802) 7800 - 7801

8K13 BLOCK FITTINGS (4604) (AF) 4600 - 4610 9J14 COMPRESSOR, AIR (MIDLAND) (7802) 7800 - 7802

10C19 BLOCK, SHORT (WITH HEAD BOLTS) .. 9900 - 9906 9H19 COMPRESSOR, AIR CONDITIONER (HIGH MOUNT)

9L11 BLOWER FAN (26", 660MM)(8-BLADE) (9701) .. 9700 - 9731 (USE W/ADJ FAN LH AUX DRIVE) (7403) 7400 - 7406

9L10 BLOWER FAN (28", 711MM)(8-BLADE) (9701) .. 9700 - 9730 9H21 COMPRESSOR, AIR CONDITIONER (HIGH MOUNT)

9L13 BLOWER FAN (9701) 9700 - 9733 (USE W/ADJ FAN LH AUX DRIVE) (7405) 7400 - 7408

9D6 BRACKET, ALTERNATOR (6204) 6200 - 6204 9H24 COMPRESSOR, AIR CONDITIONER (HIGH MOUNT)

9D8 BRACKET, ALTERNATOR (6205) 6200 - 6206 (USE W/ADJ FAN LH AUX DRIVE) (7407) 7400 - 7412

9D10 BRACKET, ALTERNATOR (6206) 6200 - 6209 9I1 COMPRESSOR, AIR CONDITIONER (HIGH MOUNT)

9D11 BRACKET, ALTERNATOR (6209) 6200 - 6210 (USE W/ADJ FAN LH AUX DRIVE) (7408) 7400 - 7414

9D13 BRACKET, ALTERNATOR (6213) 6200 - 6212 9I3 COMPRESSOR, AIR CONDITIONER (HIGH MOUNT)

9D15 BRACKET, ALTERNATOR (6215) 6200 - 6214 (USE W/ADJ FAN LH AUX DRIVE) (7409) 7400 - 7416

2G8 BRACKET, FUEL SHUT-OFF (MECH) 9I5 COMPRESSOR, AIR CONDITIONER (HIGH MOUNT)

(1605) (TF,HF) ..1600 - 1687 (USE W/ADJ FAN LH AUX DRIVE) (7410) 7400 - 7418

3I10 BRACKET, FUEL SHUT-OFF (MECH) 9I11 COMPRESSOR, AIR CONDITIONER (HIGH MOUNT)

1600A - 1591 (USE W/ADJ FAN NO AUX DRIVE) (7406) 7400 - 7410

10C17 BUSHING, CAMSHAFT .. 9900 - 9904 9I9 COMPRESSOR, AIR CONDITIONER (LOW MOUNT)

8K7 BUSHING, CAMSHAFT (4602) 4600 - 4602 (USE W/ADJ FAN NO AUX DRIVE) (7412) 7400 - 7422

8K10 BUSHING, CAMSHAFT (4603) (TF) 4600 - 4606 9I15 COMPRESSOR, AIR CONDITIONER (LOW MOUNT)

8K13 BUSHING, CAMSHAFT (4604) (AF) 4600 - 4610 (USE W/ADJ FAN NO AUX DRIVE) (7422) 7400 - 7428

9I17 COMPRESSOR, AIR CONDITIONER (LOW MOUNT)

(USE W/ADJ FAN NO AUX DRIVE) (7426) 7400 - 7430

C 9J1 COMPRESSOR, AIR CONDITIONER (LOW MOUNT)

(USE W/ADJ FAN NO AUX DRIVE) (7432) 7400 - 7438

8L3 CAM FOLLOWER (4902)4900 - 4901 9H15 COMPRESSOR, AIR CONDITIONER (LOW MOUNT)

8K6 CAMSHAFT (4602) 4600 - 4601 (USE W/FIXED FAN NO AUX DRIVE) (7401)7400 - 7402

8K9 CAMSHAFT (4603) (TF) 4600 - 4604 9I7 COMPRESSOR, AIR CONDITIONER (LOW MOUNT)

8K12 CAMSHAFT (4604) (AF) 4600 - 4608 (USE W/FIXED FAN NO AUX DRIVE) (7411)7400 - 7420

10C17 CAMSHAFT BUSHING .. 9900 - 9904 9I13 COMPRESSOR, AIR CONDITIONER (LOW MOUNT)

8K7 CAMSHAFT BUSHING (4602) 4600 - 4602 (USE W/FIXED FAN NO AUX DRIVE) (7421)7400 - 7426

8K10 CAMSHAFT BUSHING (4603) (TF) 4600 - 4606 9I23 COMPRESSOR, AIR CONDITIONER (LOW MOUNT)

8K13 CAMSHAFT BUSHING (4604) (AF) 4600 - 4610 (W/FIXED FAN NO AUX DRIVE) (7431) 7400 - 7436

10C25 CAMSHAFT WITH FOLLOWERS (PARTS) 9900 - 9912 10C15 COMPRESSOR, AIR, KIT (MIDLAND) 9900 - 9901

1C13 CAP, OIL FILL (CENTER FILL) (1101) 1100 - 1102 9J5 COMPRESSOR, NO AIR CONDITIONER (7498) .. 7400 - 7442

10C17 CAPS, MAIN BEARING .. 9900 - 9904 10D17 CONDITIONER, COOLANT (9901) . 9900 - 9930

8K7 CAPS, MAIN BEARING (4602) 4600 - 4602 8K21 CONNECTING ROD (4801) (AF, TF) . 4800 - 4801

8K10 CAPS, MAIN BEARING (4603) (TF) 4600 - 4606 8K22 CONNECTING ROD (4802) (AF,HF) . 4800 - 4802

8K13 CAPS, MAIN BEARING (4604) (AF) 4600 - 4610 8K23 CONNECTING ROD (4803) (AF, TF) . 4800 - 4803

9L17 CHARGED AIR COOLER 10D19 CONNECTORS, ELECTRICAL, WEATHERPACK .. 9900 - 9932

(BLOWER FAN) (HF) (9701) 9700 - 9738 5G3 CONNECTORS, FIJ HOUSING (ELEC GOV)

9L2 CLEANER, AIR, HEAVY DUTY (9701) 9700 - 9722 2D8 CONNECTORS, FIP HOUSING (ELEC GOV)

9L4 CLEANER, AIR, LIGHT DUTY (9701). 9700 - 9724 (1601) (AF) (ESN -068144) . 1600 - 1615

9K19 COMPRESSOR KIT, AIR (HOLSET) 2D9 CONNECTORS, FIP HOUSING (ELEC GOV)

(9701) 9700 - 9714 (1601) (TF,HF) (ESN (AF) 068145- ) 1600 - 1616

9K17 COMPRESSOR KIT, AIR (MIDLAND) 2D24 CONNECTORS, FIP HOUSING (ELEC GOV)

(9701) 9700 - 9712 (1602) (AF) (ESN -068144) . 1600 - 1631

9K15 COMPRESSOR KIT, AIR CONDITIONER 2E17 CONNECTORS, FIP HOUSING (ELEC GOV)

(ADJ FAN, NO AUX DRIVE) (9701) 9700 - 9710 (1603) (AF,HF)..1600 - 1649

9K13 COMPRESSOR KIT, AIR CONDITIONER 2E18 CONNECTORS, FIP HOUSING (ELEC GOV)

(FIXED FAN, NO AUX DRIVE) (9701) 9700 - 9708 (1603) (TF) 1600 - 1650

9J16 COMPRESSOR, AIR (HOLSET) (7804) .. 7800 - 7804

I2F14 CONNECTORS, FIP HOUSING (ELEC GOV) 5D22 CONNECTORS, FIP HOUSING (ELEC GOV)

(1604) (TF) 1600 - 1669 (1641) (AF,HF)..阿里强鹿滤芯滤清器RE21748找哪家,台湾强鹿6081发动机活塞缸套组件供货商,泉州强鹿水温传感器el52222市场报价,淮北约翰迪尔强鹿5010E拖拉机KV16429AT171854空气滤芯市场报价,天水johndeere约翰迪尔水泵哪家好,海南强鹿柴油机皮带R134636/R503312市场报价,信阳约翰迪尔R113612价格行情,通化约翰迪尔强鹿4045缸套厂家供货,文山约翰迪尔衬垫套RE527832厂家供应,玉林强鹿柴油机水泵RE530870批发价,香港岛强鹿RE44574曲轴后油封厂家供货,台南强鹿6081发动机活塞环哪家好,黄山约翰迪尔强鹿4045柴油机止推轴承RE65912的价格,温州约翰迪尔机油冷却器RE59296批发价,乌鲁木齐强鹿4045柴油机气门弹簧座的价格,安庆强鹿6068柴油机气缸盖螺丝找哪家,德州强鹿起动机RE70960代理,汉中强鹿3029柴油机排气门价格,焦作强鹿柴油发电机配件曲轴后油封RE53687代理商,果洛约翰迪尔强鹿4045柴油机左平衡轴TRE500449供应商,金昌强鹿柴油滤芯RE546336批发商,

10D17 COOLANT SAMPLING KIT (9901) . 9900 - 9930 1D1 DAMPER, CRANKSHAFT (1346) 1300 - 1310

9C20 COOLER, OIL (5901).. 5900 - 5904 1D2 DAMPER, CRANKSHAFT (1348)

9C25 COOLER, OIL (5914).. 5900 - 5910 (AF, TF) 1300 - 1311

7J6 COVER, DIPSTICK (1906) 1900 - 1904 1C20 DAMPER, CRANKSHAFT, NO PULLEY GROOVES

7J9 COVER, DIPSTICK (1908) 1900 - 1908 (1304) 1300 - 1304

7J12 COVER, DIPSTICK (1909) 1900 - 1912 1C17 DAMPERS, CRANKSHAFT (1302) . 1300 - 1301

7J15 COVER, DIPSTICK (1910) 1900 - 1916 1C18 DAMPERS, CRANKSHAFT (1303) . 1300 - 1302

7J18 COVER, DIPSTICK (1911) 1900 - 1920 1C24 DAMPERS, CRANKSHAFT (1341) . 1300 - 1308

7J24 COVER, DIPSTICK (1913) 1900 - 1928 8I5 DIODE TVP (12V) (3108) (AF,HF) . 3100 - 3107A

7K7 COVER, DIPSTICK (1916) 1900 - 1938 6C23 DIODE, TRANSIENT VOLTAGE PROTECTION

7J4 COVER, FLYWHEEL HOUSING (1905) .. 1900 - 1902 (1650) (AF)

9J8 COVER, TIMING GEAR (7701) 7700 - 7702 8J13 DIPSTICK AND TUBE, ENGINE OIL (4002) .. 4000 - 4001

9J10 COVER, TIMING GEAR (7702) 7700 - 7704 8J15 DIPSTICK AND TUBE, ENGINE OIL (4006) .. 4000 - 4003

9C14 COVER, WATER PUMP (5701) (ESN XXXXXX- ) 5700 - 5702 8J19 DIPSTICK AND TUBE, ENGINE OIL (4010) .. 4000 -

10D8 CRANKSHAFT .. 9900 - 9920 8J20 DIPSTICK AND TUBE, ENGINE OIL (4011) .. 4000 - 4008

10C23 CRANKSHAFT (0.292 UNDERSIZE PIN 8J21 DIPSTICK AND TUBE, ENGINE OIL (4016) .. 4000 - 4009

JOURNALS) (ESN -142156) 9900 - 9910 8J22 DIPSTICK AND TUBE, ENGINE OIL (4017) .. 4000 - 4010

8K17 CRANKSHAFT (4701) 4700 - 4701 7J6 DIPSTICK COVER (1906) .. 1900 - 1904

8K18 CRANKSHAFT (4702) 4700 - 4702 7J9 DIPSTICK COVER (1908) .. 1900 - 1908

1C24 CRANKSHAFT DAMPERS (1341) 1300 - 1308 7J12 DIPSTICK COVER (1909) .. 1900 - 1912

9J8 CRANKSHAFT FRONT OIL SEAL (7701) .. 7700 - 7702 7J15 DIPSTICK COVER (1910) .. 1900 - 1916

9J10 CRANKSHAFT FRONT OIL SEAL (7702) .. 7700 - 7704 7J18 DIPSTICK COVER (1911) .. 1900 - 1920

1C20 CRANKSHAFT PULLEY AND DAMPER (1304).. 1300 - 1304 7J24 DIPSTICK COVER (1913) .. 1900 - 1928

1C21 CRANKSHAFT PULLEY AND DAMPER (1306).. 1300 - 1305 7K7 DIPSTICK COVER (1916) .. 1900 - 1938

1C22 CRANKSHAFT PULLEY AND DAMPER (1307).. 1300 - 1306 8J14 DIPSTICK, ENGINE OIL TUBE AND

1C23 CRANKSHAFT PULLEY AND DAMPER (1311) (AF) 1300 - 1307 HOUSING (4003)4000 - 4002

1C25 CRANKSHAFT PULLEY AND DAMPER (1345).. 1300 - 1309 8J23 DIPSTICK, TUBE AND HOUSING

1D1 CRANKSHAFT PULLEY AND DAMPER (1346).. 1300 - 1310 ENGINE OIL (4018)4000 - 4011

1D2 CRANKSHAFT PULLEY AND DAMPER (1348) 8J16 DIPSTICK, TUBE AND HOUSING,

(AF, TF) 1300 - 1311 ENGINE OIL (4007)4000 - 4004

1C17 CRANKSHAFT PULLEY AND DAMPERS (1302) .. 1300 - 1301 8J17 DIPSTICK, TUBE AND HOUSING,

1C18 CRANKSHAFT PULLEY AND DAMPERS (1303) .. 1300 - 1302 ENGINE OIL (4008)4000 - 4005

10C17 CYLINDER BLOCK FITTINGS 9900 - 9904 8J18 DIPSTICK, TUBE AND HOUSING,

8K7 CYLINDER BLOCK FITTINGS (4602). 4600 - 4602 ENGINE OIL (4009)4000 - 4006

8K10 CYLINDER BLOCK FITTINGS (4603) (TF) 4600 - 4606 9K7 DRIVE KIT, BASE AUXILIARY, LEFT HAND

8K13 CYLINDER BLOCK FITTINGS (4604) (AF) 4600 - 4610 (9701) 9700 - 9702

8L9 CYLINDER HEAD (5109)5100 - 5102 9K10 DRIVE, AUX ADAPTER KIT, 9 & 9 TOOTH, LH

10D2 CYLINDER HEAD AND VALVES (PARTS) 9900 - 9914 (9701) 9700 - 9705

10D12 CYLINDER HEAD GASKET KIT . 9900 - 9924 9K9 DRIVE, AUX 9 & 13 TOOTH LH ADAPTER KIT

8K21 CYLINDER LINER, CONNECTING ROD, PISTON (9701) 9700 - 9704

(HIGH COMPRESSION) (4801) (AF, TF) 4800 - 4801 9K11 DRIVE, AUXILIARY, RIGHT HAND KIT

8K23 CYLINDER LINER, PISTON, CONNECTING ROD (9701) 9700 - 9706

(HIGH COMPRESSION) (4803) (AF, TF) 4800 - 4803

8K22 CYLINDER LINER, PISTON, CONNECTING ROD

9D21 ELBOW, EXHAUST (6401) 6400 - 6401 8F2 FAN BELT (POLY-VEE) (2405) 2400 - 2405

9D22 ELBOW, EXHAUST (6403) 6400 - 6402 8F3 FAN BELT (POLY-VEE) (2406) 2400 - 2406

9D23 ELBOW, EXHAUST (6406) 6400 - 6403 8F4 FAN BELT (POLY-VEE) (2407) 2400 - 2407

9K23 ELECTRIC HOUR METER (9701) . 9700 - 9718 8F5 FAN BELT (POLY-VEE) (2408) 2400 - 2408

10D19 ELECTRICAL TERMINALS AND CONNECTORS, 8F6 FAN BELT (POLY-VEE) (2409) 2400 - 2409

WEATHERPACK 9900 - 9932 8F7 FAN BELT (POLY-VEE) (2410) 2400 - 2410

3H23 ELECTRONIC CONTROL UNIT (1616) (AF) ..

1600A - 1630 8F8 FAN BELT (POLY-VEE) (2411) 2400 - 2411

4D21 ELECTRONIC CONTROL UNIT (1621) (AF) ..

1600B - 1630 8F9 FAN BELT (POLY-VEE) (2412) 2400 - 2412

4D23 ELECTRONIC CONTROL UNIT (1621) (HF) ..

1600B - 1632 8F10 FAN BELT (POLY-VEE) (2413) 2400 - 2413

4F19 ELECTRONIC CONTROL UNIT (1630) (HF) ..

1600B - 1680 8F11 FAN BELT (POLY-VEE) (2414) 2400 - 2414

4G5 ELECTRONIC CONTROL UNIT (1632) (AF) ..

1600B - 1688 8F12 FAN BELT (POLY-VEE) (2415) 2400 - 2415

4G15 ELECTRONIC CONTROL UNIT (1633) (AF) ..

1600B - 1696 8F13 FAN BELT (POLY-VEE) (2416) 2400 - 2416

4G17 ELECTRONIC CONTROL UNIT (1633) (HF) ..

1600B - 1698 8F14 FAN BELT (POLY-VEE) (2417) 2400 - 2417

4H3 ELECTRONIC CONTROL UNIT (1634) (AF) ..

1600B - 1712 8F15 FAN BELT (POLY-VEE) (2418) 2400 - 2418

4H13 ELECTRONIC CONTROL UNIT (1635) (AF) ..

1600B - 1722 8F16 FAN BELT (POLY-VEE) (2419) 2400 - 2419

4H23 ELECTRONIC CONTROL UNIT (1639) (HF) ..

1600B - 1732 8F17 FAN BELT (POLY-VEE) (2420) 2400 - 2420

5D3 ELECTRONIC CONTROL UNIT (1640) (HF) ..

1600C - 1612 8F18 FAN BELT (POLY-VEE) (2421) 2400 - 2421

5D18 ELECTRONIC CONTROL UNIT (1641) (AF) ..

1600C - 1628 8F19 FAN BELT (POLY-VEE) (2422) 2400 - 2422

5D20 ELECTRONIC CONTROL UNIT (1641) (HF) ..

1600C - 1630 8F20 FAN BELT (POLY-VEE) (2423) 2400 - 2423

5E5 ELECTRONIC CONTROL UNIT (1642) (AF) ..

1600C - 1640 8F21 FAN BELT (POLY-VEE) (2424) 2400 - 2424

5E7 ELECTRONIC CONTROL UNIT (1642) (HF) ..

1600C - 1642 8F22 FAN BELT (POLY-VEE) (2425) 2400 - 2425

5E19 ELECTRONIC CONTROL UNIT (1643) (AF) ..

1600C - 1654 8F23 FAN BELT (POLY-VEE) (2426) 2400 - 2426

5E21 ELECTRONIC CONTROL UNIT (1643) (HF) ..

1600C - 1656 8F24 FAN BELT (POLY-VEE) (2427) 2400 - 2427

5F9 ELECTRONIC CONTROL UNIT (1644) (AF) ..

1600C - 1668 8F25 FAN BELT (POLY-VEE) (2428) 2400 - 2428

5F11 ELECTRONIC CONTROL UNIT (1644) (HF) ..

1600C - 1670 8G1 FAN BELT (POLY-VEE) (2429) 2400 - 2429

5F23 ELECTRONIC CONTROL UNIT (1645) (AF) ..

1600C - 1682 8G2 FAN BELT (POLY-VEE) (2430) 2400 - 2430

5G1 ELECTRONIC CONTROL UNIT (1645) (HF) ..

1600C - 1684 8G3 FAN BELT (POLY-VEE) (2431) 2400 - 2431

5G13 ELECTRONIC CONTROL UNIT (1646) (AF) ..

1600C - 1696 8G4 FAN BELT (POLY-VEE) (2432) 2400 - 2432

5G15 ELECTRONIC CONTROL UNIT (1646) (HF) ..

1600C - 1698 8G5 FAN BELT (POLY-VEE) (2433) 2400 - 2433

5H3 ELECTRONIC CONTROL UNIT (1647) (AF) ..

1600C - 1710 8G6 FAN BELT (POLY-VEE) (2434) 2400 - 2434

5H5 ELECTRONIC CONTROL UNIT (1647) (HF) ..

1600C - 1712 8G7 FAN BELT (POLY-VEE) (2435) 2400 - 2435

5H17 ELECTRONIC CONTROL UNIT (1648) (AF) ..

1600C - 1724 8G8 FAN BELT (POLY-VEE) (2436) 2400 - 2436

5H19 ELECTRONIC CONTROL UNIT (1648) (HF) ..

1600C - 1726 8G9 FAN BELT (POLY-VEE) (2437) 2400 - 2437

5I5 ELECTRONIC CONTROL UNIT (1649) (AF) ..

1600C - 1736 8G10 FAN BELT (POLY-VEE) (2438) 2400 - 2438

6C23 ELECTRONIC CONTROL UNIT (1650) (AF) ..

1600D - 1608 8G11 FAN BELT (POLY-VEE) (2449) 2400 - 2439

8G12 FAN BELT (POLY-VEE) (2450) 2400 - 2440 10D6 FIELD INSTALLED KITS (12 VOLT INSTRUMENT

10D11 FAN BELT REPLACEMENT KIT. 9900 - 9923 PANEL) (ENCLOSED)9900 - 9918

8E18 FAN DRIVE, ADJUSTABLE (23AL). 2300 - 2356 8I19 FILTER, FUEL (FINAL) (3507) 3500 - 3508

8C15 FAN DRIVE, ADJUSTABLE (2303). 2300 - 2302 8I22 FILTER, FUEL (FINAL) (3509) (TF) 3500 - 3512

8C17 FAN DRIVE, ADJUSTABLE (2304). 2300 - 2304 8J3 FILTER, FUEL (FINAL) (3522) (AF,HF) .. 3500 - 3520

8C21 FAN DRIVE, ADJUSTABLE (2307) (TF).. 2300 - 2308 8I13 FILTER, FUEL (3503) (TF) 3500 - 3502

8C23 FAN DRIVE, ADJUSTABLE (2308). 2300 - 2310 8I15 FILTER, FUEL (3504) 3500 - 3504

8D1 FAN DRIVE, ADJUSTABLE (2309). 2300 - 2312 8I17 FILTER, FUEL (3506) 3500 - 3506

8D4 FAN DRIVE, ADJUSTABLE (2313). 2300 - 2316 8I20 FILTER, FUEL (3508) (TF) 3500 - 3510

8D6 FAN DRIVE, ADJUSTABLE (2314). 2300 - 2318 8I23 FILTER, FUEL (3518) (TF) 3500 - 3514

8D10 FAN DRIVE, ADJUSTABLE (2337) (TF).. 2300 - 2322 8I25 FILTER, FUEL (3519) 3500 - 3516

8D13 FAN DRIVE, ADJUSTABLE (2340). 2300 - 2325 8J1 FILTER, FUEL (3521)

8D14 FAN DRIVE, ADJUSTABLE (2341). 2300 - 2326 (AF,HF). 3500 - 3518

8D16 FAN DRIVE, ADJUSTABLE (2342). 2300 - 2328 8J4 FILTER, FUEL (3523) (AF) 3500 - 3522

8D18 FAN DRIVE, ADJUSTABLE (2343). 2300 - 2330 8J6 FILTER, FUEL (3524) (AF) 3500 - 3524

8D20 FAN DRIVE, ADJUSTABLE (2344). 2300 - 2332 9C18 FILTER, OIL (5901) 5900 - 5902

8D22 FAN DRIVE, ADJUSTABLE (2345). 2300 - 2334 9C23 FILTER, OIL (5914) 5900 - 5908

8D24 FAN DRIVE, ADJUSTABLE (2346). 2300 - 2336 10C17 FITTINGS, CYLINDER BLOCK 9900 - 9904

8E1 FAN DRIVE, ADJUSTABLE (2347). 2300 - 2338 8K7 FITTINGS, CYLINDER BLOCK (4602) 4600 - 4602

8E3 FAN DRIVE, ADJUSTABLE (2348). 2300 - 2340 8K10 FITTINGS, CYLINDER BLOCK (4603) (TF) 4600 - 4606

8E5 FAN DRIVE, ADJUSTABLE (2349). 2300 - 2342 8K13 FITTINGS, CYLINDER BLOCK (4604) (AF) 4600 - 4610

8E7 FAN DRIVE, ADJUSTABLE (2350). 2300 - 2344 1D14 FLYWHEEL (ALLISON TRANSMISSION) (1504)1500 - 1502

8E10 FAN DRIVE, ADJUSTABLE (2352). 2300 - 2347 1D13 FLYWHEEL (1503) 1500 - 1501

8E11 FAN DRIVE, ADJUSTABLE (2353). 2300 - 2348 1D15 FLYWHEEL (1505) 1500 - 1503

8E13 FAN DRIVE, ADJUSTABLE (2355) (TF).. 2300 - 2350 1D16 FLYWHEEL (1506) 1500 - 1504

8E14 FAN DRIVE, ADJUSTABLE (2356) (TF).. 2300 - 2351 1D17 FLYWHEEL (1507) 1500 - 1505

8E15 FAN DRIVE, ADJUSTABLE (2357) (TF).. 2300 - 2352 1D18 FLYWHEEL (1508) 1500 - 1506

8E16 FAN DRIVE, ADJUSTABLE (2359) (TF).. 2300 - 2353 1D19 FLYWHEEL (1510) 1500 - 1507

8E17 FAN DRIVE, ADJUSTABLE (2359) (TF).. 2300 - 2354 1D20 FLYWHEEL (1511) (AF,HF) 1500 - 1508

8C19 FAN DRIVE, FIXED (2305) 2300 - 2306 1D21 FLYWHEEL (1512) 1500 - 1509

8C20 FAN DRIVE, FIXED (2306) 2300 - 2307 1D22 FLYWHEEL (1513) 1500 - 1510

8D3 FAN DRIVE, FIXED (2311) 2300 - 2314 1D23 FLYWHEEL (1526) 1500 - 1511

8D8 FAN DRIVE, FIXED (2335) 2300 - 2320 1D24 FLYWHEEL (1532) 1500 - 1512

8D9 FAN DRIVE, FIXED (2336) 2300 - 2321 1D25 FLYWHEEL (1544) 1500 - 1513

8D11 FAN DRIVE, FIXED (2338) 2300 - 2323 1D5 FLYWHEEL HOUSING (SAE 1) (1401) .. 1400 - 1401

8D12 FAN DRIVE, FIXED (2339) 2300 - 2324 1D8 FLYWHEEL HOUSING (SAE 1) (1408) .. 1400 - 1404

8E9 FAN DRIVE, FIXED (2351) 2300 - 2346 1D6 FLYWHEEL HOUSING (SAE 2) (1402) .. 1400 - 1402

8E12 FAN DRIVE, FIXED (2354) 2300 - 2349 1D7 FLYWHEEL HOUSING (SAE 2) (1405) .. 1400 - 1403

8E18 FAN PULLEY ADJUSTABLE (23AL) 2300 - 2356 1D9 FLYWHEEL HOUSING (SAE 3) (1424) .. 1400 - 1405

8C23 FAN PULLEY ADJUSTABLE (2308) 2300 - 2310 7J4 FLYWHEEL HOUSING COVER (1905) .. 1900 - 1902

8D1 FAN PULLEY ADJUSTABLE (2309) 2300 - 2312 7J6 FLYWHEEL HOUSING COVER (1906) .. 1900 - 1904

8D4 FAN PULLEY ADJUSTABLE (2313) 2300 - 2316 7J9 FLYWHEEL HOUSING COVER (1908) .. 1900 - 1908

8D16 FAN PULLEY ADJUSTABLE (2342) 2300 - 2328 7J12 FLYWHEEL HOUSING COVER (1909) .. 1900 - 1912

8D18 FAN PULLEY ADJUSTABLE (2343) 2300 - 2330 7J15 FLYWHEEL HOUSING COVER (1910) .. 1900 - 1916

8D20 FAN PULLEY ADJUSTABLE (2344) 2300 - 2332 7J18 FLYWHEEL HOUSING COVER (1911) .. 1900 - 1920

8D22 FAN PULLEY ADJUSTABLE (2345) 2300 - 2334 7J21 FLYWHEEL HOUSING COVER (1912) .. 1900 - 1924

8D24 FAN PULLEY ADJUSTABLE (2346) 2300 - 2336 7J24 FLYWHEEL HOUSING COVER (1913) .. 1900 - 1928

8E1 FAN PULLEY ADJUSTABLE (2347) 2300 - 2338 7K1 FLYWHEEL HOUSING COVER (1914) .. 1900 - 1930

8E3 FAN PULLEY ADJUSTABLE (2348) 2300 - 2340 7K4 FLYWHEEL HOUSING COVER (1915) .. 1900 - 1934

8E5 FAN PULLEY ADJUSTABLE (2349) 2300 - 2342 7K7 FLYWHEEL HOUSING COVER (1916) .. 1900 - 1938

8E7 FAN PULLEY ADJUSTABLE (2350) 2300 - 2344 1D10 FLYWHEEL HOUSING, NO (1499). 1400 - 1406

8E11 FAN PULLEY ADJUSTABLE (2353) 2300 - 2348 2D3 FUEL CONTROL LINES (1601) (AF)

8C19 FAN PULLEY FIXED (2305) .. 2300 - 2306 (ESN 068145- ) 1600 - 1610

8C20 FAN PULLEY FIXED (2306) .. 2300 - 2307 2D1 FUEL CONTROL LINES (1601) (TF,HF)

8D3 FAN PULLEY FIXED (2311) .. 2300 - 2314 (ESN (AF) -068144)1600 - 1608

8D9 FAN PULLEY FIXED (2336) .. 2300 - 2321 2D19 FUEL CONTROL LINES (1602) (HF)

8D11 FAN PULLEY, FIXED (2338).. 2300 - 2323 (ESN (AF) 068145- ) 1600 - 1626

9L11 FAN, BLOWER (26", 660MM)(8-BLADE) (9701) 9700 - 9731 2D17 FUEL CONTROL LINES (1602) (TF)

9L10 FAN, BLOWER (28", 711MM)(8-BLADE) (9701) 9700 - 9730 (ESN (AF) -068144) .. 1600 - 1624

9L13 FAN, BLOWER (9701)9700 - 9733 2E12 FUEL CONTROL LINES (1603) (AF,HF) 1600 - 1644

8E12 FAN, PULLEY FIXED (2354).. 2300 - 2349 2E14 FUEL CONTROL LINES (1603) (TF) . 1600 - 1646

8E10 FAN, PULLEY, ADJUSTABLE (2352) . 2300 - 2347 2F7 FUEL CONTROL LINES (1604) (AF,HF) 1600 - 1662

8D12 FAN, PULLEY, FIXED (2339) 2300 - 2324 2F9 FUEL CONTROL LINES (1604) (TF) . 1600 - 1664

8E9 FAN, PULLEY, FIXED (2351) 2300 - 2346 2G1 FUEL CONTROL LINES (1605) (AF) . 1600 - 1680

9L12 FAN, SUCTION (9701) .. 9700 - 9732 2G3 FUEL CONTROL LINES (1605) (TF,HF) 1600 - 1682

9L14 FAN, SUCTION 4 BOLT, 23" (9701) 9700 - 9734 2G22 FUEL CONTROL LINES (1606) (AF)