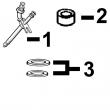

约翰迪尔 6068T/H 6.8T/H 活塞(米)RE55512/RE505102

|

|

|

发动机和设备型号

|

孔径: 4.19 in 106.5 mm

销径 Ø: 1.6250 in (+/- .0002) = 41mm

发动机型号:

6068TF275

6068HF252

6068TF220

6068HF275

6068TF252

6068TF258

6068SFM50

连杆(米):

R114081 (Machined) (13)

R500335 (Fractured) (13)

洋马发动机

Rottne SMV Rapid Forwarder

|

|

|

强鹿JOHN DEERE柴油机配件、发动机配件、发电机组:

RE69781、RE50809、RE64243、RE507959、RE506544、RE504063、SE501235、RE504067、RE547892、AR2643、RE41956、RE539769、RE505475、SE500804、RE522964、AR2643、RE69791、SE501268、EDG-01V-H-1-PNT11-5115-R、A45-F-F-04-Hdpsg,rg40854,711 –19–03aug00–1/1 8.1l - l3 - engine oil pressure high symptom problem solution 8.1l - l3 - engine oil pressure incorrect oil drain crankcase&refill with high proper grade&viscosity oil. see diesel engine oil in section 01, group 002 of this manual. faulty oil pressure sen***/gauge measure engine oil pressure with a mechanical gauge to verify pressure is high. see check engine oil pressure later in this group. faulty oil pressure regulating valve remove&inspect engine oil pressure regulating valve. see remove, inspect,&install oil pressure regulating valve, oil filter bypass valve,&oil cooler bypass valve in section 02, group 060 of this manual. stuck oil filter bypass valve remove&inspect engine oil filter bypass valve. see remove, inspect,&install oil pressure regulating valve, oil filter bypass valve, and oil cooler bypass valve in section 02, group 060 of this manual. stuck oil cooler bypass valve remove&inspect engine oil cooler bypass valve. see remove, inspect,&install oil pressure regulating valve, oil filter bypass valve, and oil cooler bypass valve in section 02, group 060 of this manual. ctm86 (20mar01) 04-150-8 powertech? 8.1 l diesel engines — base engine 032001 pn=370 observable diagnostics&tests 04 150 9 dpsg,rg40854,707 –19–03aug00–1/1 8.1l - c1 - engine coolant temperature above normal symptom problem solution 8.1l - c1 - engine coolant low coolant level add coolant to proper level. temperature above normal plugged radiator core and/or side clean radiator and/or side shields as shields required. engine overloaded reduce engine load. low crankcase oil level fill crankcase to proper level. loose/faulty fan belt replace/tighten fan belt as required. faulty coolant temperature measure coolant temperature with a switch/sen***/coolant temperature gauge of known accuracy to indicator light/gauge determine if coolant temperature is above normal. faulty radiator cap test radiator cap. see pressure test cooling system and radiator cap later in this group. faulty thermostats test thermostat opening temperature. see inspect thermostat&test opening temperature later in this group. faulty cylinder head gasket look for signs of a head gasket failure. see check for head gasket failures later in this group. faulty coolant pump remove&inspect coolant pump. see visually inspect coolant pump&remove coolant pump assembly in section 02, group 070 of this manual. ctm86 (20mar01) 04-150-9 powertech? 8.1 l diesel engines — base engine 032001 pn=371 observable diagnostics&tests 04 150 10 dpsg,rg40854,708 –19–03aug00–1/1 8.1l - c2 - engine coolant temperature below normal symptom problem solution 8.1l - c2 - engine coolant faulty coolant temperature measure coolant temperature with a temperature below normal switch/sen***/coolant temperature gauge of known accuracy to indicator light/gauge determine if coolant temperature is below normal. faulty thermostats test thermostat opening temperature. see inspect thermostat&test opening temperature later in this group. dpsg,rg40854,709 –19–03aug00–1/1 8.1l - c3 - coolant in oil/oil in coolant symptom problem solution 8.1l - c3 - coolant in oil/oil in faulty cylinder head gasket look for signs of a head gasket coolant failure. see check for head gasket failures later in this group. faulty oil cooler remove&inspect engine oil cooler. see remove, inspect, and install engine oil cooler in section 02, group 060 of this manual. leaking cylinder liner seals remove&inspect cylinder liners. see remove cylinder liners in section 02, group 030 of this manual. cracked cylinder head/block locate crack, repair/replace components as required. ctm86 (20mar01) 04-150-10 powertech? 8.1 l diesel engines — base engine 032001 pn=372 observable diagnostics&tests 04 150 11 dpsg,rg40854,2 –19–24nov98–1/2 test engine compression pressure rg4118 –un–27oct88 a—nozzle adapter b—gauge&hose assembly important: compression pressures are affected by the cranking speed of the engine. before beginning the test, ensure that batteries are fully charged&injection nozzle area is thoroughly cleaned. 1. start engine&run at rated speed until it warms up to normal operating temperature. (from a cold start, operate engine 10-15 minutes at slow idle.) 2. remove injection lines, leak-off lines,&injection nozzles. if mechanical fuel system, see remove fuel injection nozzles in group 090 of ctm243. if level 3 electronic fuel system, see remove fuel injection nozzles in group 090 of ctm134. 3. install the jt01675a nozzle adapter&jt01677 adapter nut (a) into injection nozzle bore. tighten adapter nut to 80 n?m (60 lb-ft). 4. connect jt01682 gauge&hose assembly (b) to nozzle adapter. 5. if engine is equipped with an electronic governor, remove battery power supply to the engine control unit (ecu) by removing the ecu power supply fuse, or by disconnecting the ecu from the wiring harness. if engine is equipped with a mechanical governor, disconnect the electrical connection to the fuel shut-off solenoid. 6. crank engine over with starting motor for approximately 10 seconds&record compression readings. compare readings with specifications listed below: specification engine compression pressure—compression pressure 2,380—2,790 kpa (23.8—27.9 bar) (345—405 psi) 黔南强鹿机油滤清器T19044批发,克孜勒苏约翰迪尔强鹿4045发动机内部修理套件供货商,宜昌约翰迪尔强鹿平衡轴轴套批发商,果洛强鹿6068柴油机空气加热器哪家好,南通约翰迪尔挖掘机活塞环价格行情,崇左约翰迪尔联合收割机发动机活塞环哪里买,邵阳强鹿4045柴油机连杆螺丝TR501124多少钱,忻州强鹿6090柴油发动机连杆铜衬套厂家批发,德宏约翰迪尔发动机缸盖公司,池州美国JohnDeere皮带R134636/R503312价格行情,襄阳强鹿柴滤RE520842厂家批发,滁州johndeere约翰迪尔强鹿柴油发动机发动机修理包RE535190找哪家,鹰潭约翰迪尔联合收割机发动机柴油泵诚信推荐,马鞍山约翰迪尔拖拉机发动机活塞销批发商,舟山JohnDeere凸轮轴衬套RE504914厂家供应, ctm86 (20mar01) 04-150-11 powertech? 8.1 l diesel engines — base engine 032001 pn=373 continued on next page observable diagnostics&tests 04 150 12 dpsg,rg40854,2 –19–24nov98–2/2 note: pressure given was taken at 300 m (1000 ft) above sea level. a 3.6% reduction in gauge pressure will result for each additional 300 m (1000 ft) of altitude. all cylinders within an engine should have approximately the same pressure. there should be less than 340 kpa (3.4 bar) (50 psi) difference between cylinders. 7. if pressure is much lower than the specification, remove gauge&apply oil to ring area of piston through injection nozzle bore. do not use too much oil and do not get oil on valves. 8. crank engine over&record compression reading again. ? if pressure is significantly higher than the first compression reading taken, worn/stuck rings are indicated. either replace piston rings/install new piston&liner set as needed. see install cylinder liner in block&install piston and connecting rod§ion 02, group 030 of this manual. ? if pressure remains much lower than the specification, it is possible that valve lash is incorrect or valves are worn/sticking. measure valve lash to specifications/recondition cylinder as needed. see check&adjust valve clearance serial number ( —199,999) in section 02, group 020 of this manual,/see check valve clearance serial number (200,000— ). 9. measure compression pressure in all remaining cylinders&compare readings. recondition power cylinders&cylinder head as required. ctm86 (20mar01) 04-150-12 powertech? 8.1 l diesel engines — base engine 032001 pn=374 observable diagnostics&tests 04 150 13 dpsg,rg40854,4 –19–24nov98–1/1 check engine cranking speed rg9444 –un–23jul98 important: make sure that batteries are fully charged before performing this test. 1. disable the fuel supply system at the injection pump so fuel delivery is in the off position. 2. if not using the machine tachometer, install a photo tachometer. 3. crank engine for 15 seconds&record engine speed. 4. compare recorded engine speed to chart above. cranking speed should meet/exceed specified engine rpm for a given ambient air temperature. for example, at 85°f (29°c) ambient temperature, cranking speed should be at least 200 rpm. if cranking speed is below specifications, check the following: ? starting system problems (low battery, loose or defective wiring, defective starter, etc.) ? excessive engine loads (hydraulic pumps/thick oil, thick engine oil, etc.). ctm86 (20mar01) 04-150-13 powertech? 8.1 l diesel engines — base engine 032001 pn=375 observable diagnostics&tests 04 150 14 dpsg,rg40854,6 –19–24nov98–1/1 check engine oil pressure rg7067 –un–20aug98 1. 舟山约翰迪尔R106796气门室盖垫片代理商,承德约翰迪尔发动机飞轮壳市场报价,嘉兴约翰迪尔柴油机R502511气缸盖螺丝代理,威海约翰迪尔加大止推轴承瓦RE65912哪家买,曲靖强鹿柴油机RE521348曲轴代理,白城johndeere约翰迪尔强鹿柴油机皮带哪家买,蚌埠JohnDeere后油封RE530121公司,钦州JohnDeere连杆RE535555的价格,玉树强鹿柴油发电机组喷油嘴厂家价格,晋中johndeere约翰迪尔强鹿柴油机曲轴瓦供货商,双鸭山JohnDeere缸套阳水圈AR65507公司,六盘水强鹿柴油机手油泵RE38009供应商,攀枝花约翰迪尔柴油发电机组电磁阀价格行情,盐城约翰迪尔强鹿3029柴油机气门锁夹信息,海南约翰迪尔柴油发电机组柴油泵价格行情,永州约翰迪尔机油冷却器AR55394供应商,本溪强鹿机滤RE509672批发,通化约翰迪尔6090柴油机机油底壳垫片一级代理,百色RE62418原装强鹿柴油滤清器诚信推荐,成都强鹿柴油发动机仪表盘价格,黄山强鹿水泵修理包供应商,濮阳约翰迪尔4045柴油机张紧轮RE518097价格行情,check engine crankcase oil level. adjust as necessary. 2. check overall condition of oil (viscosity, presence of coolant, etc.). change engine oil&replace oil filter if necessary. 3. remove pipe plug from main oil gallery using jdg782 oil gallery plug tool. 4. attach pressure gauge to oil galley. important: to achieve an accurate oil pressure reading, warm up engine to 105°c (220°f). 5. start engine, run at speeds given below, measure oil pressure,&compare readings. specification oil pressure specifications—minimum no load at 850 rpm (slow idle) 138 kpa (1.38 bar) (20 psi) maximum full load at 2200 rpm (rated speed) 400 kpa (4.0 bar) (58 psi) 6. refer to “engine oil pressure low” and/or “engine oil pressure high” as detailed under diagnosing engine malfunctions, earlier in this group if oil pressure is not within specification. note: the oil pressure regulating valve is designed so that adjustment of oil pressure should not be required using shims. ctm86 (20mar01) 04-150-14 powertech? 8.1 l diesel engines — base engine 032001 pn=376 observable diagnostics&tests 04 150 15 dpsg,rg40854,7 –19–24nov98–1/1 check for excessive engine crankcase pressure (blow-by) rg9720 –un–04dec98 a—breather tube excessive blow-by coming out of the crankcase breather tube (a) indicates that either the turbocharger seals are faulty/the piston rings&cylinder liners are not adequately sealing off the combustion chamber. this is a comparative check that requires some experience to determine when blow-by is excessive. run engine at high idle&check crankcase breather tube. look for significant fumes and/or dripping oil coming out of the breather tube at fast idle, with no load. if excessive blow-by is observed, perform the following to determine if the turbocharger is causing the blow-by: 1. remove the turbocharger oil drain line where it connects to the engine block&run the line into a ***et. 2. run engine at high idle, slightly loaded&determine if boost pressure is forcing oil through the drain line, and check crankcase breather tube to determine if blow-by has decreased. 3. if it appears that boost pressure is forcing oil through the drain line, and/or blow-by decreases with the drain line disconnected from the block, replace the turbocharger&retest. ctm86 (20mar01) 04-150-15 powertech? 8.1 l diesel engines — base engine 032001 pn=377 observable diagnostics&tests 04 150 16 dpsg,rg40854,8 –19–24nov98–1/1 check for turbocharger oil seal leak rg9730 –un–22jan99 a—intake hose b—exhaust pipe c—oil return line seals are used on both sides of the turbocharger rotor assembly. the seals are used to prevent exhaust gases and air from entering the turbocharger housing. oil leakage past the seals is uncommon but can occur. a restricted/damaged turbocharger oil return line can cause the housing to pressurize causing oil to leak by the seals. additionally, intake/exhaust restrictions can cause a vacuum between the compres*** and turbocharger housing causing oil to leak by the seals. 1. remove intake tube (a)&exhaust pipe (b). note: the intake tube from the air cleaner (not included in picture) would not have to be removed for this test. 2. inspect the intake tube&turbocharger turbine casing for evidence of oil leakage. if oil leakage is present, perform the following: ? inspect turbocharger oil return line (c) for kinks or damage. replace if necessary. ? check the air intake filter, hoses,&crossover tube for restrictions. ? check the exhaust system for restrictions to include position of exhaust outlet. 3. perform necessary repairs&retest. ctm86 (20mar01) 04-150-16 powertech? 8.1 l diesel engines — base engine 032001 pn=378 observable diagnostics&tests 04 150 17 dpsg,rg40854,10 –19–25nov98–1/1 inspect thermostat&test opening temperature rg5971 –un–23nov97 visually inspect thermostat for corrosion/damage. replace as necessary. ? test thermostat as follows: caution: do not allow thermostat or thermometer to rest against the side/bottom of container when heating water. either may rupture if overheated. 1. suspend thermostat&a thermometer in a container of water. 2. stir the water as it heats. observe opening action of thermometer&compare temperatures with specification given in chart below. note: due to varying tolerances of different suppliers, initial opening&full open temperatures may vary slightly from specified temperatures. thermostat test specifications rating initial opening (range) full open (nominal) 71°c (160°f) 69—72°c (156—162°f) 84°c (182°f) 77°c (170°f) 74—78°c (166—172°f) 89°c (192°f) 82°c (180°f) 80—84°c (175—182°f) 94°c (202°f) 89°c (192°f) 86—90°c (187—194°f) 101°c (214°f) 90°c (195°f) 89—93°c (192—199°f) 103°c (218°f) 92°c (197°f) 89—93°c (193—200°f) 105°c (221°f) 96°c (205°f) 94—97°c (201—207°f) 100°c (213°f) 99°c (210°f) 96—100°c (205—212°f) 111°c (232°f) 3. remove thermostat&observe its closing action as it cools. in ambient air the thermostat should close completely. closing action should be smooth&slow. 4. if any thermostat is defective on a multiple thermostat engine, replace all thermostats. ctm86 (20mar01) 04-150-17 powertech? 8.1 l diesel engines — base engine 032001 pn=379 observable diagnostics&tests 04 150 18 dpsg,rg40854,11 –19–25nov98–1/2 pressure test cooling system&radiator cap rg6558 –un–20jan93 rg6557 –un–20jan93 caution: explosive release of fluids from pressurized cooling system can cause serious burns. shut off engine. only remove filler cap when cool enough to touch with bare hands. slowly loosen cap to first stop to relieve pressure before removing completely. test radiator cap: 1. remove radiator cap&attach to d05104st tester as shown. 2. pressurize cap to 50 kpa (0.5 bar) (7 psi)1 . gauge should hold pressure for 10 seconds within normal range if cap is acceptable. 3. remove the cap from gauge, turn it 180°,&retest cap. this will verify that the first measurement was a开封强鹿6068柴油机曲轴一级代理,资阳约翰迪尔柴油发电机组四配套批发,贵港约翰迪尔喷油器O型圈RE530609公司,大连强鹿6081柴油发动机衬垫套厂家批发,自贡JOHNDEERE强鹿4039DF005配件批发价,曲靖强鹿柴油机RE521348曲轴市场报价,兴安强鹿R519488排气歧管垫片一级代理,贵阳约翰迪尔6068柴油机加热器公司,大理约翰迪尔6068柴油机前油封批发商,甘南直销强鹿JOHNDEERE柴油机配件代理,绍兴直销强鹿PE4045发电机配件公司,福州约翰迪尔E360LC挖掘机发动机配件价格,广元强鹿柴油发电机组启动机代理,晋中约翰迪尔曲轴RE504638多少钱,洛阳强鹿AR97708U水泵供货商ccurate. test cooling system: note: engine should be warmed up to test overall cooling system. 1. allow engine to cool, then carefully remove radiator cap. 2. fill radiator with coolant to the normal operating level. important: do not apply excessive pressure to cooling system, doing so may damage radiator&hoses. 3. connect gauge&adapter to radiator filler neck. pressurize cooling system to 50 kpa (0.5 bar) (7 psi)2. 1if gauge does not hold pressure, replace radiator cap. 2 test pressures recommended are for all deere oem cooling systems. on specific vehicle applications, test cooling system&pressure cap according to the recommended pressure for that vehicle. ctm86 (20mar01) 04-150-18 powertech? 8.1 l diesel engines — base engine 032001 pn=380 continued on next page observable diagnostics&tests dpsg,rg40854,11 –19–25nov98–2/2 4. with pressure applied, check all cooling system hose connections, radiator,&overall engine for leaks. if leakage is detected, correct as necessary&pressure test system again. if no leakage is detected, but the gauge indicated a drop in pressure, coolant may be leaking internally within the system/at the block-to head gasket. see check for head gasket failures later in this group. 04 150 19 ctm86 (20mar01) 04-150-19 powertech? 8.1 l diesel engines — base engine 032001 pn=381 observable diagnostics&tests 04 150 20 dpsg,rg40854,12 –19–25nov98–1/4 check for head gasket failures rg6449 –un–26nov97 a—combustion sealing areas b—oil sealing areas (push rod) c—coolant sealing areas d—cylinder head cap screws note: booklet db1119-cylinder head gasket failures for 6466&6076 engines can be used as a guide for diagnosing head gasket failures on powertech? 8.1 l engines. however, use specifications provided in this manual (ctm134). head gasket failures generally fall into three categories: ? combustion seal failures ? coolant seal failures ? oil seal failures combustion seal failures occur when combustion gases escape between cylinder head&head gasket combustion flange,/between combustion flange and cylinder liner. leaking combustion gases may vent to an adjacent cylinder, to a coolant/oil passage, or externally. coolant/oil seal failures occur when oil/coolantKEY PART NO. PART NAME QTY SERIAL NO. F F F REMARKS

1 R67364 ELBOW FITTING 2 X

2 R51936 SEALING WASHER 6 X

3 RE66060 FUEL LINE 1 X (B) (SUB FOR RE63665)

4 R135106 CLAMP 1 X (SUB FOR R70407)

5 R67271 UNION FITTING 1 X

6 19H1731 CAP SCREW 1 X 3/8" X 1"

7 12H304 LOCK WASHER 1 X 3/8"

8 RE503559 FUEL LINE 1 X (SUB FOR RE63664)

9 28H1518 WASHER 1 X 0.493" X 0.675" X 5/16"

10 RE49589 FUEL LINE 1 -087549 X

RE501218 FUEL LINE 1 087550-090585 X (SUB RE504748)

RE504748 FUEL LINE 1 090586- X

11 R76358 O-RING 1 X

12 R121195 CAP SCREW 4 X

13 R121164 GEAR 1 X (SUB FOR R112975, THIS APPLICATION)

14 R67364 ELBOW FITTING 1 -087549 X

RE502650 FITTING 1 087550- X

15 R114130 STUD 4 X (SUB FOR R55396, THIS APPLICATION)

16 M72490 WASHER 4 X

17 14H1090 NUT 4 X 3/8", (SUB FOR E55662, THIS

APPLICATION)

18 RE46375 FUEL PUMP 1 X (ROBERT BOSCH)

19 R67264 PACKING 2 X

20 AR87561 OIL LINE 1 X

21 AR88903 ELBOW FITTING 1 X

22 R79060 O-RING 1 X

23 RE501785 FUEL INJECTION PUMP 1 X (A) (ROBERT BOSCH) (ALSO ORDER R504886

AND (2) 19M8826)

24 R51936 SEALING WASHER 2 X

25 RE44030 OIL LINE 1 X

26 RE502650 FITTING 1 X (SUB FOR R63604)

27 AR87636 TEE FITTING 1 X

.. R83490 FITTING 1 X

(A) "SEE YOUR AUTHORIZED PUMP REPAIR STATION FOR PARTS NOT LISTED"

CONSULTEZ VOTRE REPARATEUR DE POMPE AGREE POUR LES PIECES NON CATALOGUES

NICHT GEZEIGTE TEILE VON PUMPENWERKSTAT BEZIEHEN.

PER LE PARTI NON ELENCATE, RIVOLGETEVI AL CENTRO AUTORIZZATO DI RIPARAZIONE POMPA

CONSULTE CON SU ESTACION AUTORIZADA RE PEPARACIONES DE BOMBA.

RAADGOER MED EN AUTORISERAD PUMPSERVICVERKSTAD BETRAEFFANDE EJ UPPTAGNAKEY PART NO. PART NAME QTY SERIAL NO. F F F REMARKS

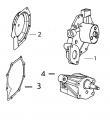

1 R51936 SEALING WASHER 2 X

2 RE504748 FUEL LINE 1 X

3 RE502650 FITTING 1 X

4 R121164 GEAR 1 X

5 R121195 CAP SCREW 4 X

6 R114130 STUD 4 X

7 M72490 WASHER 4 X

8 14H1090 NUT 4 X

9 R79060 O-RING 1 X

10 AR88903 ELBOW FITTING 1 X

11 R67264 PACKING 1 X

12 RE509065 OIL LINE 1 X (SUB FOR RE60577)

13 T18012 ELBOW FITTING 1 X

14 RE505268 FUEL INJECTION PUMP 1 X (A) (BOSCH) (ALSO ORDER R504886 AND (2)

19M8826)

(A) "SEE YOUR AUTHORIZED PUMP REPAIR STATION FOR PARTS NOT LISTED"

CONSULTEZ VOTRE REPARATEUR DE POMPE AGREE POUR LES PIECES NON CATALOGUES

NICHT GEZEIGTE TEILE VON PUMPENWERKSTAT BEZIEHEN.

PER LE PARTI NON ELENCATE, RIVOLGETEVI AL CENTRO AUTOIZZATO DI RIPARAZIONE POMPA

CONSULTE CON SU ESTACION AUTORIZADA RE PEPARACIONES DE BOMBA.

RAADGOER MED EN AUTORISERAD PUMPSERVICICVERKSTAD BETRAEFFANDE EJ UPPTAGNA

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文(简)

中文(简) Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska