详细描述

约翰迪尔饲料/甘蔗收割机应用的发动机零件

设备型号 备注

7500 Liter designated

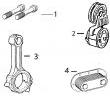

5720 Con Rod (m) R57303, R67320

5720 Con.Rod (m) R71074 (P/N AR93341)

5730 Con.Rod (m) R71074 (P/N AR93341)

5720 Con Rod (m) R71074 (P/N AR93341)

5730 Con Rod (m) R71074 (P/N AR93341)

7500 Liter designated

5720 Con Rod (m) R57303, R67320

5720 Con.Rod (m) R71074 (P/N AR93341)

5730 Con.Rod (m) R71074 (P/N AR93341)

5720 Con Rod (m) R71074 (P/N AR93341)

5730 Con Rod (m) R71074 (P/N AR93341)

约翰迪尔 6068T/H 6.8T/H 活塞(米)RE521616 排放 2 & 3

|

|

||||||||||||||||||||||||||||

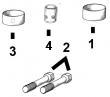

(1)1件组合式密封和穿套; 替换TRE59810,RE538097。

(2)曲轴加工过程中必须保持适当的轴承轴颈半径,以保证正确的操作。

(3)曲轴(m)R116076,直鼻。

(4)曲轴(m)R503470,锥形鼻。

(5)检查应用程序是否正确使用。

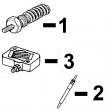

(6)线路连接都是线程化的。

(7)线路连接是一个软管倒钩& 一个线程。

(8)线路连接是两个软管倒钩。

(9)机器分体式和断裂式分体式连杆均可用于同一台发动机,但每个连杆必须使用正确的连杆螺栓。

6068TFM75, 6068TFM76、6068HF275、6125HF070\6125AF001,4039DFM、6125HF070、6135HF475-2、6135HF475-3 RE68345、 RE53307、RE62240、RE533095、RE502513、RE38009、R30402、RE517180、RE530107、RE62240、P524837、RE60021、RE507236、RE59588、RE549153、RE530870、SE501610、SE501609、RE70960、RE533501、RE533608、AR50041、RE515409increases at 20% per minute until full power is reached. note: shutdown only occurs on engines that have the option in their ecu. low fuel pressure protection ? warning: a power derate of 2% per minute with a maximum derate of 20% of rated power will start if the “warning” fault lamp is set. if the fuel pressure increases over the “warning” fault pressure, the power will increase at the rate of 2% per minute until full power is reached. ? shutdown: a power derate of 20% per minute with a maximum derate of 40% of rated power occurs if the fuel supply pressure becomes lower than the “shutdown” fault pressure. if this fault stays on for 30 seconds, the engine will shut down. if the fuel pressure begins to increase above the “shutdown” fault pressure, the “warning” fault will activate. the power derate will revert to the “warning” fault. note: shutdown only occurs on engines that have the option in their ecu. high fuel pressure protection ctm188 (20mar01) 03-140-18 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=136 continued on next page electrical control system operation 03 140 19 dpsg,rg40854,459 –19–14oct99–2/2 ? warning: a power derate of 2% per minute with a maximum derate of 20% of rated power occurs if fuel pressure exceeds the “warning” fault pressure. if the fuel pressure decreases below the “warning” fault pressure, the power will increase at the rate of 2% per minute until full power is reached. wif (water in fuel) protection ? warning: a power derate of 2% per minute with a maximum derate of 20% of rated power will start if the “warning” fault lamp is set. if wif decreases past the “warning” fault pressure, the power will increase at the rate of 2% per minute until full power is reached. ? shutdown: a power derate of 20% per minute with a maximum derate of 40% of rated power occurs if wif exceeds the “shutdown” time limit for this detection. if wif does not decrease below the “shutdown” detection level within 30 seconds, the engine will shut down. if wif decreases below the “shutdown” detection level within 30 seconds, the power derate will divert to the “warning” curve. note: shutdown only occurs on engines that have the option in their ecu. high mat (manifold air temperature) protection ? warning: a power derate of 2% per minute with a maximum derate of 20% of rated power occurs if mat exceeds the “warning” fault temperature. if mat decreases past the “warning” fault pressure, the power will increase at the rate of 2% per minute until full power is reached. air filter restriction protection ? warning: a power derate of 2% per minute with a maximum derate of 20% of rated power will start if the “warning” fault lamp is set. if the air pressure increases over the “warning” fault pressure, the power will increase at the rate of 2% per minute until full power is reached. ctm188 (20mar01) 03-140-19 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=137 electrical control system operation 03 140 20 dpsg,rg40854,460 –19–14oct99–1/1 multiple torque curve selection rg8552 –19–18sep98 torque curves the ecu has the ability to limit the maximum fuel quantity such that multiple torque curves can be individually selected while the engine is running. the selection of multiple torque curves is determined by either switch inputs into the ecu’s torque curve select terminal,/by messages from other controllers on {"state": 10001,"message": "信息添加成功!"}the machine’s controller area network (can). in most applications, one torque curve is used for “normal” operation. several other derated torque curves will be used to protect vehicle axles, hitches,&transmissions, etc. under certain operating conditions. for example: a machine can choose multiple torque curves using simple switching arrangement. a simple on/off toggle switch&resistor can be used to switch between torque curve 1 (maximum power),&any of the other torque curves. when the switch is open, the ecu will command torque curve 1. when the switch is closed, the ecu will command one of the other curves depending on the resistance in the line. see torque curve selection in section 06, group 210 of this manual for torque curve selection specifications. ctm188 (20mar01) 03-140-20 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=138 electrical control system operation 03 140 21 dpsg,rg40854,461 –19–14oct99–1/1 迪庆强鹿凸轮随动件R123565诚信推荐,石家庄强鹿6068柴油机气门弹簧代理,辽阳约翰迪尔发动机缸套公司,日照强鹿滤芯滤清器RE26814B厂家价格,咸宁约翰迪尔6081发动机挺柱铜价格,塔城强鹿气缸垫RE55475信息,运城强鹿6068柴油机连杆铜套找哪家,景德镇强鹿柴油发电机组机油滤芯代理,凉山约翰迪尔6068柴油机活塞销厂家供货,承德强鹿柴油机后油封RE44574价格行情,昌吉迪尔强鹿后油封re530121的价格,凉山约翰迪尔RE27349连杆瓦批发,克孜勒苏强鹿机油滤re518977厂家供应,克孜勒苏约翰迪尔强鹿4045发动机内部修理套件价格行情,governor droop mode selection the electronic control system has the ability to provide two types of governing; all-speed governing and min-max speed governing. when operating in the all-speed governor mode, the engine control unit (ecu) controls the engine speed based on the analog throttle input/the pwm throttle input. when operating in the min-max speed governor mode, the ecu provides the same minimum (low idle) and maximum (fast idle) speed governing as with the all-speed governor. however, in between the minimum and maximum speeds, the analog throttle input or pwm throttle input is used by the ecu to select a fuel quantity. thus, the throttle commands fuel quantity rather than engine speed in the min-max governor mode. the ecu also has the ability to provide two types of droop; normal&isochronous (0% droop). the normal droop gives a drop in engine speed with an increase in load/an increase in engine speed with a decrease in load. when in isochronous, the droop is set at 0%,&there is a no change in engine speed with changing loads until engine’s torque limit is reached. the factory low idle speed is always set for isochronous governing. droop selection is determined by either switch inputs into the ecu’s droop select terminal,/by messages from other controllers on the machine’s controller area network (can). see governor droop mode selection in section 06, group 210 of this manual for governor droop mode specifications. ctm188 (20mar01) 03-140-21 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=139 electrical control system operation 03 140 22 rg,rg34710,1540 –19–30sep97–1/1 engine control unit (ecu) self-diagnosis the engine control unit (ecu) has the ability to detect problems internally&in the electronic control system. this includes determining if any sen*** input voltages are too high/too low. if the ecu detects a problem with the electronic control system, a diagnostic trouble code (dtc) specific to the failed system will be stored in the ecu’s memory. there are two types of dtcs: ? active ? stored active dtcs indicate that the failure is occurring. these type of failures are sometimes called “hard” failures. stored dtcs indicate that a failure has occurred in the past, but is not currently occurring. this type of dtc can be caused by an “intermittent” failure. these could be problems such as a bad connection/a wire intermittently shorting to ground. there are several different methods for displaying both stored&active dtcs from the ecu. note: if the diagnostic scan tool (dst) is used to read a sen*** voltage&calculated value, and there is an active dtc for that sen***, the calculated value for that sen*** will be the “limp home” value&the voltage will be the actual sen*** voltage. use the voltage during diagnostics unless otherwise directed by a diagnostic chart. spn/fmi codes some applications output dtcs according to the j1939 standard as a two part code. the first part is a two to four-digit suspect parameter number (spn) followed by a one/two-digit failure mode identifier (fmi) code. in order to determine the exact failure, both parts (spn&fmi) of the code are needed. this spn identifies the system/the component that has the failure; for example spn 110 indicates a failure in the engine coolant temperature circuit. the fmi identifies the type of failure that has occurred; for example fmi 4 indicates voltage input below normal. combining spn 110 with fmi 4 yields engine coolant temperature input voltage low,/the equivalent of 2-digit trouble code 24. 2-digit codes some john deere applications display dtcs as 2-digit codes read from an on-board display. viewing active/stored spn/fmi codes dtcs can be cleared on the dst/through the diagnostic gauge on the john deere instrument panel. for directions on how to view active codes using the diagnostic gauge, see viewing active dtcs on diagnostic gauge in section 04, group 160. for directions on how to view stored codes on the diagnostic gauge, see viewing stored dtcs on diagnostic gauge in section 04, group 160. clearing stored dtcs stored dtcs can be cleared through the dst or through the diagnostic gauge on the john deere instrument panel. for directions on how to clear stored dtcs, see clearing stored dtcs on diagnostic gauge in section 04, group 160. ctm188 (20mar01) 03-140-22 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=140 section 04 diagnostics contents page page group 150—observable diagnostics&tests level 6 ecu - f5 - excessive fuel about this group of the manual04-150-1 consumption on single rail fuel level 6 ecu - e1 - engine cranks/won’t system 04-150-32 start 04-150-2 level 6 ecu - f6 - fuel in oil on single rail level 6 ecu - e1 - engine cranks/won’t fuel system 04-150-32 start diagnostic procedure 04-150-2 level 6 ecu - d1 - ecu does not level 6 ecu - e2 - engine misfires/runs communicate with dst 04-150-34 04 irregularly 04-150-6 level 6 ecu - e2 - engine misfires/runs 04-150-35 irregularly diagnostic procedure 04-150-6 level 6 ecu - d1 - ecu does not level 6 ecu - e3 - engine does not develop communicate with dst diagnostic full power 04-150-10 procedure 04-150-35 level 6 ecu - e3 - engine does not level 6 ecu - d2 - ecu does not develop full power diagnostic communicate with diagnostic gauge 04-150-38 procedure 04-150-10 04-150-39 level 6 ecu - e4 - engine emits level 6 ecu - d2 - diagnostic gauge excessive white exhaust smoke04-150-14 does not communicate with ecu 04-150-39 level 6 ecu - e4 - engine emits check dual rail fuel supply pressure 04-150-42 excessive white exhaust smoke diagnostic bleed dual rail fuel system04-150-43 procedure 04-150-14 check single rail fuel supply pressure 04-150-44 level 6 ecu - e5 - engine emits bleed single rail fuel system 04-150-45 excessive black/gray exhaust smoke 04-150-16 group 160—trouble code diagnostics&tests level 6 ecu - e5 - engine emits excessive about this group of the manual 04-160-1 black/gray exhaust smoke diagnostic electrical concepts 04-160-1 procedure 04-150-16 electrical circuit malfunctions 04-160-2 level 6 ecu - e6 - engine will not troubleshooting circuit malfunctions 04-160-5 crank 04-150-18 using a digital multimeter 04-160-9 level 6 ecu - e7 - engine idles poorly 04-150-18 engine configuration data parameters on level 6 ecu - e8 - abnormal engine diagnostic gauge 04-160-10 noise 04-150-19 viewing active dtcs on diagnostic level 6 ecu - f1 - dual rail fuel supply gauge 04-160-12 system check 04-150-22 04-150-23 viewing stored dtcs on diagnostic level 6 ecu - f1 - dual rail fuel supply gauge 04-160-12 system check diagnostic procedure 04-150-23 clearing stored dtcs on diagnostic level 6 ecu - f2 - excessive fuel gauge 04-160-13 consumption on a dual rail fuel data parameter description 04-160-14 system 04-150-27 diagnostic scan tool (dst) engine test level 6 ecu - f3 - fuel in oil on a dual rail instructions—cylinder misfire test04-160-16 fuel system 04-150-27 diagnostic scan tool (dst) engine test level 6 ecu - f4 - single rail fuel supply instructions—compression test 04-160-17 system check 04-150-28 diagnostic scan tool (dst) engine test 04-150-29 instructions— cylinder cutout test 04-160-18 level 6 ecu - f4 - single rail fuel diagnostic trouble codes (dtcs)04-160-19 supply system check diagnostic procedure 04-150-29 continued on next page ctm188 (20mar01) 04-1 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=1 contents page page listing of diagnostic trouble codes level 6 ecu - t10 - pwm throttle (dtcs) 04-160-20 abnormal pulse width diagnostic diagnostic procedure 04-160-23 procedure 04-160-63 intermittent fault diagnostics 04-160-24 level 6 ecu - t11 - excavator throttle level 6 ecu - dtc spn 28, 29, 91 fmi reference voltage high04-160-66 3, 4, 8, 9 .04-160-25 04-160-67 level 6 ecu - t1 - multi-state throttle level 6 ecu - t11 - excavator throttle input high 04-160-26 reference voltage high diagnostic 04-160-28 procedure 04-160-67 level 6 ecu - t1 - multi-state throttle level 6 ecu - t12 - excavator throttle input high diagnostic procedure 04-160-28 reference voltage low 04-160-68 level 6 ecu - t2 - multi-state throttle 04-160-69 input low .04-160-30 level 6 ecu - t12 - excavator throttle 04-160-32 reference voltage low diagnostic level 6 ecu - t2 - multi-state throttle procedure 04-160-69 input low diagnostic procedure 04-160-32 level 6 ecu - t13 - excavator throttle level 6 ecu - t3 - analog throttle (a) ground voltage high 04-160-70 04 input high 04-160-34 04-160-71 04-160-35 level 6 ecu - t13 - excavator throttle level 6 ecu - t3 - analog throttle (a) ground voltage high diagnostic input high diagnostic procedure 04-160-35 procedure 04-160-71 level 6 ecu - t4 - analog throttle (a) level 6 ecu - t14 - excavator throttle input low .04-160-38 ground voltage low 04-160-74 04-160-39 04-160-75 level 6 ecu - t4 - analog throttle (a) level 6 ecu - t14 - excavator throttle input low diagnostic procedure 04-160-39 ground voltage low diagnostic level 6 ecu - t5 - analog throttle (b) procedure 04-160-75 input high 04-160-42 level 6 ecu - t15 - excavator throttle input 04-160-43 voltage high 04-160-76 level 6 ecu - t5 - analog throttle (b) 04-160-77 input high diagnostic procedure 04-160-43 level 6 ecu - t15 - excavator throttle level 6 ecu - t6 - analog throttle (b) input voltage high diagnostic input low .04-160-46 procedure 04-160-77 04-160-47 level 6 ecu - t16 - excavator throttle input level 6 ecu - t6 - analog throttle (b) voltage low04-160-78 input low diagnostic procedure 04-160-47 04-160-79 level 6 ecu - t7 - can throttle invalid 04-160-50 level 6 ecu - t16 - excavator throttle 04-160-51 input voltage low diagnostic level 6 ecu - t7 - can throttle invalid procedure 04-160-79 diagnostic procedure04-160-51 level 6 ecu - dtc spn 94 fmi 1 fuel level 6 ecu - t8 - pwm throttle input supply pressure extremely low 04-160-80 high 04-160-54 04-160-81 04-160-55 level 6 ecu - dtc spn 94 fmi 1 fuel level 6 ecu - t8 - pwm throttle input high supply pressure extremely low diagnostic diagnostic procedure04-160-55 procedure 04-160-81 level 6 ecu - t9 - pwm throttle input level 6 ecu - dtc spn 94 fmi 3 fuel low 04-160-58 supply pressure input voltage high 04-160-82 04-160-59 04-160-83 level 6 ecu - t9 - pwm throttle input low level 6 ecu - dtc spn 94 fmi 3 fuel diagnostic procedure04-160-59 supply pressure input voltage high diagnostic level 6 ecu - t10 - pwm throttle abnormal procedure 04-160-83 pulse width 04-160-62 04-160-63 continued on next page ctm188 (20mar01) 04-2 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=2 contents page page level 6 ecu - dtc spn 94 fmi 4 fuel level 6 ecu - dtc spn 100 fmi 1 engine supply pressure input voltage low 04-160-86 oil pressure extremely low diagnostic 04-160-87 procedure 04-160-107 level 6 ecu - dtc spn 94 fmi 4 fuel level 6 ecu - dtc spn 100 fmi 3 supply pressure input voltage low diagnostic engine oil pressure input voltage procedure 04-160-87 high 04-160-108 level 6 ecu - dtc spn 94 fmi 16 fuel 04-160-109 supply pressure moderately high 04-160-90 level 6 ecu - dtc spn 100 fmi 3 engine 04-160-91 oil pressure input voltage high diagnostic level 6 ecu - dtc spn 94 fmi 16 fuel procedure 04-160-109 supply pressure moderately high diagnostic level 6 ecu - dtc spn 100 fmi 4 procedure 04-160-91 engine oil pressure input voltage low 04-160-110 level 6 ecu - dtc spn 94 fmi 18 fuel 04-160-111 04 supply pressure moderately low04-160-92 level 6 ecu - dtc spn 100 fmi 4 engine 04-160-93 oil pressure input voltage low diagnostic level 6 ecu - dtc spn 94 fmi 18 fuel procedure 04-160-111 supply pressure moderately low diagnostic level 6 ecu - dtc spn 100 fmi 18 procedure 04-160-93 engine oil pressure moderately low 04-160-114 level 6 ecu - dtc spn 97 fmi 0 water 04-160-115 in fuel continuously detected 04-160-94 level 6 ecu - dtc spn 100 fmi 18 engine 04-160-95 oil pressure moderately low diagnostic level 6 ecu - dtc spn 97 fmi 0 water procedure 04-160-115 in fuel continuously detected diagnostic level 6 ecu - dtc spn 102 fmi 3 procedure 04-160-95 manifold air pressure input voltage level 6 ecu - dtc spn 97 fmi 3 water high 04-160-116 in fuel signal voltage high 04-160-96 04-160-117 04-160-97 level 6 ecu - dtc spn 102 fmi 3 manifold level 6 ecu - dtc spn 97 fmi 3 water air pressure input voltage high diagnostic in fuel signal voltage high diagnostic procedure 04-160-117 procedure 04-160-97 level 6 ecu - dtc spn 102 fmi 4 level 6 ecu - dtc spn 97 fmi 4 water manifold air pressure input voltage in fuel signal voltage low 04-160-100 low 04-160-120 04-160-101 04-160-121 level 6 ecu - dtc spn 97 fmi 4 water level 6 ecu - dtc spn 102 fmi 4 manifold in fuel signal voltage low diagnostic air pressure input voltage low diagnostic procedure 04-160-101 procedure 04-160-121 level 6 ecu - dtc spn 105 fmi 3 level 6 ecu - dtc spn 97 fmi 16 water in manifold air temperature input voltage fuel detected 04-160-102 high 04-160-124 04-160-103 04-160-125 level 6 ecu - dtc spn 97 fmi 16 water level 6 ecu - dtc spn 105 fmi 3 manifold in fuel detected diagnostic air temperature input voltage high diagnostic procedure 04-160-103 procedure 04-160-125 level 6 ecu - dtc spn 97 fmi 31 water in level 6 ecu - dtc spn 105 fmi 4 fuel detected 04-160-104 manifold air temperature input voltage 04-160-105 low 04-160-128 level 6 ecu - dtc spn 97 fmi 31 water 04-160-129 in fuel detected diagnostic level 6 ecu - dtc spn 105 fmi 4 manifold procedure 04-160-105 air temperature input voltage low diagnostic level 6 ecu - dtc spn 100 fmi 1 procedure 04-160-129 engine oil pressure extremely low04-160-106 04-160-107 continued on next page ctm188 (20mar01) 04-3 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=3 contents page page level 6 ecu - dtc spn 105 fmi 16 level 6 ecu - dtc spn 111 fmi 1 manifold air temperature moderately engine coolant level low diagnostic high 04-160-130 procedure 04-160-147 04-160-131 level 6 ecu - dtc spn 158 fmi 17 ecu level 6 ecu - dtc spn 105 fmi 16 power down error 04-160-148 manifold air temperature moderately high 04-160-149 diagnostic procedure04-160-131 level 6 ecu - dtc spn 158 fmi 17 ecu level 6 ecu - dtc spn 107 fmi 31 air power down error diagnostic filter restriction high 04-160-132 procedure 04-160-149 04-160-133 level 6 ecu - dtc spn 174 fmi 3 fuel level 6 ecu - dtc spn 107 fmi 31 air temperature input voltage high 04-160-150 filter restriction high diagnostic 04-160-151 procedure 04-160-133 level 6 ecu - dtc spn 174 fmi 3 fuel level 6 ecu - dtc spn 110 fmi 0 temperature input voltage high diagnostic engine coolant temperature high most procedure 04-160-151 severe 04-160-134 level 6 ecu - dtc spn 174 fmi 4 fuel 04 04-160-135 temperature input voltage low04-160-154 level 6 ecu - dtc spn 110 fmi 0 engine 04-160-155 coolant temperature high most severe diagnostic level 6 ecu - dtc spn 174 fmi 4 fuel procedure 04-160-135 temperature input voltage low diagnostic level 6 ecu - dtc spn 110 fmi 3 procedure 04-160-155 engine coolant temperature input voltage level 6 ecu - dtc spn 611 fmi 3 high 04-160-136 injector wiring shorted to power 04-160-137 source 04-160-156 level 6 ecu - dtc spn 110 fmi 3 engine 04-160-157 coolant temperature input voltage high diagnostic level 6 ecu - dtc spn 611 fmi 3 injector procedure 04-160-137 wiring shorted to power source diagnostic level 6 ecu - dtc spn 110 fmi 4 procedure 04-160-157 engine coolant temperature input voltage level 6 ecu - dtc spn 611 fmi 4 low 04-160-140 injector wiring shorted to ground 04-160-160 04-160-141 04-160-161 level 6 ecu - dtc spn 110 fmi 4 engine level 6 ecu - dtc spn 611 fmi 4 coolant temperature input voltage low diagnostic injector wiring shorted to ground diagnostic procedure 04-160-141 procedure 04-160-161 level 6 ecu - dtc spn 110 fmi 15 level 6 ecu - dtc spn 620 fmi 3 engine coolant temperature high least sen*** supply voltage high 04-160-164 severe 04-160-142 04-160-165 04-160-143 level 6 ecu - dtc spn 620 fmi 3 level 6 ecu - dtc spn 110 fmi 15 engine sen*** supply voltage high diagnostic coolant temperature high least severe diagnostic procedure 04-160-165 procedure 04-160-143 level 6 ecu - dtc spn 620 fmi 4 level 6 ecu - dtc spn 110 fmi 16 sen*** supply voltage low04-160-166 engine coolant temperature high moderately 04-160-167 severe 04-160-144 level 6 ecu - dtc spn 620 fmi 4 04-160-145 sen*** supply voltage low diagnostic level 6 ecu - dtc spn 110 fmi 16 engine procedure 04-160-167 coolant temperature high moderately level 6 ecu - dtc spn 627 fmi 1 severe diagnostic procedure04-160-145 injector supply voltage problem 04-160-170 level 6 ecu - dtc spn 111 fmi 1 04-160-171 engine coolant level low 04-160-146 04-160-147 continued on next page ctm188 (20mar01) 04-4 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=4 contents page page level 6 ecu - dtc spn 627 fmi 1 level 6 ecu - dtc spn 651 fmi 5 injector supply voltage problem diagnostic cylinder #1 eui circuit open04-160-204 procedure 04-160-171 04-160-205 level 6 ecu - dtc spn 629 fmi 12/13 level 6 ecu - dtc spn 651 fmi 5 ecu error 04-160-174 cylinder #1 eui circuit open diagnostic 04-160-175 procedure 04-160-205 level 6 ecu - dtc spn 629 fmi 12/level 6 ecu - dtc spn 651 fmi 6 13 ecu error diagnostic procedure 04-160-175 cylinder #1 eui circuit shorted 04-160-208 level 6 ecu - dtc spn 636 fmi 2 cam 04-160-209 position input noise04-160-176 level 6 ecu - dtc spn 651 fmi 6 04-160-177 cylinder #1 eui circuit shorted diagnostic level 6 ecu - dtc spn 636 fmi 2 cam procedure 04-160-209 position input noise diagnostic level 6 ecu - dtc spn 652 fmi 5 procedure 04-160-177 cylinder #2 eui circuit open04-160-212 04 level 6 ecu - dtc spn 636 fmi 8 cam 04-160-213 position input missing 04-160-178 level 6 ecu - dtc spn 652 fmi 5 04-160-179 cylinder #2 eui circuit open diagnostic level 6 ecu - dtc spn 636 fmi 8 cam procedure 04-160-213 position input missing diagnostic level 6 ecu - dtc spn 652 fmi 6 procedure 04-160-179 cylinder #2 eui circuit shorted 04-160-216 level 6 ecu - dtc spn 636 fmi 10 cam 04-160-217 position input pattern error 04-160-182 level 6 ecu - dtc spn 652 fmi 6 04-160-183 cylinder #2 eui circuit shorted diagnostic level 6 ecu - dtc spn 636 fmi 10 cam procedure 04-160-217 position input pattern error diagnostic level 6 ecu - dtc spn 653 fmi 5 procedure 04-160-183 cylinder #3 eui circuit open04-160-220 level 6 ecu - dtc spn 637 fmi 2 crank 04-160-221 position input noise04-160-186 level 6 ecu - dtc spn 653 fmi 5 04-160-187 cylinder #3 eui circuit open diagnostic level 6 ecu - dtc spn 637 fmi 2 crank procedure 04-160-221 position input noise diagnostic level 6 ecu - dtc spn 653 fmi 6 procedure 04-160-187 cylinder #3 eui circuit shorted 04-160-224 04-160-188 04-160-225 level 6 ecu - dtc spn 637 fmi 7 crank level 6 ecu - dtc spn 653 fmi 6 position/cam position out of sync diagnostic cylinder #3 eui circuit shorted diagnostic procedure 04-160-190 procedure 04-160-225 level 6 ecu - dtc spn 637 fmi 8 crank level 6 ecu - dtc spn 654 fmi 5 position input missing 04-160-194 cylinder #4 eui circuit open04-160-228 04-160-195 04-160-229 level 6 ecu - dtc spn 637 fmi 8 crank level 6 ecu - dtc spn 654 fmi 5 position input missing diagnostic cylinder #4 eui circuit open diagnostic procedure 04-160-195 procedure 04-160-229 level 6 ecu - dtc spn 637 fmi 10 level 6 ecu - dtc spn 654 fmi 6 crank position input pattern error 04-160-198 cylinder #4 eui circuit shorted 04-160-232 04-160-199 04-160-233 level 6 ecu - dtc spn 637 fmi 10 level 6 ecu - dtc spn 654 fmi 6 crank position input pattern error diagnostic cylinder #4 eui circuit shorted diagnostic procedure 04-160-199 procedure 04-160-233 level 6 ecu - dtc spn 639 fmi 13 can level 6 ecu - dtc spn 655 fmi 5 error 04-160-202 cylinder #5 eui circuit open04-160-236 04-160-203 04-160-237 level 6 ecu - dtc spn 639 fmi 13 can error diagnostic procedure 04-160-203 continued on next page ctm188 (20mar01) 04-5 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=5 contents page level 6 ecu - dtc spn 655 fmi 5 cylinder #5 eui circuit open diagnostic procedure 04-160-237 level 6 ecu - dtc spn 655 fmi 6 cylinder #5 eui circuit shorted 04-160-240 04-160-241 level 6 ecu - dtc spn 655 fmi 6 cylinder #5 eui circuit shorted diagnostic procedure 04-160-241 level 6 ecu - dtc spn 656 fmi 5 cylinder #6 eui circuit open04-160-244 04-160-245 level 6 ecu - dtc spn 656 fmi 5 cylinder #6 eui circuit open diagnostic procedure 04-160-245 level 6 ecu - dtc spn 656 fmi 6 cylinder #6 eui circuit shorted 04-160-248 04 04-160-249 level 6 ecu - dtc spn 656 fmi 6 cylinder #6 eui circuit shorted diagnostic procedure 04-160-249 level 6 ecu - dtc spn 970 fmi 2 auxiliary engine shutdown switch signal invalid 04-160-252 04-160-253 level 6 ecu - dtc spn 970 fmi 2 auxiliary engine shutdown switch signal invalid diagnostic procedure 04-160-253 level 6 ecu - dtc spn 970 fmi 31 auxiliary engine shutdown switch active 04-160-256 level 6 ecu - dtc spn 971 fmi 31 external fuel derate switch active 04-160-258 level 6 ecu - dtc spn 1109 fmi 31 engine shutdown warning04-160-259 level 6 ecu - dtc spn 1110 fmi 31 engine shutdown04-160-260 level 6 ecu - dtc spn 1569 fmi 31 fuel derate 04-160-261 ctm188 (20mar01) 04-6 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=6 group 150 observable diagnostics&tests 04 150 1 dpsg,rg40854,323 –19–20dec00–1/1 about this group of the manual this group of the manual contains necessary information for observable diagnostics&fuel-related test procedures. use this information in conjunction with the 10.5 l & 12.5 l diesel engines base engine manual (ctm 100). group 150 is divided into two areas: diagnosing malfunctions&test procedures. the diagnosing malfunctions area is further divided into the following headings, containing the following observable symptoms: ? (e) diagnosing general engine malfunctions: – e1 - engine cranks/won’t start – e2 - engine misfires/runs irregularly – e3 - engine does not develop full power – e4 - engine emits excessive white exhaust smoke – e5 - engine emits excessive black/gray exhaust smoke – e6 - engine will not crank – e7 - engine idles poorly – e8 - abnormal engine noise ? (f) diagnosing low pressure fuel system malfunctions – f1 - dual rail fuel supply system check – f2 - excessive fuel consumption on a dual rail fuel system – f3 - fuel in oil on a dual rail fuel system – f4 - single rail fuel supply system check – f5 - excessive fuel consumption on a single rail fuel system – f6 - fuel in oil on a single rail fuel system ? (d) diagnosing diagnostic scan tool (dst) communication malfunctions: – d1 - ecu does not communicate with dst – d2 - ecu does not communicate with diagnostic gauge procedures for diagnosing some of the above symptoms are formatted such that a test/repair is recommended, then based on the results another test or repair is recommended. other symptoms are formatted in a symptom - problem - solution format. in these symptoms, the problems are arranged in the most likely/easiest to check first. symptoms arranged in both formats refer to testing procedures in the second part of this section. the second part of this section of the manual contains the following testing procedures: ? fuel system testing procedures: – check dual rail fuel supply pressure – bleed the dual rail fuel system – check single rail fuel supply pressure – bleed the single rail fuel system ctm188 (20mar01) 04-150-1 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=143 observable diagnostics&tests dpsg,rg40854,327 –19–21nov00–1/1 level 6 ecu - e1 - engine cranks/won’t start – – –1/1 level 6 ecu - e1 - engine cranks/won’t start diagnostic procedure 04 150 2 – – –1/1 1 e1 - preliminary check before using this diagnostic chart: 1. ensure that fuel quality&quantity are ok 2. ensure that engine cranking speed is ok 3. ensure that oil viscosity is correct no problems found: go to 2 problem found: repair&retest – – –1/1 2 active dtc test 1. crank engine for 15 seconds 2. using the dst, monitor dtcs on the active code display parameter no active dtcs present: go to 3 active dtc(s) present: diagnose active dtcs first. if any of the dtcs have a spn of 636/637, go to those first. ecu will not communicate with dst: see d1 - ecu does not communicate with dst in this group. ctm188 (20mar01) 04-150-2 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=144 observable diagnostics&tests – – –1/1 3 cam&crank indicators test 1. start cranking engine 2. using the dst, observe cam noise, crank noise,&crank status while cranking. monitorcam/crank parameters. note: for an explanation of these parameters see data parameter description in group 160. no cam/crank noise and crank status reaches 15: go to 5 cam/crank noise or crank status does not reach 15: go to 4 04 150 3 – – –1/1 4 vehicle wiring inspection check inspect the vehicle for possible failures that can cause either of these conditions: . 1. bad electrical connections 2. damaged camshaft/crankshaft sen*** 3. damaged camshaft/crank timing ring 4. emi from improperly installed radio equipment,/other electronic devices. 5. once the problem is found, repair&retest. – – –1/1 5 fuel hand primer test 1. ignition off 2. operate the hand primer pump located on the fuel filter base until moderate resistance is felt 3. try to start engine engine starts: go to 7 engine does not start: go to 6 – – –1/1 6 pilot injection test while cranking the engine, read the pilot injection parameter on the dst. pilot injection reads on or n/a: go to 6 pilot injection reads off: pilot injection should be on if the ect is below 35°c (95°f). if pilot injection is off under this condition, determine problem in the ect sen*** circuit. ctm188 (20mar01) 04-150-3 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=145 observable diagnostics&tests – – –1/1 7 fuel supply system check check the fuel supply system. ? for dual rail fuel systems, see f1 - dual rail fuel supply system check in this group. ? for single rail fuel systems, see f4 - single rail fuel supply system check in this group. fuel supply system ok: go to 8 fuel supply system problem found: repair fuel supply system problem&retest. 04 150 4 – – –1/1 8 eui cap screw and eui harness and connector test 1. ignition off 2. remove rocker arm cover note: rocker arm cover gasket is reusable if no visible damage is detected. do not store cover resting on gasket surface. 3. check eui rocker arms, valve rocker arms,&camshaft operation. 4. check that the hold down clamp cap screws on all euis are tightened to specification. ? for dual rail fuel systems, see remove&install electronic unit injectors (dual rail fuel systems) in section 02, group 090. ? for single rail fuel systems, see remove&install electronic unit injectors (single rail fuel systems) in section 02, group 091. 5. inspect eui harness&eui harness connector for damage. all components operating correctly: go to 9 faulty component found: repair faulty component and retest. – – –1/1 9 cam to crank timing test verify cam/crank timing is correct. see check&adjust camshaft-to-crankshaft timing in ctm100, section 02, group 050. cam/crank timing ok: replace ecu&retest. cam/crank timing not ok: see check and adjust camshaft-to-crankshaft timing in ctm100, section 02, group 050. ctm188 (20mar01) 04-150-4 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=146 observable diagnostics&tests 04 150 5 ctm188 (20mar01) 04-150-5 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=147 observable diagnostics&tests dpsg,rg40854,330 –19–21nov00–1/1 level 6 ecu - e2 - engine misfires/runs irregularly – – –1/1 level 6 ecu - e2 - engine misfires/runs irregularly diagnostic procedure 04 150 6 – – –1/1 1 e2 - preliminary check before using this diagnostic chart, check for the following that could cause/be mistaken as miss/rough running: 1. intake manifold air leaks 2. engine mechanical problems 3. transmission problems 4. engine acces***ies, such as a/c, cycling on&off 5. electromagnetic interference (emi) from improperly installed radios etc. no problems found: go to 2 problem found: repair and retest. – – –1/1 2 active dtc test 1. ignition on, engine idling 2. using the dst, monitor dtcs on the active code display parameter no active dtcs: go to 3 active dtcs present: diagnose active dtcs first. if any of the dtcs have an spn of 636/637, diagnose those first. – – –1/1 3 engine performance check 1. ignition on, engine idling 2. observe engine performance. not running rough: go to 4 running rough: go to 6 ctm188 (20mar01) 04-150-6 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=148 observable diagnostics&tests – – –1/1 4 recreate conditions operate engine under conditions where the miss/rough running complaint occurs. not running rough: no problem found, verify complaint&try to reproduce conditions of miss/rough running complaint. running rough: go to 5 04 150 7 – – –1/1 5 active dtc test with engine running rough using the dst, monitor dtcs on the active code display parameter no active dtcs: go to 6 active dtcs present: diagnose active dtcs first. if any of the dtcs have an spn of 636/637, diagnose those first. ctm188 (20mar01) 04-150-7 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=149 observable diagnostics&tests 04 150 8 – – –1/1 6 compression and misfire test 1. using the dst, perform the compression test. for instructions, see dst engine test instructions - compression test in group 160. 2. make note of the results. 3. using the dst, perform the engine misfire test. for instructions, see dst engine test instructions - cylinder misfire test in group 160. 4. make note of the results. all cylinders scored within 10% of each other on both tests: go to 7 one/more cylinders scored 10%/more lower than the rest on the compression test and different cylinder(s) scored 10% or more lower on the misfire test: go to 8 one/more cylinders scored 10%/more lower than the rest on the compression test and the same cylinder(s) scored 10% or more lower on the misfire test: go to 9 all cylinders scored within 10% of each other on the compression test and one/more cylinders scored 10%/lower than the rest on the misfire test: go to 10 – – –1/1 7 fuel supply system check check the fuel supply system. ? for dual rail fuel systems, see f1 - dual rail fuel supply system check in this group. ? for single rail fuel systems, see f4 - single rail fuel supply system check in this group. fuel supply system is ok: go to 11 fuel supply system problem found: repair fuel supply system problem&retest – – –1/1 8 inconclusive test results these types of results indicate either the misfire test/the compression test could not operate correctly. further engine diagnostics should be performed to determine if the engine misfire is caused by a faulty eui/by a compression problem. ctm188 (20mar01) 04-150-8 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=150 observable diagnostics&tests – – –1/1 9 low compression pressure check determine the cause of low compression pressure on the low scoring cylinders. – – –1/1 10 suspected eui(s) pre-load adjustment check 1. check eui pre-load adjustment on the eui(s) of the cylinder(s) that tested low on the misfire test. see check&adjust valve assembly clearances and injector preload in section 02, group 020 of ctm100 2. if eui pre-load is adjusted properly, replace the eui(s) of the cylinder(s) that tested low on the misfire test. 04 150 9 – – –1/1 11 eui&valve adjustment test check eui pre-load adjustment&check valve adjustment. see check and adjust valve assembly clearances&injector preload in section 02, group 020 of ctm100. euis&valves properly adjusted: go to 12 euis&valves not properly adjusted: adjust euis&valves to specification&retest. see check and adjust valve assembly clearances and injector preload in section 02, group 020 of ctm100. – – –1/1 12 verification check 1. ensure there are no engine mechanical problems 2. ensure there is not something drawing excessive engine power 3. if none of the above problems are found, see e3 - engine does not develop full power in this group. ctm188 (20mar01) 04-150-9 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=151 observable diagnostics&tests dpsg,rg40854,333 –19–21nov00–1/1 level 6 ecu - e3 - engine does not develop full power – – –1/1 level 6 ecu - e3 - engine does not develop full power diagnostic procedure 04 150 10 – – –1/1 1 e3 - preliminary check before using this diagnostic chart, ensure that: 1. there are no problems with transmission 2. there are no engine mechanical problems 3. there is not an excessive load on the engine 4. there is no unbalanced ballast 5. the air&fuel filters are not restricted/plugged 6. fuel quality is ok problem not found: go to 2 problem found: repair and retest – – –1/1 2 intermittent fault test using the dst, monitor dtcs on the active code display parameter. note: look for dtcs that indicate a fuel derate is/has been in effect. no dtcs present: go to 3 dtcs present: go to appropriate diagnostic procedure. – – –1/1 3 exhaust emission check 1. operate engine at full load rated speed 2. under these conditions, determine type of exhaust emitted. small amount/no exhaust smoke: go to 4 heavy white exhaust smoke: see e4 - engine emits excessive white exhaust smoke diagnostic procedure later in this group. heavy black/gray exhaust smoke: see e5 - engine emits excessive black or gray exhaust smoke diagnostic procedure later in this group. ctm188 (20mar01) 04-150-10 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=152 observable diagnostics&tests 04 150 11 – – –1/1 4 torque curve selection check note: 6750/6850 self-propelled forage harvester applications only use one torque curve; therefore, this check is not required. the ecu on engines has the ability to operate on multiple torque curves. to check that the engine is operating on the correct torque curve under the operating conditions where there is a low power complaint: 1. recreate the conditions of the low power complaint. 2. using the dst, read the torque curve parameter 3. compare the torque curve number with the one shown in torque curve selection in section 06, group 210. the torque curve number displayed is correct for the operating conditions of the low power complaint: go to 5 the torque curve number displayed is not correct for the operating conditions of the low power complaint: refer to machine manual to determine components that if faulty could prevent the correct torque curve from being selected or faulty torque curve select wiring – – –1/1 5 governor droop mode selection check 1. operate engine&attempt to recreate the low power condition. 2. using the dst, read the desired speed governor parameter&the maximum speed governor parameter 3. compare governor selection to the appropriate chart governor mode chart. see governor droop mode selection in section 06, group 210. governor selection is correct: go to 6 governor selection重庆约翰迪尔RE30250批发价,宝鸡约翰迪尔4045柴油机预热塞批发价,安阳约翰迪尔柱塞2455-512厂家供应,咸宁强鹿柴油机发电机皮带R503312一级代理,肇庆约翰迪尔高压油泵市场报价,海口约翰迪尔6081发动机水泵O型圈信息,吉安约翰迪尔6081柴油机排气门导管哪里买,和田强鹿RE27358连杆瓦供应商,鹰潭强鹿柴油机缸垫R116516批发,吴忠强鹿原装进口汽缸垫代理, is incorrect: refer to machine manual to determine components that if faulty could prevent the correct governor from being selected. or faulty governor select wiring. – – –1/1 6 compression and misfire test 1. using the dst, perform the compression test. for instructions, see dst engine test instructions - compression test in group 160. 2. make note of the results. 3. using the dst, perform the engine misfire test. for instructions, see dst engine test instructions - cylinder misfire test in group 160. 4. make note of the results. all cylinders scored within 10% of each other on both tests: go to 7 one/more cylinders scored 10%/more lower than the rest on either test: go to e2 - engine misfires/runs irregularly in this group. ctm188 (20mar01) 04-150-11 powertech 10.5 l & 12.5 l level 6 fuel system 032001 pn=153 observable diagnostics&tests – – –1/1 7 throttle test 1. operate engine at full load rated speed 2. at these operating conditions, read the percent throttle data parameter in the dst. 97%/above: go to 8 below 97%: refer to machine manual andKEY PART NO. PART NAME QTY SERIAL NO. F F F REMARKS

1 RE65265 HAND PRIMER 1 X (SUB FOR RE48048)

2 R54025 WASHER 1 X

3 R26448 O-RING 2 X

4 RE34128 ELBOW FITTING 1 X (A)

RE10258 ELBOW FITTING 1 X (B)

5 R67879 GASKET 1 X

6 RE46252 FUEL PUMP 1 X (ROBERT BOSCH)

7 R93008 WASHER NA X

8 R83489 FITTING NA X

(A) INLET (B) OUTLET

ENTREE SORTIE

EINLASS AUSCLASSE

ENTRATA USCITA

ENTRADA SALIDA

INLOPP UTLOPP

KEY PART NO. PART NAME QTY SERIAL NO. F F F REMARKS

1 RE507268 FUEL LINE 1 X NO. 6

2 RE507267 FUEL LINE 1 X NO. 5

3 RE507266 FUEL LINE 1 X NO. 4

4 RE507265 FUEL LINE 1 X NO. 3

5 R120185 BOLT 4 X

R120181 STRAP 4 X

R120182 STRAP 4 X

R58186 CLAMP 4 X

6 RE507264 FUEL LINE 1 X NO. 2

7 RE507263 FUEL LINE 1 X NO. 1

8 R71212 CLAMP 1 X

R59297 HALF CLAMP 2 X

R120186 BOLT 2 X

R120183 STRAP 1 X

R120184 STRAP 1 X

9 R71212 CLAMP 1 X

R59297 HALF CLAMP 2 X

R120186 BOLT 2 X

R120183 STRAP 1 X

R120184 STRAP 1 X

R120186 BOLT 2 X

10 RE55662 ABSORBER 1 X

11 R59297 HALF CLAMP 2 X

R120185 BOLT 1 X

R120183 STRAP 2 X

12 24H1884 WASHER 1 X 13/32" X 13/16" X 0.120" 13/32" X

13/16" X 0.120"

13 19M7166 CAP SCREW 1 X M10 X 20

14 RE64265 INJECTION NOZZLE 6 X (A) (DENSO)

15 R84472 WASHER 6 X 7.360 X 18.160 X 2 MM (0.290" X 0.715"

X 0.079") 7.360 X 18.160 X 2 MM

(0.290" X 0.715" X 0.079")

16 RE500803 FUEL LINE 1 X

17 AR85519 PLUG 1 X

18 R51937 TUBE NUT 1 X

19 R79604 TUBE NUT 6 X

20 R504057 O-RING 6 X (SUB FOR T44604)

21 RE501970 ADAPTER 6 X

22 RE71255 PIPE PLUG 1 X

(A) 1 RED RING

KEY PART NO. PART NAME QTY SERIAL NO. F F F REMARKS

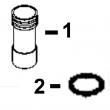

1 R68035 NUT 1 X

2 R69089 O-RING 1 X

3 R115369 NOZZLE HOLDER 1 X

4 R68036 SHIM AR X 0.70MM (.028")

R90544 SHIM AR X 0.725MM (.0285")

R68037 SHIM AR X 0.75MM (.030")

R90543 WASHER AR X 0.775MM (.0305")

R68038 WASHER AR X 0.80MM (.032")

R90542 WASHER AR X 0.825MM (.0324")

R68039 WASHER AR X 0.85MM (.034")

R90541 WASHER AR X 0.875MM (.0344")

R68040 WASHER AR X 0.90MM (.035")

R90540 WASHER AR X 0.925MM (.0364")

R68041 WASHER AR X 0.95MM (.037")

R90539 WASHER AR X 0.0975MM (.0383")

R68042 WASHER AR X 1.00MM (.039")

R90538 WASHER AR X 1.025MM (.0403")

R68043 WASHER AR X 1.05MM (.041")

R90537 WASHER AR X 1.075MM (.0423")

R68044 WASHER AR X 1.10MM (.043")

R90536 WASHER AR X 1.125MM (.0443")

R68045 WASHER AR X 1.15MM (.045")

R90535 WASHER AR X 1.175MM (.0462")

R68046 WASHER AR X 1.20MM (.047")

R90534 WASHER AR X 1.225MM (.0482")

R68047 WASHER AR X 1.25MM (.049")

R90533 WASHER AR X 1.275MM (.0502")

R68048 WASHER AR X 1.30MM (.051")

R90532 WASHER AR X 1.325MM (.0522")

R68049 WASHER AR X 1.35MM (.053")

R90531 WASHER AR X 1.375MM (.0541")

R68050 WASHER AR X 1.40MM (.055")

R90530 WASHER AR X 1.425MM (.0561")

R68051 WASHER AR X 1.45MM (.057")

R90529 WASHER AR X 1.475MM (.0580")

R68052 WASHER AR X 1.50MM (.059")

5 R115368 SPRING 1 X

6 R94410 SEAT 1 X

7 R94412 PLATE 1 X

8 RE64266 NOZZLE 1 X (7 X 0.210)

9 R127176 NUT 1 X

10 R84472 WASHER 1 X

11 RE64265 INJECTION NOZZLE 6 X (A) (DENSO)

免费热线

400-100-8969 15088860848

400-100-8969 15088860848

机组销售

0574-26871589 15267810868

0574-26871589 15267810868

配件销售

0574-26886646 15706865167

0574-26886646 15706865167

维修热线

0574-26871569 18658287286

0574-26871569 18658287286

手机端

微信公众号

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文(简)

中文(简) Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska