详细描述

约翰迪尔农用拖拉机应用的发动机零件

设备型号 备注

5600 Liter designated, Con Rod (m): R80034, Piston (m): RE30250, RE18697

3420 O'rings on block, Con Rod (m): T20007, R81410, Piston (m): T23481

6603 Piston (m) RE59277, RE505100

2020 O'rings on liner, Con Rod (m): RE19733 (SUB FOR AT18005), To ESN 158,257

2510 O'rings on liner, Con Rod (m): RE19733 (SUB FOR AT18005), To ESN 158,257

3120 Small pin, O'rings on liner, Con Rod (m): T20007, R81410, Piston (m): RE53265, T30015, R51451, AR78310

3020 Block (m) R46350, R46430, R40910

8630 Early, Con Rod (m): R66925, R57484

4010 Block (m) R26070, R33180, R34340, R40890, R40900

4020 Block (m) R26070, R33180, R34340, R40890, R40900

820 O'rings on liner, Con Rod (m): T20007 R81410

1020 O'rings on liner, Con Rod (m): T20007 R81410

1030 O'rings on liner, Con Rod (m): T20007 R81410

4430 From ESN 335,846, Block (m): R49470, R49650, R59850, R72128, R87558

4630 From ESN 335,846, Block (m): R49470, R49650, R59850, R72128, R87558

5440 From ESN 335,846, Block (m): R49470, R49650, R59850, R72128, R87558

5400 Piston (m) RE500211

5400N Piston (m) RE500211

1530 Large pin, O'rings on block, Con Rod (m): RE19733 (SUB FOR AT18005), From ESN 179,602

2040 Large pin, O'rings on block, Con Rod (m): RE19733 (SUB FOR AT18005), From ESN 179,602

2330 Large pin, O'rings on block, Con Rod (m): RE19733 (SUB FOR AT18005), From ESN 179,602

2630 Small pin

2640 Small pin

3010 Block (m) R26160, R32020, R40850

3020 Block (m) R26160, R32020, R40850

6430 Piston (m) RE515037 Tier 2 & Tier 3

6534 Piston (m) RE515037 Tier 2 & Tier 3

7130 Piston (m) RE515037 Tier 2 & Tier 3

2020 Large pin, O'rings on block, Con Rod (m): RE19733 (SUB FOR AT18005), From ESN 158,258

2120 Large pin, O'rings on block, Con Rod (m): RE19733 (SUB FOR AT18005), From ESN 158,258

2510 Large pin, O'rings on block, Con Rod (m): RE19733 (SUB FOR AT18005), From ESN 158,258

3120 Small pin, O'rings on block, Con Rod (m): T20007, R81410, Piston (m): RE53265, T30015, AR78310

4030 Small pin, O'rings on block, Con Rod (m): T20007, R81410, Piston (m): RE53265, T30015, AR78310

4420 Small pin, O'rings on block, Con Rod (m): T20007, R81410, Piston (m): RE53265, T30015, AR78310

4050 Con Rod (m) R66922, R58852, R41423

4240 Con Rod (m) R66922, R58852, R41423

8630 Mid, Con Rod (m): R63959

8640 Mid, Con Rod (m): R63959

8650 Mid, Con Rod (m): R63959

6100 Liter designated

SE6100 Liter designated

4000 Block (m) R40610, R40620, R45950, R47170, R48440

4010 Block (m) R40610, R40620, R45950, R47170, R48440

4020 Block (m) R40610, R40620, R45950, R47170, R48440

2520 Small pin, O'rings on liner, Con Rod (m): T20007, R81410, To ESN 275,483

3140C Liter designated, Con Rod (m): R80032, Piston (m): RE22678

6600 Liter designated, Con Rod (m): R80032, Piston (m): RE22678

7200 Liter designated, Con Rod (m): R80032, Piston (m): RE22678

6430 Piston (m) RE521616 Tier 2 & Tier 3

6534 Piston (m) RE521616 Tier 2 & Tier 3

7130 Piston (m) RE521616 Tier 2 & Tier 3

3010 Early power booster

3020 Early power booster

4955 Low Ring Piston, Con Rod (m): R71074 (P/N AR93341)

4960 Low Ring Piston, Con Rod (m): R71074 (P/N AR93341)

8560 Low Ring Piston, Con Rod (m): R71074 (P/N AR93341)

8570 Low Ring Piston, Con Rod (m): R71074 (P/N AR93341)

820 O'rings on block, Con Rod (m): T20007, R81410, From ESN 154,766

830 O'rings on block, Con Rod (m): T20007, R81410, From ESN 154,766

1020 O'rings on block, Con Rod (m): T20007, R81410, From ESN 154,766

1030 O'rings on block, Con Rod (m): T20007, R81410, From ESN 154,766

6506 Liter designated, Large pin

3020 Block (m) R40700, R47520, R48430, R50610, R72127

5200 Liter designated, Con Rod (m): R51727, R80034

5300 Liter designated, Con Rod (m): R51727, R80034

5400 Liter designated, Con Rod (m): R51727, R80034

4040 Block (m) R49470, R49650, R59850, R72128, R87558

4230 Block (m) R49470, R49650, R59850, R72128, R87558

1520 Small pin, O'rings on liner, Con Rod (m): T20007, R81410, To ESN 179,601

2030 Small pin, O'rings on block, Con Rod (m): T20007, R81410, To ESN 275,483

2120 Small pin, O'rings on block, Con Rod (m): T20007, R81410, To ESN 275,483

4250 Con.Rod (m) R71074 (P/N AR93341)

4440 Con.Rod (m) R71074 (P/N AR93341)

4450 Con.Rod (m) R71074 (P/N AR93341)

4640 Con.Rod (m) R71074 (P/N AR93341)

4650 Con.Rod (m) R71074 (P/N AR93341)

5460 Con.Rod (m) R71074 (P/N AR93341)

6622 Con.Rod (m) R71074 (P/N AR93341)

8630 Late, Con Rod (m): R63959

8640 Late, Con Rod (m): R63959

8650 Late, Con Rod (m): R63959

2955 Liter designated, Con Rod (m): R80034, Piston (m): RE30250

3155 Liter designated, Con Rod (m): R80034, Piston (m): RE30250

3155TSS Liter designated, Con Rod (m): R80034, Piston (m): RE30250

3255 Liter designated, Con Rod (m): R80034, Piston (m): RE30250

3640 Liter designated, Con Rod (m): R80034, Piston (m): RE30250

3650 Liter designated, Con Rod (m): R80034, Piston (m): RE30250

7130 Piston (m) RE515037 Tier 2 & Tier 3

6430 Piston (m) RE515037 Tier 2 & Tier 3

6534 Piston (m) RE515037 Tier 2 & Tier 3

4010 Block (m) R26070, R33180, R34340, R40890, R40900

4020 Block (m) R26070, R33180, R34340, R40890, R40900

8870 To ESN 499,999

2355NCS Con Rod (m): R80032

2355NTSS Con Rod (m): R80032

5103 Piston (m) RE520573

5203 Piston (m) RE520573

7510 Piston (m) RE55512, RE505102

7610 Piston (m) RE55512, RE505102

6605 Piston (m) RE55512, RE505102

6615 Piston (m) RE55512, RE505102

6715 Piston (m) RE55512, RE505102

7210 Piston (m) RE55512, RE505102

7405 Piston (m) RE55512, RE505102

7410 Piston (m) RE55512, RE505102

2840 Large pin, O'rings on block, Con Rod (m): RE16495, Piston (m): AR77762

3130 Large pin, O'rings on block, Con Rod (m): RE16495, Piston (m): AR77762

3530 Large pin, O'rings on block, Con Rod (m): RE16495, Piston (m): AR77762

4030 Large pin, O'rings on block, Con Rod (m): RE16495, Piston (m): AR77762

4425 Large pin, O'rings on block, Con Rod (m): RE16495, Piston (m): AR77762

5020 Con Rod (m) R35048, R58881, R40238, R66927, R53286

6030 Con Rod (m) R35048, R58881, R40238, R66927, R53286

7430E Piston (m) RE515037 Tier 2 & Tier 3

7530E Piston (m) RE515037 Tier 2 & Tier 3

7530 Piston (m) RE515037 Tier 2 & Tier 3

7630 Piston (m) RE515037 Tier 2 & Tier 3

7730 Piston (m) RE515037 Tier 2 & Tier 3

7830 Piston (m) RE515037 Tier 2 & Tier 3

7930 Piston (m) RE515037 Tier 2 & Tier 3

7195J Piston (m) RE515037 Tier 2 & Tier 3

7210J Piston (m) RE515037 Tier 2 & Tier 3

7225J Piston (m) RE515037 Tier 2 & Tier 3

5500 Liter designated, Con Rod (m): R80032, R58979, R113612

6400 Liter designated

6400L Liter designated

6500 Liter designated

6500L Liter designated

SE6400 Liter designated

3550 Con Rod (m): R80032, R113612, Piston (m): RE22678, RE19278

4050 Con Rod (m): R80032, R113612, Piston (m): RE22678, RE19278

7200 Con Rod (m): R80032, R113612, Piston (m): RE22678, RE19278

3140C Con Rod (m): R80032, R113612, Piston (m): RE22678, RE19278

3540 Con Rod (m): R80032, R113612, Piston (m): RE22678, RE19278

4520 To ESN 335,845, Block (m): R43310, R45980, R47020, R47110

4620 To ESN 335,845, Block (m): R43310, R45980, R47020, R47110

5440 To ESN 335,845, Block (m): R43310, R45980, R47020, R47110

4560 High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

4755 High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

4760 High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

7700 High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

7800 High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

8100 High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

8200 High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

4055 High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

8300 High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

4255 High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

4455 High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

4555 High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

5400 Piston (m) RE61270

5400N Piston (m) RE61270

7210J Piston (m) RE515037 Tier 2 & Tier 3

7225J Piston (m) RE515037 Tier 2 & Tier 3

7430E Piston (m) RE515037 Tier 2 & Tier 3

7530E Piston (m) RE515037 Tier 2 & Tier 3

7530 Piston (m) RE515037 Tier 2 & Tier 3

7630 Piston (m) RE515037 Tier 2 & Tier 3

7730 Piston (m) RE515037 Tier 2 & Tier 3

7830 Piston (m) RE515037 Tier 2 & Tier 3

7930 Piston (m) RE515037 Tier 2 & Tier 3

7195J Piston (m) RE515037 Tier 2 & Tier 3

8120 Low Compression Piston. From ESN 200,000. Tier 2.

8220 Low Compression Piston. From ESN 200,000. Tier 2.

8320 Low Compression Piston. From ESN 200,000. Tier 2.

8420 Low Compression Piston. From ESN 200,000. Tier 2.

8520 Low Compression Piston. From ESN 200,000. Tier 2.

8120T Low Compression Piston. From ESN 200,000. Tier 2.

8220T Low Compression Piston. From ESN 200,000. Tier 2.

8320T Low Compression Piston. From ESN 200,000. Tier 2.

8420T Low Compression Piston. From ESN 200,000. Tier 2.

8520T Low Compression Piston. From ESN 200,000. Tier 2.

1420 Small pin, O'rings on block, Con Rod (m): T20007, R81410, To ESN 179,601

1520 Small pin, O'rings on block, Con Rod (m): T20007, R81410, To ESN 179,601

1530 Small pin, O'rings on block, Con Rod (m): T20007, R81410, To ESN 179,601

2030 Large pin, O'rings on block, Con Rod (m): R51727, R80034, From ESN 275,484

2035 Large pin, O'rings on block, Con Rod (m): R51727, R80034, From ESN 275,484

2120 Large pin, O'rings on block, Con Rod (m): R51727, R80034, From ESN 275,484

2440 Large pin, O'rings on block, Con Rod (m): R51727, R80034, From ESN 275,484

2530 Large pin, O'rings on block, Con Rod (m): R51727, R80034, From ESN 275,484

1035 Large pin, O'rings on block, Con Rod (m): R51727, R80034, From ESN 275,484

1130 Large pin, O'rings on block, Con Rod (m): R51727, R80034, From ESN 275,484

1635 Large pin, O'rings on block, Con Rod (m): R51727, R80034, From ESN 275,484

2855 Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

2140 Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

2855N Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

2450 Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

2555 Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

2555TSS Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

2650 Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

2750 Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

2755 Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

2755CS Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

2755TSS Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

2850 Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

7600 Liter designated

6800 Liter designated

6900 Liter designated

7400 Liter designated

7410 Liter designated

8450 Con Rod (m) R57303, R67320

4440 Con Rod (m) R57303, R67320

4640 Con Rod (m) R57303, R67320

4840 Con Rod (m) R57303, R67320

6622 Con Rod (m) R57303, R67320

8430 Con Rod (m) R57303, R67320

8440 Con Rod (m) R57303, R67320

7520 Con Rod (m) R48315, R53287, R58883, R66926

6030 Con Rod (m) R48315, R53287, R58883, R66926

5615 Piston (m) RE59279, RE505101

5715 Piston (m) RE59279, RE505101

6010 Piston (m) RE59279, RE505101

6110 Piston (m) RE59279, RE505101

6610 Piston (m) RE59279, RE505101

5410 Piston (m) RE59279, RE505101

5415 Piston (m) RE59279, RE505101

5420 Piston (m) RE59279, RE505101

5420N Piston (m) RE59279, RE505101

5510 Piston (m) RE59279, RE505101

6410L Piston (m) RE55512, RE505102

6010 Piston (m) RE55512, RE505102

6410S Piston (m) RE55512, RE505102

6110 Piston (m) RE55512, RE505102

6510L Piston (m) RE55512, RE505102

6110L Piston (m) RE55512, RE505102

6610S Piston (m) RE55512, RE505102

6210 Piston (m) RE55512, RE505102

6605 Piston (m) RE55512, RE505102

6210L Piston (m) RE55512, RE505102

6610 Piston (m) RE55512, RE505102

6310 Piston (m) RE55512, RE505102

6310L Piston (m) RE55512, RE505102

6310S Piston (m) RE55512, RE505102

6405 Piston (m) RE55512, RE505102

6410 Piston (m) RE55512, RE505102

6430 Piston (m) RE507758 Tier 2 & Tier 3

6534 Piston (m) RE507758 Tier 2 & Tier 3

7130 Piston (m) RE507758 Tier 2 & Tier 3

6930 Piston (m) RE527039 Tier 2 & Tier 3

7130 Piston (m) RE527039 Tier 2 & Tier 3

1470 Piston (m) RE527039 Tier 2 & Tier 3

7230 Piston (m) RE527039 Tier 2 & Tier 3

1654 Piston (m) RE527039 Tier 2 & Tier 3

7330 Piston (m) RE527039 Tier 2 & Tier 3

1854 Piston (m) RE527039 Tier 2 & Tier 3

7430 Piston (m) RE527039 Tier 2 & Tier 3

2054 Piston (m) RE527039 Tier 2 & Tier 3

6225 Piston (m) RE527039 Tier 2 & Tier 3

6525 Piston (m) RE527039 Tier 2 & Tier 3

6530 Piston (m) RE527039 Tier 2 & Tier 3

6630 Piston (m) RE527039 Tier 2 & Tier 3

6830 Piston (m) RE527039 Tier 2 & Tier 3

7225J Piston (m) RE507758 Tier 2 & Tier 3

7430E Piston (m) RE507758 Tier 2 & Tier 3

7530E Piston (m) RE507758 Tier 2 & Tier 3

7530 Piston (m) RE507758 Tier 2 & Tier 3

7630 Piston (m) RE507758 Tier 2 & Tier 3

7730 Piston (m) RE507758 Tier 2 & Tier 3

7830 Piston (m) RE507758 Tier 2 & Tier 3

7930 Piston (m) RE507758 Tier 2 & Tier 3

7195J Piston (m) RE507758 Tier 2 & Tier 3

7210J Piston (m) RE507758 Tier 2 & Tier 3

8420 Low Compression Piston. To ESN 199,999. Tier 1

8520 Low Compression Piston. To ESN 199,999. Tier 1

9100 Low Compression Piston. To ESN 199,999. Tier 1

9120 Low Compression Piston. To ESN 199,999. Tier 1

8410T Low Compression Piston. To ESN 199,999. Tier 1

8420T Low Compression Piston. To ESN 199,999. Tier 1

8520T Low Compression Piston. To ESN 199,999. Tier 1

8400 Low Compression Piston. To ESN 199,999. Tier 1

8410 Low Compression Piston. To ESN 199,999. Tier 1

2150 Con Rod (m): R80034

2155 Con Rod (m): R80034

2240 Con Rod (m): R80034

1140 Con Rod (m): R80034

5000 Con Rod (m): R80034

1140 Con Rod (m): R80034

1350 Con Rod (m): R80034

1550 Con Rod (m): R80034

1630 Con Rod (m): R80034

1750 Con Rod (m): R80034

1850 Con Rod (m): R80034

2040 Con Rod (m): R80034

2355 Con Rod (m): R80034, Piston (m): RE30250

2355CS Con Rod (m): R80034, Piston (m): RE30250

2450 Con Rod (m): R80034, Piston (m): RE30250

2535 Con Rod (m): R80034, Piston (m): RE30250

2550 Con Rod (m): R80034, Piston (m): RE30250

1640 Con Rod (m): R80034, Piston (m): RE30250

2555CS Con Rod (m): R80034, Piston (m): RE30250

1840 Con Rod (m): R80034, Piston (m): RE30250

2650 Con Rod (m): R80034, Piston (m): RE30250

2130 Con Rod (m): R80034, Piston (m): RE30250

2730 Con Rod (m): R80034, Piston (m): RE30250

2135 Con Rod (m): R80034, Piston (m): RE30250

2735 Con Rod (m): R80034, Piston (m): RE30250

2250 Con Rod (m): R80034, Piston (m): RE30250

3330 Con Rod (m): R80034, Piston (m): RE30250

2350 Con Rod (m): R80034, Piston (m): RE30250

6310 Liter designated, Con Rod (m): R80032, R122191, R113612, Piston (m): RE19282, RE30250

5500N Liter designated, Con Rod (m): R80032, R122191, R113612, Piston (m): RE19282, RE30250

5700 Liter designated, Con Rod (m): R80032, R122191, R113612, Piston (m): RE19282, RE30250

6200 Liter designated, Con Rod (m): R80032, R122191, R113612, Piston (m): RE19282, RE30250

6200L Liter designated, Con Rod (m): R80032, R122191, R113612, Piston (m): RE19282, RE30250

SE6200 Liter designated, Con Rod (m): R80032, R122191, R113612, Piston (m): RE19282, RE30250

6210 Liter designated, Con Rod (m): R80032, R122191, R113612, Piston (m): RE19282, RE30250

6300 Liter designated, Con Rod (m): R80032, R122191, R113612, Piston (m): RE19282, RE30250

6300L Liter designated, Con Rod (m): R80032, R122191, R113612, Piston (m): RE19282, RE30250

SE6300 Liter designated, Con Rod (m): R80032, R122191, R113612, Piston (m): RE19282, RE30250

2950 Con Rod (m): R80034, Piston (m): RE30250

4420 Con Rod (m): R80034, Piston (m): RE30250

2955 Con Rod (m): R80034, Piston (m): RE30250

4530 Con Rod (m): R80034, Piston (m): RE30250

3040 Con Rod (m): R80034, Piston (m): RE30250

3050 Con Rod (m): R80034, Piston (m): RE30250

3140 Con Rod (m): R80034, Piston (m): RE30250

3150 Con Rod (m): R80034, Piston (m): RE30250

3155 Con Rod (m): R80034, Piston (m): RE30250

3155TSS Con Rod (m): R80034, Piston (m): RE30250

3255 Con Rod (m): R80034, Piston (m): RE30250

3350 Con Rod (m): R80034, Piston (m): RE30250

2940 Con Rod (m): R80034, Piston (m): RE30250

3640 Con Rod (m): R80034, Piston (m): RE30250

4010 Block (m) R40930

4020 Block (m) R40930

8440 Con Rod (m) R71074 (P/N AR93341)

8450 Con Rod (m) R71074 (P/N AR93341)

4840 Con Rod (m) R71074 (P/N AR93341)

4850 Con Rod (m) R71074 (P/N AR93341)

8430 Con Rod (m) R71074 (P/N AR93341)

3100 Piston (m) RE61467

5105 Piston (m) RE61467

5200 Piston (m) RE61467

5205 Piston (m) RE61467

5210 Piston (m) RE61467

5220 Piston (m) RE61467

5300 Piston (m) RE61467

5310 Piston (m) RE61467

5310N Piston (m) RE61467

5625N Piston (m) RE59277, RE505100

5525 Piston (m) RE59277, RE505100

5615 Piston (m) RE59277, RE505100

5625 Piston (m) RE59277, RE505100

5715 Piston (m) RE59277, RE505100

5725 Piston (m) RE59277, RE505100

3410 Piston (m) RE59277, RE505100

3410X Piston (m) RE59277, RE505100

4890 Piston (m) RE59277, RE505100

5425N Piston (m) RE59277, RE505100

5415 Piston (m) RE59277, RE505100

5510N Piston (m) RE59277, RE505100

5425 Piston (m) RE59277, RE505100

5520N Piston (m) RE59277, RE505100

5510 Piston (m) RE59277, RE505100

5525N Piston (m) RE59277, RE505100

5520 Piston (m) RE59277, RE505100

6100D Piston (m) RE527039 Tier 2 & Tier 3

6430 Piston (m) RE527039 Tier 2 & Tier 3

6110D Piston (m) RE527039 Tier 2 & Tier 3

6534 Piston (m) RE527039 Tier 2 & Tier 3

6115D Piston (m) RE527039 Tier 2 & Tier 3

5080R Piston (m) RE527039 Tier 2 & Tier 3

6125D Piston (m) RE527039 Tier 2 & Tier 3

5080RN Piston (m) RE527039 Tier 2 & Tier 3

6130D Piston (m) RE527039 Tier 2 & Tier 3

5090R Piston (m) RE527039 Tier 2 & Tier 3

6140D Piston (m) RE527039 Tier 2 & Tier 3

5090RN Piston (m) RE527039 Tier 2 & Tier 3

6130 Piston (m) RE527039 Tier 2 & Tier 3

5100R Piston (m) RE527039 Tier 2 & Tier 3

6230 Piston (m) RE527039 Tier 2 & Tier 3

5100RN Piston (m) RE527039 Tier 2 & Tier 3

6325 Piston (m) RE527039 Tier 2 & Tier 3

5105M Piston (m) RE527039 Tier 2 & Tier 3

6330 Piston (m) RE527039 Tier 2 & Tier 3

5105ML Piston (m) RE527039 Tier 2 & Tier 3

6425 Piston (m) RE527039 Tier 2 & Tier 3

6515 Piston (m) RE59279, RE505101

6520 Piston (m) RE59279, RE505101

SE6520 Piston (m) RE59279, RE505101

6205 Piston (m) RE59279, RE505101

6505 Piston (m) RE59279, RE505101

6510 Piston (m) RE59279, RE505101

SE6510 Piston (m) RE59279, RE505101

7210J Piston (m) RE521616 Tier 2 & Tier 3

7225J Piston (m) RE521616 Tier 2 & Tier 3

7430E Piston (m) RE521616 Tier 2 & Tier 3

7530E Piston (m) RE521616 Tier 2 & Tier 3

7530 Piston (m) RE521616 Tier 2 & Tier 3

7630 Piston (m) RE521616 Tier 2 & Tier 3

7730 Piston (m) RE521616 Tier 2 & Tier 3

7830 Piston (m) RE521616 Tier 2 & Tier 3

7930 Piston (m) RE521616 Tier 2 & Tier 3

7195J Piston (m) RE521616 Tier 2 & Tier 3

8400 High Compression Piston. To ESN 199,999. Tier 1

9100 High Compression Piston. To ESN 199,999. Tier 1

8100T High Compression Piston. To ESN 199,999. Tier 1

7710 High Compression Piston. To ESN 199,999. Tier 1

8110T High Compression Piston. To ESN 199,999. Tier 1

7810 High Compression Piston. To ESN 199,999. Tier 1

8200T High Compression Piston. To ESN 199,999. Tier 1

8100 High Compression Piston. To ESN 199,999. Tier 1

8210T High Compression Piston. To ESN 199,999. Tier 1

8110 High Compression Piston. To ESN 199,999. Tier 1

8300T High Compression Piston. To ESN 199,999. Tier 1

8200 High Compression Piston. To ESN 199,999. Tier 1

8310T High Compression Piston. To ESN 199,999. Tier 1

8210 High Compression Piston. To ESN 199,999. Tier 1

8400T High Compression Piston. To ESN 199,999. Tier 1

8300 High Compression Piston. To ESN 199,999. Tier 1

8310 High Compression Piston. To ESN 199,999. Tier 1

8520 High Compression Piston. From ESN 200,000. Tier 2.

7710 High Compression Piston. From ESN 200,000. Tier 2.

7810 High Compression Piston. From ESN 200,000. Tier 2.

8120T High Compression Piston. From ESN 200,000. Tier 2.

8220T High Compression Piston. From ESN 200,000. Tier 2.

8320T High Compression Piston. From ESN 200,000. Tier 2.

8420T High Compression Piston. From ESN 200,000. Tier 2.

8120 High Compression Piston. From ESN 200,000. Tier 2.

8520T High Compression Piston. From ESN 200,000. Tier 2.

8220 High Compression Piston. From ESN 200,000. Tier 2.

7820 High Compression Piston. From ESN 200,000. Tier 2.

8320 High Compression Piston. From ESN 200,000. Tier 2.

7920 High Compression Piston. From ESN 200,000. Tier 2.

8420 High Compression Piston. From ESN 200,000. Tier 2.

8330 ILS 9.0 Liter Tier 2 & Tier 3

8430 HDMFWD 9.0 Liter Tier 2 & Tier 3

3520 9.0 Liter Tier 2 & Tier 3

8285R 9.0 Liter Tier 2 & Tier 3

8370R 9.0 Liter Tier 2 & Tier 3

8130 MFWD 9.0 Liter Tier 2 & Tier 3

8330 HDMFWD 9.0 Liter Tier 2 & Tier 3

8235R 9.0 Liter Tier 2 & Tier 3

8430 MFWD 9.0 Liter Tier 2 & Tier 3

8520 9.0 Liter Tier 2 & Tier 3

8295R HDMFWD 9.0 Liter Tier 2 & Tier 3

8370RT 9.0 Liter Tier 2 & Tier 3

8225R 9.0 Liter Tier 2 & Tier 3

8330 ILS 9.0 Liter Tier 2 & Tier 3

8245R 9.0 Liter Tier 2 & Tier 3

8430 9.0 Liter Tier 2 & Tier 3

8130 9.0 Liter Tier 2 & Tier 3

8295R ILS 9.0 Liter Tier 2 & Tier 3

8320T 9.0 Liter Tier 2 & Tier 3

8225R ILS 9.0 Liter Tier 2 & Tier 3

8330 MFWD 9.0 Liter Tier 2 & Tier 3

8245R HDMFWD 9.0 Liter Tier 2 & Tier 3

8530 9.0 Liter Tier 2 & Tier 3

8230 9.0 Liter Tier 2 & Tier 3

8295R MFWD 9.0 Liter Tier 2 & Tier 3

8320RT 9.0 Liter Tier 2 & Tier 3

8225R MFWD 9.0 Liter Tier 2 & Tier 3

8330T 9.0 Liter Tier 2 & Tier 3

8245R ILS 9.0 Liter Tier 2 & Tier 3

8430T 9.0 Liter Tier 2 & Tier 3

8330 9.0 Liter Tier 2 & Tier 3

8295RT 9.0 Liter Tier 2 & Tier 3

8230 HDMFWD 9.0 Liter Tier 2 & Tier 3

8335R 9.0 Liter Tier 2 & Tier 3

8245R MFWD 9.0 Liter Tier 2 & Tier 3

8530 HDMFWD 9.0 Liter Tier 2 & Tier 3

8430 9.0 Liter Tier 2 & Tier 3

8310R 9.0 Liter Tier 2 & Tier 3

8230 ILS 9.0 Liter Tier 2 & Tier 3

8335RT 9.0 Liter Tier 2 & Tier 3

8260R 9.0 Liter Tier 2 & Tier 3

8530 ILS 9.0 Liter Tier 2 & Tier 3

8530 9.0 Liter Tier 2 & Tier 3

8310RT 9.0 Liter Tier 2 & Tier 3

8230 MFWD 9.0 Liter Tier 2 & Tier 3

8345R 9.0 Liter Tier 2 & Tier 3

8270R 9.0 Liter Tier 2 & Tier 3

870G 9.0 Liter Tier 2 & Tier 3

9230 9.0 Liter Tier 2 & Tier 3

8320R 9.0 Liter Tier 2 & Tier 3

8230 9.0 Liter Tier 2 & Tier 3

8345R ILS 9.0 Liter Tier 2 & Tier 3

8270R HDMFWD 9.0 Liter Tier 2 & Tier 3

870GP 9.0 Liter Tier 2 & Tier 3

8130 AT2 ILS 9.0 Liter Tier 2 & Tier 3

8320R MFWD 9.0 Liter Tier 2 & Tier 3

8230T 9.0 Liter Tier 2 & Tier 3

8345R MFWD 9.0 Liter Tier 2 & Tier 3

8270R ILS 9.0 Liter Tier 2 & Tier 3

8360R 9.0 Liter Tier 2 & Tier 3

8130 AT2 MFWD 9.0 Liter Tier 2 & Tier 3

8320RT 9.0 Liter Tier 2 & Tier 3

8330 9.0 Liter Tier 2 & Tier 3

8345RT 9.0 Liter Tier 2 & Tier 3

2854 9.0 Liter Tier 2 & Tier 3

8270R MFWD 9.0 Liter Tier 2 & Tier 3

8360RT 9.0 Liter Tier 2 & Tier 3

8130 ILS 9.0 Liter Tier 2 & Tier 3

8330 HD MFWD 9.0 Liter Tier 2 & Tier 3

JD1220 88mm Bore Non Turbo

JD1200 88mm Bore Non Turbo

JD1400 88mm Bore Non Turbo

5600 Liter designated, Con Rod (m): R80034, Piston (m): RE30250, RE18697

3420 O'rings on block, Con Rod (m): T20007, R81410, Piston (m): T23481

6603 Piston (m) RE59277, RE505100

2020 O'rings on liner, Con Rod (m): RE19733 (SUB FOR AT18005), To ESN 158,257

2510 O'rings on liner, Con Rod (m): RE19733 (SUB FOR AT18005), To ESN 158,257

3120 Small pin, O'rings on liner, Con Rod (m): T20007, R81410, Piston (m): RE53265, T30015, R51451, AR78310

3020 Block (m) R46350, R46430, R40910

8630 Early, Con Rod (m): R66925, R57484

4010 Block (m) R26070, R33180, R34340, R40890, R40900

4020 Block (m) R26070, R33180, R34340, R40890, R40900

820 O'rings on liner, Con Rod (m): T20007 R81410

1020 O'rings on liner, Con Rod (m): T20007 R81410

1030 O'rings on liner, Con Rod (m): T20007 R81410

4430 From ESN 335,846, Block (m): R49470, R49650, R59850, R72128, R87558

4630 From ESN 335,846, Block (m): R49470, R49650, R59850, R72128, R87558

5440 From ESN 335,846, Block (m): R49470, R49650, R59850, R72128, R87558

5400 Piston (m) RE500211

5400N Piston (m) RE500211

1530 Large pin, O'rings on block, Con Rod (m): RE19733 (SUB FOR AT18005), From ESN 179,602

2040 Large pin, O'rings on block, Con Rod (m): RE19733 (SUB FOR AT18005), From ESN 179,602

2330 Large pin, O'rings on block, Con Rod (m): RE19733 (SUB FOR AT18005), From ESN 179,602

2630 Small pin

2640 Small pin

3010 Block (m) R26160, R32020, R40850

3020 Block (m) R26160, R32020, R40850

6430 Piston (m) RE515037 Tier 2 & Tier 3

6534 Piston (m) RE515037 Tier 2 & Tier 3

7130 Piston (m) RE515037 Tier 2 & Tier 3

2020 Large pin, O'rings on block, Con Rod (m): RE19733 (SUB FOR AT18005), From ESN 158,258

2120 Large pin, O'rings on block, Con Rod (m): RE19733 (SUB FOR AT18005), From ESN 158,258

2510 Large pin, O'rings on block, Con Rod (m): RE19733 (SUB FOR AT18005), From ESN 158,258

3120 Small pin, O'rings on block, Con Rod (m): T20007, R81410, Piston (m): RE53265, T30015, AR78310

4030 Small pin, O'rings on block, Con Rod (m): T20007, R81410, Piston (m): RE53265, T30015, AR78310

4420 Small pin, O'rings on block, Con Rod (m): T20007, R81410, Piston (m): RE53265, T30015, AR78310

4050 Con Rod (m) R66922, R58852, R41423

4240 Con Rod (m) R66922, R58852, R41423

8630 Mid, Con Rod (m): R63959

8640 Mid, Con Rod (m): R63959

8650 Mid, Con Rod (m): R63959

6100 Liter designated

SE6100 Liter designated

4000 Block (m) R40610, R40620, R45950, R47170, R48440

4010 Block (m) R40610, R40620, R45950, R47170, R48440

4020 Block (m) R40610, R40620, R45950, R47170, R48440

2520 Small pin, O'rings on liner, Con Rod (m): T20007, R81410, To ESN 275,483

3140C Liter designated, Con Rod (m): R80032, Piston (m): RE22678

6600 Liter designated, Con Rod (m): R80032, Piston (m): RE22678

7200 Liter designated, Con Rod (m): R80032, Piston (m): RE22678

6430 Piston (m) RE521616 Tier 2 & Tier 3

6534 Piston (m) RE521616 Tier 2 & Tier 3

7130 Piston (m) RE521616 Tier 2 & Tier 3

3010 Early power booster

3020 Early power booster

4955 Low Ring Piston, Con Rod (m): R71074 (P/N AR93341)

4960 Low Ring Piston, Con Rod (m): R71074 (P/N AR93341)

8560 Low Ring Piston, Con Rod (m): R71074 (P/N AR93341)

8570 Low Ring Piston, Con Rod (m): R71074 (P/N AR93341)

820 O'rings on block, Con Rod (m): T20007, R81410, From ESN 154,766

830 O'rings on block, Con Rod (m): T20007, R81410, From ESN 154,766

1020 O'rings on block, Con Rod (m): T20007, R81410, From ESN 154,766

1030 O'rings on block, Con Rod (m): T20007, R81410, From ESN 154,766

6506 Liter designated, Large pin

3020 Block (m) R40700, R47520, R48430, R50610, R72127

5200 Liter designated, Con Rod (m): R51727, R80034

5300 Liter designated, Con Rod (m): R51727, R80034

5400 Liter designated, Con Rod (m): R51727, R80034

4040 Block (m) R49470, R49650, R59850, R72128, R87558

4230 Block (m) R49470, R49650, R59850, R72128, R87558

1520 Small pin, O'rings on liner, Con Rod (m): T20007, R81410, To ESN 179,601

2030 Small pin, O'rings on block, Con Rod (m): T20007, R81410, To ESN 275,483

2120 Small pin, O'rings on block, Con Rod (m): T20007, R81410, To ESN 275,483

4250 Con.Rod (m) R71074 (P/N AR93341)

4440 Con.Rod (m) R71074 (P/N AR93341)

4450 Con.Rod (m) R71074 (P/N AR93341)

4640 Con.Rod (m) R71074 (P/N AR93341)

4650 Con.Rod (m) R71074 (P/N AR93341)

5460 Con.Rod (m) R71074 (P/N AR93341)

6622 Con.Rod (m) R71074 (P/N AR93341)

8630 Late, Con Rod (m): R63959

8640 Late, Con Rod (m): R63959

8650 Late, Con Rod (m): R63959

2955 Liter designated, Con Rod (m): R80034, Piston (m): RE30250

3155 Liter designated, Con Rod (m): R80034, Piston (m): RE30250

3155TSS Liter designated, Con Rod (m): R80034, Piston (m): RE30250

3255 Liter designated, Con Rod (m): R80034, Piston (m): RE30250

3640 Liter designated, Con Rod (m): R80034, Piston (m): RE30250

3650 Liter designated, Con Rod (m): R80034, Piston (m): RE30250

7130 Piston (m) RE515037 Tier 2 & Tier 3

6430 Piston (m) RE515037 Tier 2 & Tier 3

6534 Piston (m) RE515037 Tier 2 & Tier 3

4010 Block (m) R26070, R33180, R34340, R40890, R40900

4020 Block (m) R26070, R33180, R34340, R40890, R40900

8870 To ESN 499,999

2355NCS Con Rod (m): R80032

2355NTSS Con Rod (m): R80032

5103 Piston (m) RE520573

5203 Piston (m) RE520573

7510 Piston (m) RE55512, RE505102

7610 Piston (m) RE55512, RE505102

6605 Piston (m) RE55512, RE505102

6615 Piston (m) RE55512, RE505102

6715 Piston (m) RE55512, RE505102

7210 Piston (m) RE55512, RE505102

7405 Piston (m) RE55512, RE505102

7410 Piston (m) RE55512, RE505102

2840 Large pin, O'rings on block, Con Rod (m): RE16495, Piston (m): AR77762

3130 Large pin, O'rings on block, Con Rod (m): RE16495, Piston (m): AR77762

3530 Large pin, O'rings on block, Con Rod (m): RE16495, Piston (m): AR77762

4030 Large pin, O'rings on block, Con Rod (m): RE16495, Piston (m): AR77762

4425 Large pin, O'rings on block, Con Rod (m): RE16495, Piston (m): AR77762

5020 Con Rod (m) R35048, R58881, R40238, R66927, R53286

6030 Con Rod (m) R35048, R58881, R40238, R66927, R53286

7430E Piston (m) RE515037 Tier 2 & Tier 3

7530E Piston (m) RE515037 Tier 2 & Tier 3

7530 Piston (m) RE515037 Tier 2 & Tier 3

7630 Piston (m) RE515037 Tier 2 & Tier 3

7730 Piston (m) RE515037 Tier 2 & Tier 3

7830 Piston (m) RE515037 Tier 2 & Tier 3

7930 Piston (m) RE515037 Tier 2 & Tier 3

7195J Piston (m) RE515037 Tier 2 & Tier 3

7210J Piston (m) RE515037 Tier 2 & Tier 3

7225J Piston (m) RE515037 Tier 2 & Tier 3

5500 Liter designated, Con Rod (m): R80032, R58979, R113612

6400 Liter designated

6400L Liter designated

6500 Liter designated

6500L Liter designated

SE6400 Liter designated

3550 Con Rod (m): R80032, R113612, Piston (m): RE22678, RE19278

4050 Con Rod (m): R80032, R113612, Piston (m): RE22678, RE19278

7200 Con Rod (m): R80032, R113612, Piston (m): RE22678, RE19278

3140C Con Rod (m): R80032, R113612, Piston (m): RE22678, RE19278

3540 Con Rod (m): R80032, R113612, Piston (m): RE22678, RE19278

4520 To ESN 335,845, Block (m): R43310, R45980, R47020, R47110

4620 To ESN 335,845, Block (m): R43310, R45980, R47020, R47110

5440 To ESN 335,845, Block (m): R43310, R45980, R47020, R47110

4560 High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

4755 High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

4760 High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

7700 High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

7800 High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

8100 High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

8200 High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

4055 High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

8300 High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

4255 High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

4455 High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

4555 High Ring Piston, Con Rod (m): R71074 (P/N AR93341)

5400 Piston (m) RE61270

5400N Piston (m) RE61270

7210J Piston (m) RE515037 Tier 2 & Tier 3

7225J Piston (m) RE515037 Tier 2 & Tier 3

7430E Piston (m) RE515037 Tier 2 & Tier 3

7530E Piston (m) RE515037 Tier 2 & Tier 3

7530 Piston (m) RE515037 Tier 2 & Tier 3

7630 Piston (m) RE515037 Tier 2 & Tier 3

7730 Piston (m) RE515037 Tier 2 & Tier 3

7830 Piston (m) RE515037 Tier 2 & Tier 3

7930 Piston (m) RE515037 Tier 2 & Tier 3

7195J Piston (m) RE515037 Tier 2 & Tier 3

8120 Low Compression Piston. From ESN 200,000. Tier 2.

8220 Low Compression Piston. From ESN 200,000. Tier 2.

8320 Low Compression Piston. From ESN 200,000. Tier 2.

8420 Low Compression Piston. From ESN 200,000. Tier 2.

8520 Low Compression Piston. From ESN 200,000. Tier 2.

8120T Low Compression Piston. From ESN 200,000. Tier 2.

8220T Low Compression Piston. From ESN 200,000. Tier 2.

8320T Low Compression Piston. From ESN 200,000. Tier 2.

8420T Low Compression Piston. From ESN 200,000. Tier 2.

8520T Low Compression Piston. From ESN 200,000. Tier 2.

1420 Small pin, O'rings on block, Con Rod (m): T20007, R81410, To ESN 179,601

1520 Small pin, O'rings on block, Con Rod (m): T20007, R81410, To ESN 179,601

1530 Small pin, O'rings on block, Con Rod (m): T20007, R81410, To ESN 179,601

2030 Large pin, O'rings on block, Con Rod (m): R51727, R80034, From ESN 275,484

2035 Large pin, O'rings on block, Con Rod (m): R51727, R80034, From ESN 275,484

2120 Large pin, O'rings on block, Con Rod (m): R51727, R80034, From ESN 275,484

2440 Large pin, O'rings on block, Con Rod (m): R51727, R80034, From ESN 275,484

2530 Large pin, O'rings on block, Con Rod (m): R51727, R80034, From ESN 275,484

1035 Large pin, O'rings on block, Con Rod (m): R51727, R80034, From ESN 275,484

1130 Large pin, O'rings on block, Con Rod (m): R51727, R80034, From ESN 275,484

1635 Large pin, O'rings on block, Con Rod (m): R51727, R80034, From ESN 275,484

2855 Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

2140 Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

2855N Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

2450 Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

2555 Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

2555TSS Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

2650 Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

2750 Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

2755 Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

2755CS Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

2755TSS Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

2850 Con Rod (m) R80032, R113612, R122191, Piston (m): RE33115

7600 Liter designated

6800 Liter designated

6900 Liter designated

7400 Liter designated

7410 Liter designated

8450 Con Rod (m) R57303, R67320

4440 Con Rod (m) R57303, R67320

4640 Con Rod (m) R57303, R67320

4840 Con Rod (m) R57303, R67320

6622 Con Rod (m) R57303, R67320

8430 Con Rod (m) R57303, R67320

8440 Con Rod (m) R57303, R67320

7520 Con Rod (m) R48315, R53287, R58883, R66926

6030 Con Rod (m) R48315, R53287, R58883, R66926

5615 Piston (m) RE59279, RE505101

5715 Piston (m) RE59279, RE505101

6010 Piston (m) RE59279, RE505101

6110 Piston (m) RE59279, RE505101

6610 Piston (m) RE59279, RE505101

5410 Piston (m) RE59279, RE505101

5415 Piston (m) RE59279, RE505101

5420 Piston (m) RE59279, RE505101

5420N Piston (m) RE59279, RE505101

5510 Piston (m) RE59279, RE505101

6410L Piston (m) RE55512, RE505102

6010 Piston (m) RE55512, RE505102

6410S Piston (m) RE55512, RE505102

6110 Piston (m) RE55512, RE505102

6510L Piston (m) RE55512, RE505102

6110L Piston (m) RE55512, RE505102

6610S Piston (m) RE55512, RE505102

6210 Piston (m) RE55512, RE505102

6605 Piston (m) RE55512, RE505102

6210L Piston (m) RE55512, RE505102

6610 Piston (m) RE55512, RE505102

6310 Piston (m) RE55512, RE505102

6310L Piston (m) RE55512, RE505102

6310S Piston (m) RE55512, RE505102

6405 Piston (m) RE55512, RE505102

6410 Piston (m) RE55512, RE505102

6430 Piston (m) RE507758 Tier 2 & Tier 3

6534 Piston (m) RE507758 Tier 2 & Tier 3

7130 Piston (m) RE507758 Tier 2 & Tier 3

6930 Piston (m) RE527039 Tier 2 & Tier 3

7130 Piston (m) RE527039 Tier 2 & Tier 3

1470 Piston (m) RE527039 Tier 2 & Tier 3

7230 Piston (m) RE527039 Tier 2 & Tier 3

1654 Piston (m) RE527039 Tier 2 & Tier 3

7330 Piston (m) RE527039 Tier 2 & Tier 3

1854 Piston (m) RE527039 Tier 2 & Tier 3

7430 Piston (m) RE527039 Tier 2 & Tier 3

2054 Piston (m) RE527039 Tier 2 & Tier 3

6225 Piston (m) RE527039 Tier 2 & Tier 3

6525 Piston (m) RE527039 Tier 2 & Tier 3

6530 Piston (m) RE527039 Tier 2 & Tier 3

6630 Piston (m) RE527039 Tier 2 & Tier 3

6830 Piston (m) RE527039 Tier 2 & Tier 3

7225J Piston (m) RE507758 Tier 2 & Tier 3

7430E Piston (m) RE507758 Tier 2 & Tier 3

7530E Piston (m) RE507758 Tier 2 & Tier 3

7530 Piston (m) RE507758 Tier 2 & Tier 3

7630 Piston (m) RE507758 Tier 2 & Tier 3

7730 Piston (m) RE507758 Tier 2 & Tier 3

7830 Piston (m) RE507758 Tier 2 & Tier 3

7930 Piston (m) RE507758 Tier 2 & Tier 3

7195J Piston (m) RE507758 Tier 2 & Tier 3

7210J Piston (m) RE507758 Tier 2 & Tier 3

8420 Low Compression Piston. To ESN 199,999. Tier 1

8520 Low Compression Piston. To ESN 199,999. Tier 1

9100 Low Compression Piston. To ESN 199,999. Tier 1

9120 Low Compression Piston. To ESN 199,999. Tier 1

8410T Low Compression Piston. To ESN 199,999. Tier 1

8420T Low Compression Piston. To ESN 199,999. Tier 1

8520T Low Compression Piston. To ESN 199,999. Tier 1

8400 Low Compression Piston. To ESN 199,999. Tier 1

8410 Low Compression Piston. To ESN 199,999. Tier 1

2150 Con Rod (m): R80034

2155 Con Rod (m): R80034

2240 Con Rod (m): R80034

1140 Con Rod (m): R80034

5000 Con Rod (m): R80034

1140 Con Rod (m): R80034

1350 Con Rod (m): R80034

1550 Con Rod (m): R80034

1630 Con Rod (m): R80034

1750 Con Rod (m): R80034

1850 Con Rod (m): R80034

2040 Con Rod (m): R80034

2355 Con Rod (m): R80034, Piston (m): RE30250

2355CS Con Rod (m): R80034, Piston (m): RE30250

2450 Con Rod (m): R80034, Piston (m): RE30250

2535 Con Rod (m): R80034, Piston (m): RE30250

2550 Con Rod (m): R80034, Piston (m): RE30250

1640 Con Rod (m): R80034, Piston (m): RE30250

2555CS Con Rod (m): R80034, Piston (m): RE30250

1840 Con Rod (m): R80034, Piston (m): RE30250

2650 Con Rod (m): R80034, Piston (m): RE30250

2130 Con Rod (m): R80034, Piston (m): RE30250

2730 Con Rod (m): R80034, Piston (m): RE30250

2135 Con Rod (m): R80034, Piston (m): RE30250

2735 Con Rod (m): R80034, Piston (m): RE30250

2250 Con Rod (m): R80034, Piston (m): RE30250

3330 Con Rod (m): R80034, Piston (m): RE30250

2350 Con Rod (m): R80034, Piston (m): RE30250

6310 Liter designated, Con Rod (m): R80032, R122191, R113612, Piston (m): RE19282, RE30250

5500N Liter designated, Con Rod (m): R80032, R122191, R113612, Piston (m): RE19282, RE30250

5700 Liter designated, Con Rod (m): R80032, R122191, R113612, Piston (m): RE19282, RE30250

6200 Liter designated, Con Rod (m): R80032, R122191, R113612, Piston (m): RE19282, RE30250

6200L Liter designated, Con Rod (m): R80032, R122191, R113612, Piston (m): RE19282, RE30250

SE6200 Liter designated, Con Rod (m): R80032, R122191, R113612, Piston (m): RE19282, RE30250

6210 Liter designated, Con Rod (m): R80032, R122191, R113612, Piston (m): RE19282, RE30250

6300 Liter designated, Con Rod (m): R80032, R122191, R113612, Piston (m): RE19282, RE30250

6300L Liter designated, Con Rod (m): R80032, R122191, R113612, Piston (m): RE19282, RE30250

SE6300 Liter designated, Con Rod (m): R80032, R122191, R113612, Piston (m): RE19282, RE30250

2950 Con Rod (m): R80034, Piston (m): RE30250

4420 Con Rod (m): R80034, Piston (m): RE30250

2955 Con Rod (m): R80034, Piston (m): RE30250

4530 Con Rod (m): R80034, Piston (m): RE30250

3040 Con Rod (m): R80034, Piston (m): RE30250

3050 Con Rod (m): R80034, Piston (m): RE30250

3140 Con Rod (m): R80034, Piston (m): RE30250

3150 Con Rod (m): R80034, Piston (m): RE30250

3155 Con Rod (m): R80034, Piston (m): RE30250

3155TSS Con Rod (m): R80034, Piston (m): RE30250

3255 Con Rod (m): R80034, Piston (m): RE30250

3350 Con Rod (m): R80034, Piston (m): RE30250

2940 Con Rod (m): R80034, Piston (m): RE30250

3640 Con Rod (m): R80034, Piston (m): RE30250

4010 Block (m) R40930

4020 Block (m) R40930

8440 Con Rod (m) R71074 (P/N AR93341)

8450 Con Rod (m) R71074 (P/N AR93341)

4840 Con Rod (m) R71074 (P/N AR93341)

4850 Con Rod (m) R71074 (P/N AR93341)

8430 Con Rod (m) R71074 (P/N AR93341)

3100 Piston (m) RE61467

5105 Piston (m) RE61467

5200 Piston (m) RE61467

5205 Piston (m) RE61467

5210 Piston (m) RE61467

5220 Piston (m) RE61467

5300 Piston (m) RE61467

5310 Piston (m) RE61467

5310N Piston (m) RE61467

5625N Piston (m) RE59277, RE505100

5525 Piston (m) RE59277, RE505100

5615 Piston (m) RE59277, RE505100

5625 Piston (m) RE59277, RE505100

5715 Piston (m) RE59277, RE505100

5725 Piston (m) RE59277, RE505100

3410 Piston (m) RE59277, RE505100

3410X Piston (m) RE59277, RE505100

4890 Piston (m) RE59277, RE505100

5425N Piston (m) RE59277, RE505100

5415 Piston (m) RE59277, RE505100

5510N Piston (m) RE59277, RE505100

5425 Piston (m) RE59277, RE505100

5520N Piston (m) RE59277, RE505100

5510 Piston (m) RE59277, RE505100

5525N Piston (m) RE59277, RE505100

5520 Piston (m) RE59277, RE505100

6100D Piston (m) RE527039 Tier 2 & Tier 3

6430 Piston (m) RE527039 Tier 2 & Tier 3

6110D Piston (m) RE527039 Tier 2 & Tier 3

6534 Piston (m) RE527039 Tier 2 & Tier 3

6115D Piston (m) RE527039 Tier 2 & Tier 3

5080R Piston (m) RE527039 Tier 2 & Tier 3

6125D Piston (m) RE527039 Tier 2 & Tier 3

5080RN Piston (m) RE527039 Tier 2 & Tier 3

6130D Piston (m) RE527039 Tier 2 & Tier 3

5090R Piston (m) RE527039 Tier 2 & Tier 3

6140D Piston (m) RE527039 Tier 2 & Tier 3

5090RN Piston (m) RE527039 Tier 2 & Tier 3

6130 Piston (m) RE527039 Tier 2 & Tier 3

5100R Piston (m) RE527039 Tier 2 & Tier 3

6230 Piston (m) RE527039 Tier 2 & Tier 3

5100RN Piston (m) RE527039 Tier 2 & Tier 3

6325 Piston (m) RE527039 Tier 2 & Tier 3

5105M Piston (m) RE527039 Tier 2 & Tier 3

6330 Piston (m) RE527039 Tier 2 & Tier 3

5105ML Piston (m) RE527039 Tier 2 & Tier 3

6425 Piston (m) RE527039 Tier 2 & Tier 3

6515 Piston (m) RE59279, RE505101

6520 Piston (m) RE59279, RE505101

SE6520 Piston (m) RE59279, RE505101

6205 Piston (m) RE59279, RE505101

6505 Piston (m) RE59279, RE505101

6510 Piston (m) RE59279, RE505101

SE6510 Piston (m) RE59279, RE505101

7210J Piston (m) RE521616 Tier 2 & Tier 3

7225J Piston (m) RE521616 Tier 2 & Tier 3

7430E Piston (m) RE521616 Tier 2 & Tier 3

7530E Piston (m) RE521616 Tier 2 & Tier 3

7530 Piston (m) RE521616 Tier 2 & Tier 3

7630 Piston (m) RE521616 Tier 2 & Tier 3

7730 Piston (m) RE521616 Tier 2 & Tier 3

7830 Piston (m) RE521616 Tier 2 & Tier 3

7930 Piston (m) RE521616 Tier 2 & Tier 3

7195J Piston (m) RE521616 Tier 2 & Tier 3

8400 High Compression Piston. To ESN 199,999. Tier 1

9100 High Compression Piston. To ESN 199,999. Tier 1

8100T High Compression Piston. To ESN 199,999. Tier 1

7710 High Compression Piston. To ESN 199,999. Tier 1

8110T High Compression Piston. To ESN 199,999. Tier 1

7810 High Compression Piston. To ESN 199,999. Tier 1

8200T High Compression Piston. To ESN 199,999. Tier 1

8100 High Compression Piston. To ESN 199,999. Tier 1

8210T High Compression Piston. To ESN 199,999. Tier 1

8110 High Compression Piston. To ESN 199,999. Tier 1

8300T High Compression Piston. To ESN 199,999. Tier 1

8200 High Compression Piston. To ESN 199,999. Tier 1

8310T High Compression Piston. To ESN 199,999. Tier 1

8210 High Compression Piston. To ESN 199,999. Tier 1

8400T High Compression Piston. To ESN 199,999. Tier 1

8300 High Compression Piston. To ESN 199,999. Tier 1

8310 High Compression Piston. To ESN 199,999. Tier 1

8520 High Compression Piston. From ESN 200,000. Tier 2.

7710 High Compression Piston. From ESN 200,000. Tier 2.

7810 High Compression Piston. From ESN 200,000. Tier 2.

8120T High Compression Piston. From ESN 200,000. Tier 2.

8220T High Compression Piston. From ESN 200,000. Tier 2.

8320T High Compression Piston. From ESN 200,000. Tier 2.

8420T High Compression Piston. From ESN 200,000. Tier 2.

8120 High Compression Piston. From ESN 200,000. Tier 2.

8520T High Compression Piston. From ESN 200,000. Tier 2.

8220 High Compression Piston. From ESN 200,000. Tier 2.

7820 High Compression Piston. From ESN 200,000. Tier 2.

8320 High Compression Piston. From ESN 200,000. Tier 2.

7920 High Compression Piston. From ESN 200,000. Tier 2.

8420 High Compression Piston. From ESN 200,000. Tier 2.

8330 ILS 9.0 Liter Tier 2 & Tier 3

8430 HDMFWD 9.0 Liter Tier 2 & Tier 3

3520 9.0 Liter Tier 2 & Tier 3

8285R 9.0 Liter Tier 2 & Tier 3

8370R 9.0 Liter Tier 2 & Tier 3

8130 MFWD 9.0 Liter Tier 2 & Tier 3

8330 HDMFWD 9.0 Liter Tier 2 & Tier 3

8235R 9.0 Liter Tier 2 & Tier 3

8430 MFWD 9.0 Liter Tier 2 & Tier 3

8520 9.0 Liter Tier 2 & Tier 3

8295R HDMFWD 9.0 Liter Tier 2 & Tier 3

8370RT 9.0 Liter Tier 2 & Tier 3

8225R 9.0 Liter Tier 2 & Tier 3

8330 ILS 9.0 Liter Tier 2 & Tier 3

8245R 9.0 Liter Tier 2 & Tier 3

8430 9.0 Liter Tier 2 & Tier 3

8130 9.0 Liter Tier 2 & Tier 3

8295R ILS 9.0 Liter Tier 2 & Tier 3

8320T 9.0 Liter Tier 2 & Tier 3

8225R ILS 9.0 Liter Tier 2 & Tier 3

8330 MFWD 9.0 Liter Tier 2 & Tier 3

8245R HDMFWD 9.0 Liter Tier 2 & Tier 3

8530 9.0 Liter Tier 2 & Tier 3

8230 9.0 Liter Tier 2 & Tier 3

8295R MFWD 9.0 Liter Tier 2 & Tier 3

8320RT 9.0 Liter Tier 2 & Tier 3

8225R MFWD 9.0 Liter Tier 2 & Tier 3

8330T 9.0 Liter Tier 2 & Tier 3

8245R ILS 9.0 Liter Tier 2 & Tier 3

8430T 9.0 Liter Tier 2 & Tier 3

8330 9.0 Liter Tier 2 & Tier 3

8295RT 9.0 Liter Tier 2 & Tier 3

8230 HDMFWD 9.0 Liter Tier 2 & Tier 3

8335R 9.0 Liter Tier 2 & Tier 3

8245R MFWD 9.0 Liter Tier 2 & Tier 3

8530 HDMFWD 9.0 Liter Tier 2 & Tier 3

8430 9.0 Liter Tier 2 & Tier 3

8310R 9.0 Liter Tier 2 & Tier 3

8230 ILS 9.0 Liter Tier 2 & Tier 3

8335RT 9.0 Liter Tier 2 & Tier 3

8260R 9.0 Liter Tier 2 & Tier 3

8530 ILS 9.0 Liter Tier 2 & Tier 3

8530 9.0 Liter Tier 2 & Tier 3

8310RT 9.0 Liter Tier 2 & Tier 3

8230 MFWD 9.0 Liter Tier 2 & Tier 3

8345R 9.0 Liter Tier 2 & Tier 3

8270R 9.0 Liter Tier 2 & Tier 3

870G 9.0 Liter Tier 2 & Tier 3

9230 9.0 Liter Tier 2 & Tier 3

8320R 9.0 Liter Tier 2 & Tier 3

8230 9.0 Liter Tier 2 & Tier 3

8345R ILS 9.0 Liter Tier 2 & Tier 3

8270R HDMFWD 9.0 Liter Tier 2 & Tier 3

870GP 9.0 Liter Tier 2 & Tier 3

8130 AT2 ILS 9.0 Liter Tier 2 & Tier 3

8320R MFWD 9.0 Liter Tier 2 & Tier 3

8230T 9.0 Liter Tier 2 & Tier 3

8345R MFWD 9.0 Liter Tier 2 & Tier 3

8270R ILS 9.0 Liter Tier 2 & Tier 3

8360R 9.0 Liter Tier 2 & Tier 3

8130 AT2 MFWD 9.0 Liter Tier 2 & Tier 3

8320RT 9.0 Liter Tier 2 & Tier 3

8330 9.0 Liter Tier 2 & Tier 3

8345RT 9.0 Liter Tier 2 & Tier 3

2854 9.0 Liter Tier 2 & Tier 3

8270R MFWD 9.0 Liter Tier 2 & Tier 3

8360RT 9.0 Liter Tier 2 & Tier 3

8130 ILS 9.0 Liter Tier 2 & Tier 3

8330 HD MFWD 9.0 Liter Tier 2 & Tier 3

JD1220 88mm Bore Non Turbo

JD1200 88mm Bore Non Turbo

JD1400 88mm Bore Non Turbo

约翰迪尔 3029 2.9D 活塞(米) RE61467

|

|

||||||||||||||||||||||||||||||

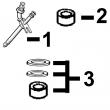

(1) 螺旋式齿轮.

(2) 用法兰的有头螺钉TR85363替换所有的R78558有头螺钉。

(3) 活塞包括活塞销和卡簧.

(4) 组件包含TT20094螺旋形齿轮,可以用于TRE50979的曲轴.

(5) 分离式连杆,请使用零件号TR80033的连杆;断口式连杆,请使用零件号TR501124的连杆。

(6) 断口分离式连杆。