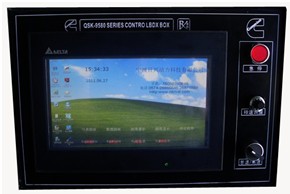

Independent research and development of automatic control system of diesel generators, is made available to the Assembly plant for large diesel generator unit in supporting. Product line covers single, and, since the start of operation units, and can support automatic conversion of AC power (ATS) for rapid boot and switched to diesel generator powered diesel generator set. To provides hotel, and fire, and medical, emergency power of emergency supply, reliable of design and the sound of debugging; has full professional of engineering designers, and personally for debugging, debugging time short, effect excellent; security of line arrangement full in accordance with electric specification; versatility strong, applies Yu Rolls Royce (PERKINS), and Volvo (VOLVO), and Benz (MTU), and large Yu (DAEWOO), and road according to Moskowitz (Deutz), both at home and abroad many different models, and different capacity unit of control;

Function:

Design of control system of automatic control, you can select manual program control, automatic program control, remote control mode.

Can be set to process control of diesel engines, including: pre or pre-lubrication time, initiated delay time, start time, start from the running time, speed, idling speed-speed process time, cooling down time.

Rated engine speed values can be set (non-generator), automatically monitor engine speed in starting, idling, litres, change of speed at full speed, complete start motor input and withdrawal of police, speed, high and low forecast and limit downtime.

Settable alarm limits, overrun pre-alarm automatically (without stopping), alarm and automatic stop.

Prediction of police items including: speed, low speed, low oil pressure, high cooling temperature, high temperature, low temperature (less than 4 ° c), low fuel level, low cooling water level, low battery voltage, battery voltage, higher speed signals are not aligned;

Display function:

Diesel engine running state display: according to the system's actual situation, and displays current status: wait, power, supply oil, startup, startup delay, idle delay time, up and running, cooling down, emergency stop. (Control output on the left side running lights display the current status of the module)

Measurement of diesel engine operating parameters display: during the system operation, displays the current parameter values: speed, cooling, temperature, oil temperature, oil pressure, and by Deputy display page display run timing, fuel quantity, battery voltage.

Diesel engine alarm status display: when the system has a fault alarm, fault of the Panel that appears in the appropriate location, description and alarm type (pre-alarm or alarm), and cause alarm.

Diesel engine parameter setting display: displays the parameter values for the current system settings, including start/stop status settings, speed control with time delay setting and alarm, warning of all parameters to the set value.

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文(简)

中文(简) Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska