Perkins2806发动机水泵检查

Perkins2806发动机水泵检查

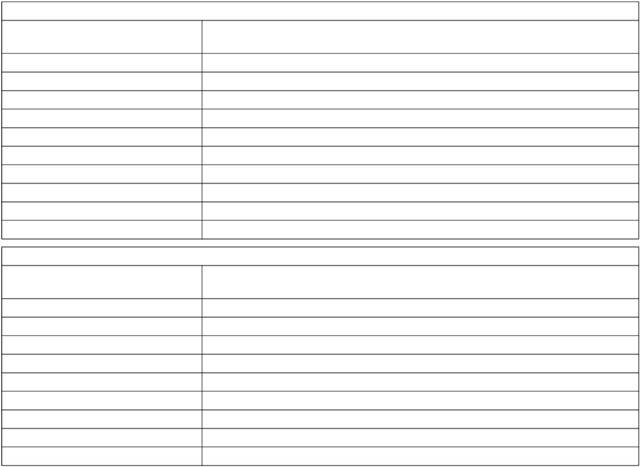

Coolant pump

Shaft diameter at the position of the coolant seal (M) ... ... ... ... ... . 9,0 +/- 0,0 mm (0.7520 +/- 0.0004 in)

![]() 2

2

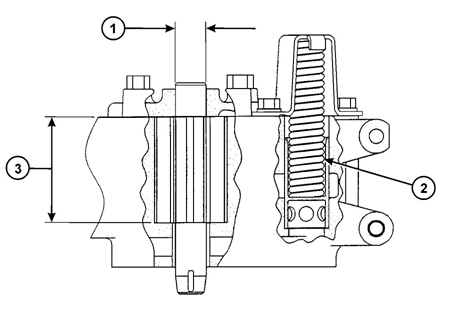

Recommended torque figures

Exceptions to these torque figures are given in the Workshop Manual where necessary.

Before any components are fitted to the engine, ensure that they are in a new or close to new condition. Bolts

or threads mus t not be worn or damaged. Components must be free from rust or other corrosion. Clean with

a non-corrosive cleaner if neces sary. Do not lubricate the threads of fasteners. Rust preventative which has

been applied by the component supplier for shipping and storage is acceptable. Certain components may

require an application of a particular lubricant, details are given in the Workshop Manual where relevant.

Standard torque figures for metric fasteners

Thread size

metric

M6

M8

M0

M2

M4

M6

M20

M24

M0

M6

Thread size

metric

M6

M8

M0

M2

M6

M20

M24

M0

M6

Metric nuts and bolts

Standard torque

2 +/- Nm (9 +/- 2 lbf ft)

28 +/- 7 Nm (2 +/- 5 lbf ft)

55 +/- 0 Nm (4 +/- 7 lbf ft)

00 +/- 20 Nm (75 +/- 5 lbf ft)

60 +/- 0 Nm (20 +/- 22 lbf ft)

240 +/- 40 Nm (75 +/- 0 lbf ft)

460 +/- 60 Nm (40 +/- 44 lbf ft)

800 +/- 00 Nm (590 +/- 75 lbf ft)

600 +/- 200 Nm (80 +/- 50 lbf ft)

2700 +/- 00 Nm (2000 +/- 220 lbf ft)

Metric taperlock studs

Standard torque

8 +/- Nm (6 +/- 2 lbf ft)

7 +/- 5 Nm ( +/- 4 lbf ft)

5 +/- 5 Nm (26 +/- 4 lbf ft)

65 +/- 0 Nm (48 +/- 7 lbf ft)

0 +/- 20 Nm (80 +/- 5 lbf ft)

70 +/- 0 Nm (25 +/- 22 lbf ft)

400 +/- 60 Nm (00 +/- 44 lbf ft)

750 +/- 80 Nm (550 +/- 60 lbf ft)

200 +/- 50 Nm (880 +/- 0 lbf ft)

![]() 2800

2800

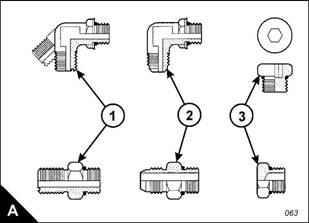

Standard torque figures for imperial fasteners

Thread size

inches

/4

5/6

/8

7/6

/2

9/6

5/8

/4

7/8

/8

/4

/8

/2

Thread size

inches

/4

5/6

/8

7/6

/2

5/8

/4

7/8

/8

/4

/8

/2

Imperial nuts and bolts

Standard torque

2 +/- Nm (9 +/- 2 lbf ft)

25 +/- 6 Nm (8 +/- 4 lbf ft)

47 +/- 9 Nm (5 +/- 7 lbf ft)

70 +/- 5 Nm (50 +/- lbf ft)

05 +/- 20 Nm (75 +/- 5 lbf ft)

60 +/- 0 Nm (20 +/- 22 lbf ft)

25 +/- 40 Nm (60 +/- 0 lbf ft)

70 +/- 50 Nm (275 +/- 7 lbf ft)

620 +/- 80 Nm (460 +/- 60 lbf ft)

900 +/- 00 Nm (660 +/- 75 lbf ft)

00 +/- 50 Nm (960 +/- 0 lbf ft)

800 +/- 200 Nm (20 +/- 50 lbf ft)

2400 +/- 00 Nm (780 +/- 220 lbf ft)

00 +/- 50 Nm (2280 +/- 260 lbf ft)

Imperial taperlock studs

Standard torque

8 +/- Nm (6 +/- 2 lbf ft)

7 +/- 5 Nm ( +/- 4 lbf ft)

5 +/- 5 Nm (26 +/- 4 lbf ft)

45 +/- 0 Nm ( +/- 7 lbf ft)

65 +/- 0 Nm (48 +/- 7 lbf ft)

0 +/- 20 Nm (80 +/- 5 lbf ft)

70 +/- 0 Nm (25 +/- 22 lbf ft)

260 +/- 40 Nm (90 +/- 0 lbf ft)

400 +/- 60 Nm (00 +/- 44 lbf ft)

525 +/- 60 Nm (90 +/- 44 lbf ft)

750 +/- 80 Nm (550 +/- 60 lbf ft)

950 +/- 25 Nm (700 +/- 90 lbf ft)

200 +/- 50 Nm (880 +/- 0 lbf ft)

![]() 2

2

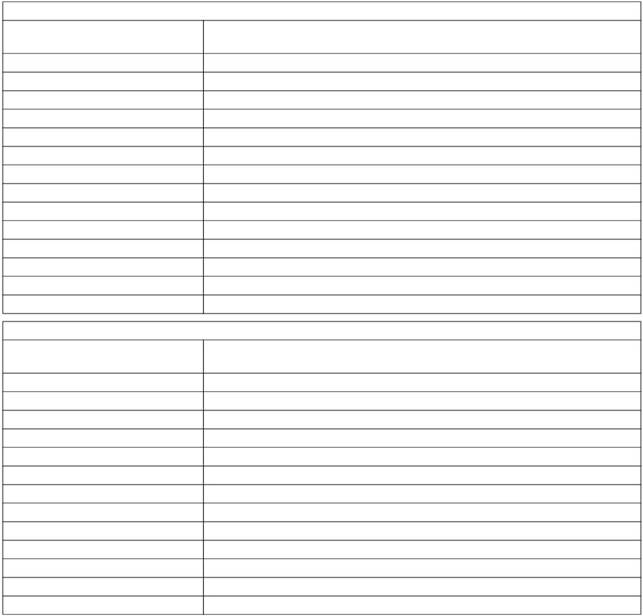

Standard torque figures for ‘O’ ring face seal fittings and 7 degree flared fittings

|

Torque figures for ferrous straight thread ‘O’ ring fittings when connected to ferrous materials | ||

|

Outside diameter of nominal tube |

Thread size Inches |

Standard torque |

|

,8 mm (0.25 in) |

5/6 - 24 |

5,0 +/- ,5 Nm (4 +/- lbf ft) |

|

4,76 mm (0.88 in) |

/8 - 24 |

2 +/- 2 Nm (9 +/- lbf ft) |

|

6,5 mm (0.250 in) |

7/6 - 20 |

22 +/- 2 Nm (6 +/- lbf ft) |

|

7,94 mm (0.2 in) |

/2 - 20 |

0 +/- Nm (22 +/- 2 lbf ft) |

|

9,52 mm (0.75 in) |

9/6 - 8 |

48 +/- 5 Nm (5 +/- 4 lbf ft) |

|

2,70 mm (0.500 in) |

/4 - 6 |

82 +/- 8 Nm (60 +/- 6 lbf ft) |

|

5,88 mm (0.625 in) |

7/8 - 4 |

4 +/- 5 Nm (05 +/- lbf ft) |

|

9,05 mm (0.750 in) |

/6 - 2 |

90 +/- 20 Nm (40 +/- 5 lbf ft) |

|

22,22 mm (0.875 in) |

/6 - 2 |

250 +/- 25 Nm (85 +/- 8 lbf ft) |

|

25,40 mm (.000 in) |

5/6 - 2 |

00 +/- 0 Nm (220 +/- 22 lbf ft) |

|

,75 mm (.250 in) |

5/8 - 2 |

50 +/- 0 Nm (260 +/- 22 lbf ft) |

|

8,0 mm (.500 in) |

7/8 - 2 |

40 +/- 40 Nm (20 +/- 0 lbf ft) |

|

50,80 mm (2.000 in) |

2 /2 - 2 |

450 +/- 45 Nm (0 +/- lbf ft) |

Note: For the table above, use 50 percent of the torque figure when the fitting, the plug or the port material is

nonferrous.

Examples of relevant fittings are shown (A): ‘O’ ring face s eal (A), 7 degree flare (A2) and plug with a

hexagon or socket-type head (A).

![]() 2800

2800

‘O’ ring face seal fittings

|

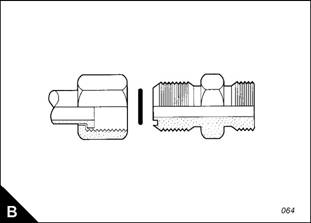

Torque figures for ferrous straight thread ‘O’ ring fittings (B) | |

|

Thread size inches |

Standards torque |

|

/4 |

8 +/- Nm (6 +/- 2 lbf ft) |

|

5/6 |

7 +/- 5 Nm ( +/- 4 lbf ft) |

|

/8 |

5 +/- 5 Nm (26 +/- 4 lbf ft) |

|

7/6 |

45 +/- 0 Nm ( +/- 7 lbf ft) |

|

/2 |

65 +/- 0 Nm (48 +/- 7 lbf ft) |

|

5/8 |

0 +/- 20 Nm (80 +/- 5 lbf ft) |

|

/4 |

70 +/- 0 Nm (25 +/- 22 lbf ft) |

|

7/8 |

260 +/- 40 Nm (90 +/- 0 lbf ft) |

|

400 +/- 60 Nm (00 +/- 44 lbf ft) | |

|

/8 |

525 +/- 60 Nm (90 +/- 44 lbf ft) |

|

/4 |

750 +/- 80 Nm (550 +/- 60 lbf ft) |

|

/8 |

950 +/- 25 Nm (700 +/- 90 lbf ft) |

|

/2 |

200 +/- 50 Nm (880 +/- 0 lbf ft) |

![]() 2

2

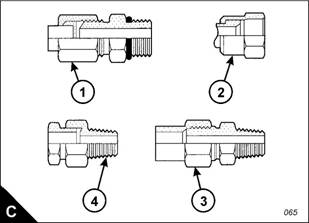

Torque figures for flared and ‘O’ ring fittings

The torque figures given in the table below and the table given on page 7 should be applied to the nut of the

fittings whic h follow: 7 degree flared fittings (C), 45 degree flared fittings (C), inverted flared fittings (C2),

‘O’ ring fittings for a recessed drive, ‘O’ ring fittings for air conditioning and swivel nuts (C2). The figures should

be used for applications which allow these working pressures: 7750 to 4450 kPa (25 to 5000 lb/in²). The

torque figure depends on the size and type of fitting.

|

Nuts for 7 degree flared fittings | ||

|

Outside diameter of nominal tube |

Thread size Inches |

Standard torque |

|

,8 mm (0.25 in) |

5/6 |

5,0 +/- ,5 Nm (4 +/- lbf ft) |

|

4,76 mm (0.88 in) |

/8 |

+/- 2 Nm (8 +/- lbf ft) |

|

6,5 mm (0.250 in) |

7/6 |

6 +/- 4 Nm (2 +/- lbf ft) |

|

7,94 mm (0.2 in) |

/2 |

20 +/- 5 Nm (5 +/- 4 lbf ft) |

|

9,52 mm (0.75 in) |

9/6 |

25 +/- 5 Nm (8 +/- 4 lbf ft) |

|

9,52 mm (0.75 in) |

5/8 |

5 +/- 5 Nm (26 +/- 4 lbf ft) |

|

2,70 mm (0.500 in) |

/4 |

50 +/- 7 Nm (7 +/- 5 lbf ft) |

|

5,88 mm (0.625 in) |

7/8 |

65 +/- 7 Nm (48 +/- 5 lbf ft) |

|

9,05 mm (0.750 in) |

/6 |

00 +/- 0 Nm (75 +/- 7 lbf ft) |

|

22,22 mm (0.875 in) |

/6 |

20 +/- 0 Nm (90 +/- 7 lbf ft) |

|

25,40 mm (.000 in) |

5/6 |

5 +/- 5 Nm (00 +/- lbf ft) |

|

,75 mm (.250 in) |

5/8 |

80 +/- 5 Nm (5 +/- lbf ft) |

|

8,0 mm (.500 in) |

7/8 |

225 +/- 5 Nm (65 +/- lbf ft) |

|

50,80 mm (2.000 in) |

2 /2 |

20 +/- 0 Nm (240 +/- 22 lbf ft) |

Note: For the table above, use 50 percent of the torque figure when the fitting, the plug or the port material is

nonferrous.

| ||||||||||||||||||||||||||||||||||||||||

45 degree flared and 45 degree inverted flare fittings

|

45 degree flared and 45 degree inverted flare fittings | ||

|

Outside diameter of nominal tube |

Thread size Inches |

Standard torque |

|

,8 mm (0.25 in) |

5/6 |

5,0 +/- ,5 Nm (4 +/- lbf ft) |

|

4,76 mm (0.88 in) |

/8 |

8 +/- ,5 Nm (6 +/- lbf ft) |

|

6,5 mm (0.250 in) |

7/6 |

+/- 2 Nm (8 +/- lbf ft) |

|

7,94 mm (0.2 in) |

/2 |

7 +/- Nm ( +/- 2 lbf ft) |

|

9,52 mm (0.75 in) |

5/8 |

0 +/- Nm (22 +/- 2 lbf ft) |

|

, mm (0.48 in) |

/6 |

0 +/- Nm (22 +/- 2 lbf ft) |

|

2,70 mm (0.500 in) |

/4 |

8 +/- 4 Nm (28 +/- lbf ft) |

|

5,88 mm (0.625 in) |

7/8 |

50 +/- 5 Nm (7 +/- 4 lbf ft) |

|

9,05 mm (0.750 in) |

/6 |

90 +/- 8 Nm (65 +/- 6 lbf ft) |

|

22,22 mm (0.875 in) |

/4 |

00 +/- 0 Nm (75 +/- 7 lbf ft) |

Tapered pipe thread fittings

Thread size

Note: For the table above, use 50 percent of the torque figure when the fitting, the plug or the port material is

nonferrous.

![]() 2

2

Torque figures for standard hose clamps of the worm drive band type

|

Width of clamp |

Torque figure for initial installation on a new hose |

|

7,9 mm (0. in) |

0,9 +/- 0,2 Nm (8 +/- 2 lbf in) |

|

,5 mm (0.5 in) |

4,5 +/- 0,5 Nm (40 +/- 4 lbf in) |

|

5,9 mm (0.6 in) |

7,5 +/- 0,5 Nm (65 +/- 4 lbf in) |

|

Width of clamp |

Torque figure for used clamp |

|

7,9 mm (0. in) |

0,7 +/- 0,2 Nm (6 +/- 2 lbf in) |

|

,5 mm (0.5 in) |

,0 +/- 0,5 Nm (27 +/- 4 lbf in) |

|

5,9 mm (0.6 in) |

4,5 +/- 0,5 Nm (40 +/- 4 lbf in) |

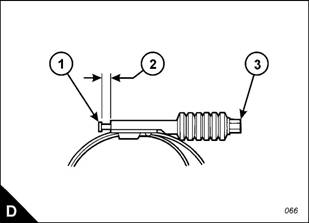

Torque figures for const ant torque hose clamps

Use a torque wrenc h for the correct installation of a constant torque hose clamp. For a constant torque hose

clamp to be installed correctly, these conditions must exist:

The screw tip (D) must extend by 6,5 mm (0.250 in) beyond the housing (D2).

The belleville washers must be collapsed almost flat after the screw (D) has been tightened to a torque of

+/- Nm (98 +/- 9 lb in).

400-100-8969 15088860848

0574-26871589 15267810868

0574-26886646 15706865167

0574-26871569 18658287286

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文(简)

中文(简) Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska