帕金斯柴油发动机曲轴总成的维修安装标准技术参数3012

帕金斯柴油发动机曲轴总成的标准技术参数3012

General description

一般描述

The crankshaft is made from a forging of chromium

曲轴是用铬合金锻造的

molybdenum steel. It is nitrided on all surfaces except

钼钢。这是所有表面除氮化

the tapped holes, the hole for the dowel and the end

的螺纹孔,用于定位和端孔

faces at the front and the rear. The correct balance is

前方和后方的面孔。正确的平衡是

obtained when the crankshaft is machined, and there

在曲轴加工时得到的

is no requirement for further compensation when

无需进一步补偿的要求

assembled.

组装。

The 13 bearing s urfaces consist of seven main

13轴承有主要包括七

journals and six crank pins. Each crank pin holds two

期刊和六个曲柄销。每个曲柄销有2个

connecting rods.

连接杆。

The crankshafts of engines manufactured up to build

Perkins3012发动机曲轴制造的建立

number 970209 have an oil reservoir in each crank

号970209在每个曲柄有一个油气藏

pin. Access to clean each reservoir is provided by a

销。每一个水库的清洁通道由一个

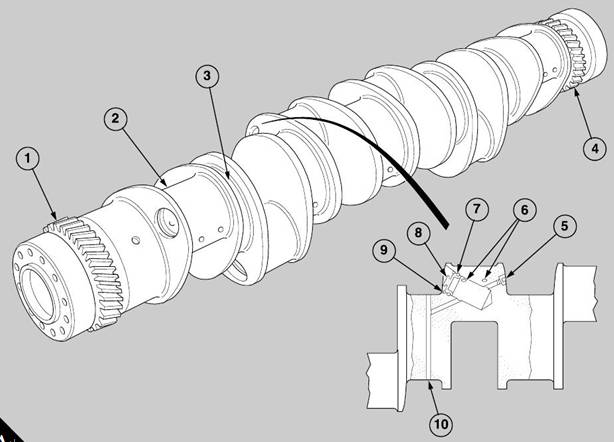

steel plug (A8) which is retained by a s pring clip (A9).

钢塞(A8)是由一个弹簧夹保留(A9)。

The crankshafts of engines from build number

从建号Perkins3012发动机曲轴

970209 have an arrangement of passages which

970209有一个通道的安排

removes the requirement for oil reservoirs.

消除对油气藏的要求。

A helical gear (A1) with 45 teeth is machined around

斜齿轮(A1)45齿加工在

the front end of the crankshaft. The gear drives the

曲轴的前端。齿轮传动

lubricating oil pump through an idler gear. The face at

润滑油泵通过一个中间齿轮。面对

the front end is drilled and tapped for 12 equally

前端被钻,并为12个相同的抽头

spaced bolts, which retain the vis cous damper and

间隔螺栓,保持粘性阻尼器

the multiple groove pulley for the fan drive belts.

风扇传动带的多槽皮带轮。

The main bearings have steel backs with bearing

主轴承有轴承钢背

surfaces of lead bronze. The bearing surfaces have

铅青铜表面。轴承表面有

a fine top lay er of lead indium.

一个精细的铅铟铟。

The upper half of each bearing has a central groove

每个轴承上一半有一个中央沟

for oil around the inner surface. A hole is drilled in the

内表面的油。钻了一个洞

centre of the groove and is aligned with a hole in the

槽的中心,并与孔在

crankcase which supplies the oil.

提供机油的曲轴箱。

The lower halves of the bearings do not have

轴承的下半部没有

grooves.

槽。

One end of each half bearing has a location tag which

每个一半的一端有一个位置标记

is pressed away from one edge. The tags fit in

被压离一边。标签适合于

recesses which are machined in the crankcase and in

凹槽,在曲轴箱和加工

the bearing caps.

轴承盖。

The thrust washers have steel backs with faces of

止推垫圈有钢背的

lead bronze. They are made in two halves which are

铅青铜。他们是在两半,这是

interchangeable. Each half has a location tag at one

可互换。每个一半有一个位置标记在一个

end. The upper halves are fitted in recesses which

结束。上半场被安装在凹槽中

are machined in the crankcase on each side of the

被加工在曲轴箱的每一边

central main journal; the lower halves are fitted in

中央的主要杂志;在下半部

recesses which are machined in the bearing cap.

凹槽,在轴承盖加工。

Lubricating oil is supplied from the central main

润滑油是从中央主供应的

bearing across the face of each washer, in which

在每一个洗衣机的脸上,在

grooves are machined to assist the flow of oil.

槽的加工,以协助流动的石油。

Crankshaft

曲轴

To remove

删除

1 Fit the engine in the build stand, operation 16-1.

1安装Perkins3012发动机在建站,运行16-1。

2 Remove the fan adaptor and the front mountings,

2拆下风扇接头和前支架,

operation 21-10.

操作21-10。

3 Remove the flywheel and the flywheel housing,

3拆下飞轮和飞轮壳,

operation 22-4.

操作中可以看到。

4 Remove the timing case and the timing gears,

4拆下定时和定时齿轮,

operation 15-5.

运行5。

5 Remove the lubricating oil sump, operation 19-1 or,

5拆下油池润滑,运行19-1或,

for new engines, operation 19-5.

新的引擎,运行19-5。

6 For early engines, remove the sump adaptor,

6为早期的Perkins3012发动机,拆卸油底壳适配器,

operation 19-3.

操作19-3。

7 Remove the lubricating oil pump, operation 19-7.

7去除润滑油泵,手术197。

8 Turn the crankshaft until one of the pistons of ’A’

8把曲轴拐到一个'一个'

bank is at the bottom of its stroke and remove the four

银行是在它的底部,并删除四

nuts of the big end bearing. Withdraw the bearing cap

大端轴承螺母。取下轴承盖

with the bearing. Fit the guide pin, 21825 843, on to

与轴承。安装导向销,843 21825

one of the bolts of the big end.

大底的一个螺栓。

9 Push the assembly of the piston and the connecting

9推动活塞与连杆的装配

rod into its bore to the end of its stroke. Push carefully

杆成孔,以其行程结束。小心推

to prevent damage to the top of the piston and the

为了防止损坏活塞顶部和

valves.

阀门。

10 Similarly, repeat the operation for the remainder of

10类似的,重复的操作,其余的

the assemblies. Move the guide pin as necessary.

组件。必要时将导针移动。

11 Turn the crankcase for acc ess to the big end

11转ACC ESS的大端曲轴箱

bearings of ’B’ bank. Repeat the operation for the

'乙'银行轴承。重复该操作

assemblies of pistons and connecting rods, as for ’A’

活塞和连杆组件,如“一”

bank.Loosen all the bolts that retain the main bearing

银行:松开主轴承的所有螺栓

caps. Release and remove the side bolts.

帽。松开并拆下侧螺栓。

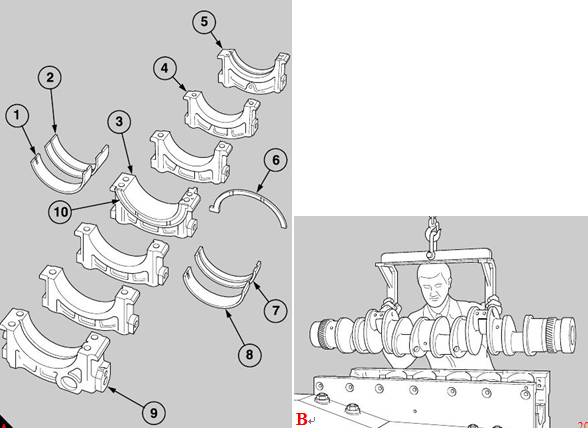

12 Remove the bolts from each main bearing cap and

12从各主轴承盖上拆下螺栓

remov e the caps. If necessary use the slide hammer,

除去瓶盖。如有必要,使用该滑动锤,

21825 849, with the remover tool, 21825 858, to

849 21825,用卸妆工具,858 21825,到

withdraw each main bearing cap (A3,4,5,9) and its

提取各主轴承盖(a3,4,5,9)及其

lower half bearing (A1,8). When the central main

下半轴承(a1,8)。当中央主

bearing cap (A3) is removed, remove also the lower

轴承盖(A3)被删除,删除也较低

halves of the thrust washers (A10).

一半的推力垫圈(A10)。

13 Slide the upper halves of the thrust washers (A6)

13滑动的止推垫圈上半部(A6)

from their recesses around the central main journal.

从凹槽围绕中央的主要期刊。

Use the lift adaptor VP 666 to lift the crankshaft from

使用电梯适配器副总裁666提高曲轴从

the crankcase and put it on wooden vee blocks.

曲轴箱放在木制的V型块。

Remove the upper halves of the main bearings (A2,7)

拆下主轴承上瓦(a2,7)

from the crankcase and also the upper halv es of the

从曲轴箱和也的上的ES

thrust washers.

止推垫圈。

To fit

适合

1 Check for dirt and debris in the passages for the

1检查通道内的污垢和碎片

engine lubricating oil of the crankcase, and also of the

Perkins3012发动机润滑油的曲轴箱,以及

front and the rear main bearing caps (A5,9). Clean

前、后主轴承盖(a5,9)。清洁

thoroughly the bearing housings and the bearing

彻底的轴承座和轴承

caps, and also the main journals and the crank pins of

帽,以及主要期刊和曲柄销

the crankshaft.

曲轴。

2 Check also for dirt and debris in the passages of the

2检查在通道中的污垢和碎片

connecting rods and clean thoroughly the bearing

连接杆和清洁轴承

surfaces of the big ends.

大的末端表面。

3 Ensure that the half bearings and the thrust

3确保半轴承和推力

washers for the main journals of the crankshaft are

曲轴主要期刊的垫圈

absolutely clean, and fit the upper half bearings into

绝对干净,并配合上半轴承

their housings in the crankcase. Give a full

他们的外壳在曲轴箱。充分

application of clean engine lubricating oil to all of the

洁净Perkins3012发动机润滑油在所有的应用

bearing surfaces.

轴承表面。

4 Also, apply clean engine lubricating oil to lubricate

4、应用清洁Perkins3012发动机润滑油润滑

fully the main journals of the crankshaft. Use the lifting

曲轴的主要期刊。使用升降

beam VP 666 to lower the crankshaft into the

梁副总裁666降低曲轴到

crankcase (B). Ensure that the 16 tapped holes in the

曲轴箱(乙)。确保16个孔在

end face of the c rankshaft are furthest from the build

该曲轴端面远的建立

stand, and are at the end of the crankcase to which

站,并在曲轴箱的末端

the timing case is fitted.

安装时的情况。

5 Apply engine lubricating oil to the upper halves of

5将Perkins3012发动机润滑油应用于上半部

the thrust washers and insert them into their recesses

止推垫圈和插入的凹槽

on each side of the central main bearing. Ensure that

在中央主轴承的每一面。确保

the face of lead bronze on each washer is toward the

每一个洗衣机上的铅青铜都是朝着

crankshaft web.

曲轴网。

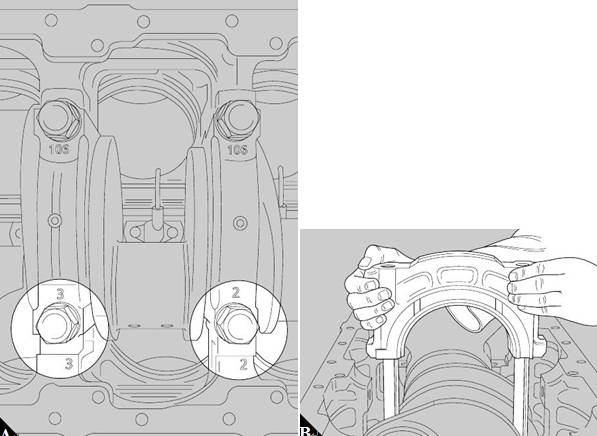

6 Fit the lower halves of the main bearings into the

6将主轴承的下半部配合成

bearing caps and give a full application of clean

轴承盖,并提供一个完整的应用程序的清洁

engine lubricating oil to all of the bearing surfaces. Fit

Perkins3012发动机润滑油对所有轴承表面。适合

all the ass emblies of the bearing caps except the

所有的驴总成轴承盖的外

bearing cap for the central main bearing. Ensure that

主轴承盖轴承盖。确保

the numbers which are stamped on each bearing cap,

每个轴承盖上盖的数字,

to give its relationship, match the numbers which are

给它的关系,匹配的数字是

stamped on the crankcase, as shown (A).

在曲轴箱上加盖,如图所示(一)。

7 Apply a minimum amount of grease to the recesses

7将少量润滑脂的深处

at the sides of the bearing cap for the central main

在中央主轴承盖的两侧

bearing and insert the lower halves of the thrust

轴承和插入的下半部的推力

washers into the recesses. Ensure that the face of

垫圈到深处。确保脸上

lead bronze on each washer is away from the bearing

每个洗衣机上的铅青铜都是远离轴承的

cap.

帽。

8 Fit carefully the assembly of the bearing cap for the

8小心装配轴承盖的装配

central main bearing. Ensure that the halves of the

中心主轴承。确保一半的

thrust washers remain in their positions during the

止推垫圈保持在其位置

operation.

操作。

9 Apply engine lubricating oil to the threads, and

9将Perkins3012发动机润滑油应用于螺纹

under the heads, of the main bolts which retain the

在头下,主螺栓,保留

main bearing caps. Fit carefully each bolt into its

主轴承盖。小心地每一个螺栓安装到它的

location. Do NOT allow the bolts to fall into the holes

位置。不要让螺栓掉到洞

because the threads could be damaged. Insert fully

因为线程可能会损坏。完全插入

each main bolt by hand only.

每一个主螺栓只手。

Caution: On new engines, the bolts fitted to the front,

警告:在新的Perkins3012发动机上,螺栓安装在前面,

centre and rear bearing caps, are different and are

中心和后轴承盖,是不同的,是

fitted with hardened washers. Ensure that the special

配有硬化垫圈。确保特殊

washers are fitted to the bolts before the bolts are

在螺栓前,垫圈安装在螺栓上

fitted to the engine. Do NOT fit any other type of

装在Perkins3012发动机上。不适合任何其他类型的

washer.

洗衣机。

Caution: If a new front, centre or rear bearing cap is

警告:如果一个新的前端,中心或后轴承盖

fitted, do NOT fit the old type of bolts. The new bolts

装,不适合旧型螺栓。新的螺栓

and special washers MUST be used.

必须使用专用垫圈。

10 Apply engine lubricating oil to the threads, and

10将Perkins3012发动机润滑油应用于螺纹

under the heads, of the side bolts which hold rigidly

在头下,用刚性的螺栓

the main bearing caps. Fit the plain washers on the

主轴承盖。安装平垫圈在

M16 bolts and the ’Dowty’ sealing washers on the

M16螺栓和“顶”上的密封垫圈

M14 bolts. Insert fully each bolt, by hand, through the

M14螺栓。用手插入完全的每一个螺栓

side walls of the crankcase.

曲轴箱侧壁。

11 Check that the faces which are machined on the

11检查被加工的面

front and the rear of each main bearing cap are

每一个主轴承盖的前部和后部

aligned with the faces in the crankcase. Tighten

与曲轴箱中的面对齐。拧紧

lightly all of the main bolts and then all of the side

所有的主螺栓,然后所有的侧

bolts.

螺栓。

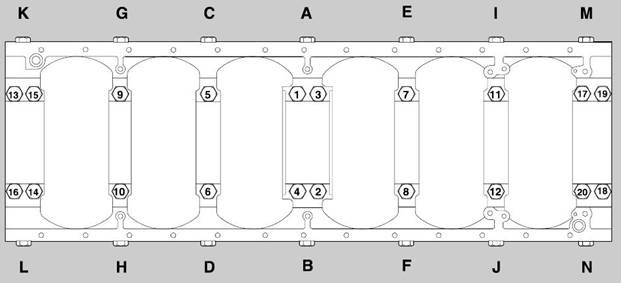

12 Tighten, in the sequence shown in page 86/B, all

12拧紧,在86页/二页所示的序列中

the main bolts of the bearing caps by increments of 50

主轴承盖的螺栓由50的增量

Nm (37 lbf ft) until the maximum torque of 177 Nm

nm(37磅英尺)到177牛米的最大扭矩

(130 lbf ft) is applied. At the end of this phase of the

(130磅英尺)的应用。在这个阶段结束

operation, the main bolts of the main bearing caps at

操作时,主轴承盖的主螺栓

the front, at the c entre and at the rear are tightened

前,在中心和后部紧固

fully.

充分。

Caution: Check frequently that the crankshaft can

警告:经常检查曲轴

rotate freely while the bolts are tightened.

当螺栓紧固时可自由旋转。

13 Continue to tighten the bolts - numbers 5 to 12 (B)

13继续拧紧螺栓-数字5至12(乙)

- for the remainder of the main bearing caps, until the

-对于主轴承盖的其余部分,直到

maximum torque of 488 Nm (360 lbf ft) is applied.

最大扭矩488牛米(360磅英尺)的应用。

14 Tighten all the side bolts, in alphabetical

14按字母顺序拧紧所有螺栓

sequence, until a maximum torque of 114 Nm (85 lbf

序列,直到最大扭矩114牛米(85磅

ft) is applied. At the end of this phase of the operation,

英国金融时报)。在这一阶段的操作结束,

the side bolts of the front, central and rear main

前、中、后主侧螺栓

bearings are tightened fully.

轴承紧固充分。

15 Continue to tighten the remainder of the side bolts

15继续拧紧侧螺栓的剩余部分

- letters C to J (B) - in alphabetical sequence, until a

•以字母顺序排列的字母,直到一

maximum torque of 177 Nm (130 lbf ft) is applied.

最大扭矩177牛米(130磅英尺)的应用。

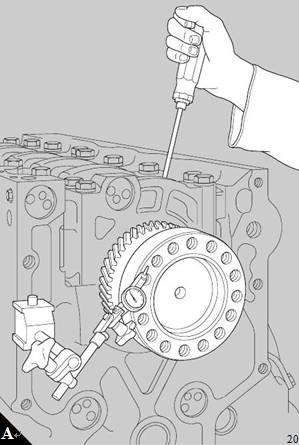

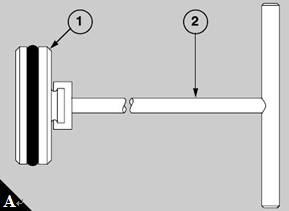

16 Put a dial test indicator with a magnetic base on

16将一个拨号测试指标与磁性基础

the end face of the crankcase. Set the button of the

曲轴箱的端面。设置按钮的

dial test indicator on the end of the crankshaft (A).

曲轴(一)结束时的刻度盘测试指示器。

Use a lever to move the crankshaft backward and

使用杠杆向后移动曲轴

forward against the thrust washers and check the

向前逆止推垫圈和检查

readings on the dial test indicator. Permissible end-

表盘测试指示器读数。允许结束—

float is 0,10 to 0,30 mm (0.004 to 0.012 in).

浮动是10到30毫米(0.004到0.012)。

Turn the crankcase in the build stand so that the ’A’

将曲轴箱在支架上转动,以便“一”

bank cylinders are horizontal. Fit each of the

银行气缸水平。适合每一个

connecting rods, of the ’A’ bank cylinders, to their

连接杆,“一”的银行缸,对他们的

respective crank pins, operation 13-3.

各自的曲柄销、运营13-3。

17 When all of the ’A’ bank connecting rods have

17当所有的'一'银行连接杆有

been fitted, turn the build stand until the ’B’ bank

已装上,把建立架,直到'乙'银行

cy linders are horizontal and use the same procedure

CY该是水平的,使用相同的程序

to fit the connecting rods of the ’B’ bank.

以适应'乙'银行的连接杆。

18 Set a dial test indicator as shown (page 67/B) and

18设置拨号测试指标如显示(页67 /乙)和

check the end float of each big end. The permissible

检查每一个大底的结束浮动。允许

end float is 0,2 to 0,4 mm (0.008 to 0.016 in).

端浮0,2 0.4%毫米(0.008到0.016)。

19 Ensure that the crankshaft turns freely.

19确保曲轴转动自如。

20 Fit the lubricating oil pump, operation 19-7.

20适合的润滑油泵,运行197。

21 For early engines, fit the sump adaptor, operation

21早期的Perkins3012发动机,安装油底壳接头,操作

19-3.

19-3。

22 Fit the lubricating oil sump, operation 19-1 or, for

22合适的润滑油,操作或为19-1,

new engines, operation 19-5.

新的引擎,运行19-5。

23 Fit the timing case and the timing gears, operation

23配合正时情况及正时齿轮、操作

15-5.

15-5。

24 Fit the flywheel and the flywheel housing,

24配合飞轮和飞轮壳,

operation 22-4.

操作中可以看到。

25 Fit the fan adaptor, operation 21-10.

25安装风扇接头,操作21-10。

26 Remove the engine from the build stand,

26从建造支架上拆下Perkins3012发动机,

operation 16-1.

操作16-1。

To dismantle and to assemble

拆卸和组装

1 Press down each plug (A1) of the reservoirs and

1按下每个插头(A1)的水库

release the circlips. Fit the remover/replacer,

松开卡环。安装器/替代品,

27610005 (A2), on the s pigot of the plug and withdraw

27610005(A2),在插头的Pigot和退出

the plug. Early engines are fitted with a different type

插头。早期的Perkins3012发动机安装有不同的型号

of plug which has a threaded hole, for these engines

对这些Perkins3012发动机有一个螺纹孔的插头

use remove/replacer, 21825 859, together with the

使用删除/替换,21825 859,加

slide hammer, 21825 849. Clean all the components

滑动锤,849 21825。清洁所有的部件

with a degreasing solution.

用脱脂液。

To assemble

组装

1 Fit new ’O’ ring seals to the blanking plugs of the

1配合新的“O”环密封件的消隐插头

reservoirs. In sequence, apply a small amount of

水库。按顺序,申请少量

’Stantyte’ lubricant or ’Morris’s liner lubricant’ around

“stantyte润滑或润滑油在莫里斯的衬垫

the complete circumference of each housing in the

在每个住房的完整周长

crankshaft. Press fully each plug into its housing and

曲轴。每一个插头插入到它的外壳和

fit the circ lip into its recess in the housing. Use the

将中国保监会的唇装进住房的凹部。使用

relevant remover/replacer to pull backward the plug

相关器/替代品后拉插头

4 Check for damage on the front and rear faces at the

4检查前部和后部的损坏

ends of the crankshaft. Als o check for small marks on

曲轴的末端。还检查小标志

the circumferences which are the location faces for

这是定位面圆周

the flywheel and the pulley .

飞轮和皮带轮。

5 If the crankshaft is usable, small marks can be

5如果曲轴是可用的,小的标记可以

removed from the journals, the crank pins, the thrust

从杂志上删除,曲柄销,推力

faces and the locations on the ends by the use of a

用一个面和地点在两端

very fine grade of oil stone.

非常精细的石油石级。

Main bearings and thrust washers

主轴承和止推垫圈

against the circlip.

对卡簧。

To clean

清洁

1 Wash thoroughly the oil holes and reservoirs of the

1彻底清洗油孔和水库

crankshaft with kerosene and dry with compressed

带有煤油和干燥的曲轴

air. Ensure that all surfaces of the crankshaft are

空气。确保曲轴的所有表面都是

cleaned thoroughly.

彻底清洗。

To inspect

检查

1 Hold the shaft in suitable wooden blocks under

1在适当的木板块下把轴抓住

main journals nos. 1 and 7. Check for crac ks in the

主要期刊编号1和7。检查裂缝的

crankshaft, by the electro-magnetic method if

曲轴,采用电磁法

possible.

可能的。

2 Check for damage and small marks on the main

2检查主要的损坏和小标记

journals, crank pins and thrust faces; check for ovality

期刊,曲柄销和止推面;检查椭圆度

the journals and crank pins. Refer to Perkins Engines

期刊和曲柄销。指帕金斯Perkins3012发动机

Company Limited, Shrewsbury, for the instructions

什鲁斯伯里有限公司,为本指令

S.R.S. 121 Issue 2 for the repair of worn or damaged

121期为2 s.r.s.磨损或损坏的修复

journals and crank pins .

期刊与曲柄销。

3 Hold the crankshaft in ’V’ blocks under the main

3将曲轴在主的“五”块下

journals nos. 1 and 7 and check the amount of

期刊编号1和7,检查数量

deflection at the central main journal. The permissible

在中央主刊上的挠度。允许

amount of the deflection, which is given on page 89,

的偏转量,这是在89页,

must be gradual along the length of the crankshaft.

曲轴的长度必须是渐进的。

1 Remove the c rankshaft, operation 14-4.

1拆下曲轴,操作14-4。

2 Check for wear, cracks and contamination in the

2检查磨损,裂纹和污染

surfaces of the bearings. Renew bearings as a set if

轴承表面。如果更新轴承

it is possible that a bearing will not complete a further

这是可能的,一个轴承将不能完成一个进一步的

full period of service.

全程服务。

3 Check the thickness of the thrust washers.

3检查止推垫圈的厚度。

Nominal dimensions for new thrust washers are:

新止推垫圈的公称尺寸:

2,93 to 3,0 mm (0.116 to 0.118 inch)

2,93至3毫米(0.116到0.118英寸)

New thrust washers must be fitted if there is wear on

新的止推垫圈必须安装在有磨损的

the thrust fac es and also if the crankshaft has

推力面,如果曲轴

excessive end-float.

过多终漂。

Fits and clearances

配合与间隙

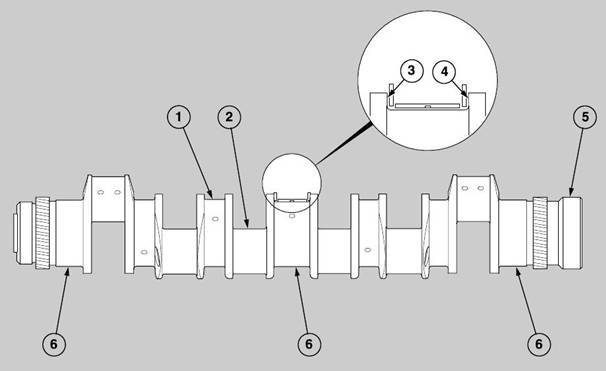

Crankshaft journals

曲轴轴颈

Diameter (A1)145,975 to 146,000 mm (5.7470 to

直径(A1)145975至146000毫米(5.7470

5.7480 in)

5.7480)

Permissible worn dimensions145,910 mm (5.7445 in)

允许穿dimensions145910毫米(5.7445英寸)

Ovality - permissible worn dimensions0,076 mm

椭圆-允许穿dimensions0076毫米

(0.0030 in)

(0.0030)

Journals in main bearings – clearance0,076 to 0,145

在主轴承–clearance0076期刊0145

mm (0.0030 to 0.0057 in)

毫米(0.0030至0.0057英寸)

Crank pins

曲柄销

Diameter (A2)97,978 to 98,000 mm (3.8574 to 3.8583

直径(A2)97978至98000毫米(3.8574至3.8583

in)

在)

Diameter - permissible worn dimensions97,914 mm

dimensions97914毫米直径允许磨损

(3.8548 in)

(3.8548)

Ovality - permissible worn dimensions0,076 mm

椭圆-允许穿dimensions0076毫米

(0.0030 in)

(0.0030)

Deflection of crankshaft

挠曲轴

Deflection of crankshaft (A6) when it is held in

挠曲轴(A6)时举行

'V' blocks under nos. 1 and 7 main journals0,1000 mm

V形块在1号和7个主要journals01000毫米

(0.0039 in)

(0.0039)

(Deflection must be gradual from outer main journals

(挠度必须是从外主要期刊逐渐的

to central main journal)

到中央主杂志)

End float of crankshaft

曲轴端浮

Width between crankshaft webs of central journal

轴颈之间的宽度

(A3)81,43 to 81,48 mm (3.2059 to 3.2079 in)

(A3)81,43到81,48毫米(3.2059到3.2079)

Width of central bearing (A4) across thrust washers

中心轴承宽度(A4)在止推垫圈

81,15 to 81,30 mm (3.1949 to 3.2008 in)

81,15到81,30毫米(3.1949到3.2008)

Clearanc e (new)0,13 to 0,33 mm (0.005 to 0.013 in)

清除率E(新)0,13到0,33毫米(0.005到0.013)

Permissible worn clearance0,483 mm (0.019 in)

允许穿clearance0483毫米(0.019英寸)

Flywheel on crankshaft

曲轴飞轮

Bore of flywheel160,000 to 160,025 mm (6.2992 to

口径160025毫米(6.2992 flywheel160000

6.3002 in)

6.3002)

Diameter of crankshaft (A5)159,961 to 159,986 mm

直径曲轴(A5)159961至159986毫米

(6.2976 to 6.2986 in)

(6.2976至6.2986)

Clearance (new)0,014 to 0,064 (0.0006 to 0.0026)

通关(新)0014至0064(0.0006至0.0026)

400-100-8969 15088860848

0574-26871589 15267810868

0574-26886646 15706865167

0574-26871569 18658287286

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文(简)

中文(简) Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska