Perkin柴油发动机3012正时齿轮和辅助传动系统

Perkin柴油发动机3012正时齿轮和辅助传动系统

The timing gears (A) of the engine are protected by a

《定时速(A)的Perkins3012发动机是由A

housing at the rear of the engine which has two

房屋的背面的Perkins3012发动机,已经有两个

components, the timing case and the flywheel

组件的实例,定时和飞轮

housing.

住房。

The timing case is made from heavy-duty cast iron

这样的案例是从定时重防腐铸铁

and is bolted to the rear end of the crank case. It has

鸭子的背栓接冰比曲柄的案例。它具有

mountings for the connection block for the spill fuel,

mountings的连接块的溢出的燃料。

the starter motor and the coolant pump. It holds the

《coolant起动电机和泵。《IT团队

inner bearing, and the housing for the oil seal, of the

内轴承和住房的油密封的

auxiliary drive shaft.

辅助驱动轴。

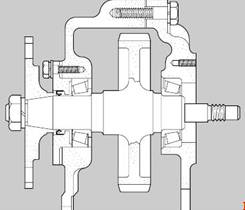

For early engines, the oil seal of the auxiliary drive

早期的Perkins3012发动机,油密封的操作。

shaft is s eparate and is pressed into its housing. The

轴的eparate冰和冰。到它的房屋。《

current engine has a housing with an integral oil seal.

Perkins3012发动机有一个电流积分的住房和油密封。

The housing also has an ’O’ ring in a groove around

住房也有个“O型圈在一个槽。

its spigot to seal the bore in the timing case.

它的两个密封的承钻的定时的案例。

The fly wheel housing is also made from heavy-duty

住宅的平面的车轮从冰也太重防腐

cast iron and is bolted to the timing case. It holds the

铸铁和冰定时栓接两个案例。《IT团队

outer bearing for the end of the aux iliary drive shaft

外轴承的辅助iliary比的传动轴

and has a mounting for the fuel lift pump. The correct

有一个mounting和燃料泵的提升。《正确

location of the assembly is ensured by a large dowel

装配位置的冰ensured市一大dowel

and the axles of the idler gears in the timing case.

和从动轮的轴速的定时的案例。

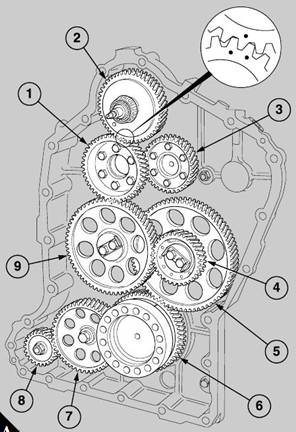

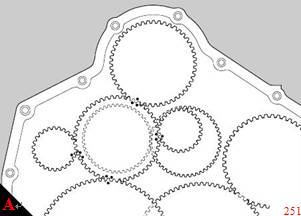

The arrangement of the timing gears consists of the

《安排》报由定时齿轮

drive gear on the crankshaft (A6), the idler gear (A7)

驱动齿轮的曲轴(A6)、《齿轮从动轮(A7)

for the drive to the gear of the coolant pump (A8), the

这两个驱动齿轮泵的coolant(A8)。

double idler gear (A4,5), the main idler gear (A9), the

双齿轮从动轮(a4,5)的主、从动轮齿轮(A9),

drive gear for the fuel injection pump/camshafts (A1),

传动齿轮的燃料喷射泵/ camshafts(A1)

the two camshaft gears (A3) and the aux iliary drive

《camshaft双速(A3)和辅助iliary驱动

gear (A2). The drive gear for the fuel injection pump/

齿轮(A2)。在驱动齿轮的燃料喷射泵/

camshafts is bolted to the outer face of the camshaft

camshafts冰的栓接面外的camshaft

gear of ’B’ bank.

齿轮的B银行。

The axles of the idler gears are bolted to the rear end

从动轮的轴的速度是比背栓接。

of the crankcase and the end float of each gear is

“crankcase and the of each齿轮比浮冰块

limited by the thrust washers.

公司的止推垫圈。

There are timing marks on the drive gear of the

有时间的痕迹在传动齿轮的

crankshaft, the double idler gear, the main idler gear,

曲轴的双齿轮从动轮,主、从动轮的齿

the drive gear for the fuel injection pump/camshafts,

在驱动齿轮的燃料喷射泵/ camshafts,

the two camshaft gears and the auxiliary drive gear.

《camshaft双速和辅助传动齿轮。

The use of the timing marks ensures that the mesh of

《时间的痕迹,ensures网大学

each gear is correc t, before the timing of the fuel

每个锥齿轮修正之前的时间t的燃料

injection pump is checked and before the tappet

注射泵和冰检查之前的挺杆

clearances are set. The teeth of the timing gears are

间隙是看到的。《定时齿轮的齿。

engaged correctly when the mark on the side of the

这样定下来correctly当马克在一边的

tooth of a gear is between the marks on the s ides of

锥齿轮的齿之间的马克在大学的理念

two teeth of another gear (A).

另一个齿轮两齿部(A)。

Timing gears and auxiliary drive shaft

正时齿轮和辅助传动轴

To obtain access to the timing gears, the engine must

要获得定时齿轮,Perkins3012发动机必须

be disengaged from its driv en unit and its radiator,

从其驱动装置及其散热器脱离,

and fitted in a build stand if it is av ailable, operation

安装在构建是否有效站,操作

16-1.

16-1。

This operation includes the removal of the fan, the air

此操作包括风扇的拆卸,空气

cleaners and the support brackets, the air ducts, the

吸尘器及支架、风道、

coolant pipes and, if the engine is to be fitted in a build

冷却液管,如果Perkins3012发动机是在建造中安装的

stand, the front covers of the coolant galleries.

站,冷却液展览馆的前盖。

If a build stand is not av ailable, put the engine on

如果一个站没有建立有效,把Perkins3012发动机

wooden supports on a strong hard floor and put a

在坚硬的地板上的木板支撑着

secure support under the rear of the sump adaptor in

在贮水池适配器的后部的安全支架

order to hold the flywheel housing above the floor.

为了将飞轮壳上方的地板上。

1 Remove the starter motor, if the engine has not

1拆下起动电机,如果Perkins3012发动机没有

been fitted in a build stand.

已安装在一个建立的立场。

2 Open the cover on the flywheel housing and

2打开飞轮壳盖

remove the timing pointer.

删除定时指针。

3 Remove the flywheel, operation 22-1.

3拆卸飞轮,操作22-1。

4 Disconnect the fuel pipes from the fuel lift pump and

4断开燃油泵和燃油管的连接

the connection block for the spill fuel.

泄漏燃料的连接块。

5 Remove the guard of the aux iliary drive.

5拆下的辅助驱动保护。

6 Disconnect the delivery pipe for the lubricating oil

6断开润滑油的输送管

between the crankcase and the housing of the fuel lift

在曲轴箱和燃油箱的壳体之间

pump.

泵。

7 Remove the assembly of the mounting for the fuel

7拆下安装的燃料组件

lift pump and release the nut which retains the cam on

提起泵,松开保持凸轮的螺母

the auxiliary drive shaft. Withdraw the spring washer

辅助传动轴。撤回弹簧垫圈

and the cam, and ensure that the ’Woodruff’ key is not

与凸轮,并确保'半圆键不

lost.

失去了。

8 Disconnect and remove the fuel injection pump,

8断开并拆下喷油泵,

operation 20-11.

操作20-11。

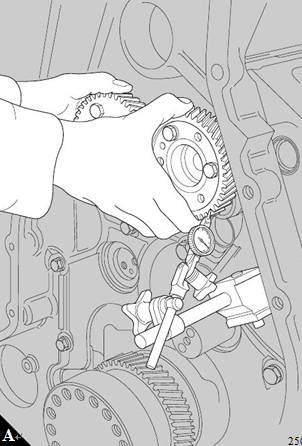

9 From the inner end of the auxiliary drive shaft (A),

9从辅助驱动轴的内端(一),

release the nut that retains the flange of the coupling.

松开保持连接的法兰的螺母。

Remove the plain washer. Use the puller, 21825 837,

清除普通垫圈。用拉具,21825 837,

with the two bolts, 21825 839, to withdraw the flange.

用两根螺栓,839 21825,取下凸缘。

Remove the Woodruff key. Before the engine is

拆下半圆键。在Perkins3012发动机前

dismantled further, check the backlash of the auxiliary

进一步拆除,检查辅助的反弹

drive gear, if relevant to the job, as follows.

传动齿轮,如果与工作相关的话,如下。

10 Put the special tool, VT15279, on the drive shaft

10将专用工具,vt15279,在传动轴

and retain it with the nut from the coupling flange. Put

并将其与法兰连接的法兰连接。把

a dial test indicator with a magnetic base in the ’V’ of

在“五”的“伏”的磁性基地的拨号测试指标

the crankcase. Set the button of the dial test indicator

曲轴箱。设置拨号测试指示器的按钮

on one of the faces of the special tool which is used

在使用的专用工具的一个面上

as a datum. Turn the s pecial tool to the limit of its

作为基准。把特殊的工具,它的极限

movement in both directions and check the reading

在两个方向的运动,并检查阅读

on the dial test indicator. The permissible backlash is

在拨号测试指示器。允许的间隙是

0,10 to 0,33 mm (0.004 to 0.013 in). Remove the

不同于0,33毫米(0.004到0.013)。拆下

special tool.

专用工具。

11 Release the four bolts for early engines (six bolts

11释放早期Perkins3012发动机的四个螺栓(六个螺栓

for new engines) which retain the housing for the oil

用于新Perkins3012发动机),它保留了机油的外壳

seal. Remove the housing and keep the pack of

密封。拆除房屋并保持包装

laminated shims.

复合垫片。

12 Remove the flywheel housing, operation 22-4.

12拆下飞轮壳,操作中可以看到。

13 Withdraw the assembly of the auxiliary drive shaft

13撤回辅助传动轴的装配

from the timing case, and remove and discard the oil

从定时的情况下,取出并丢弃油

seal of the drive shaft. Current engines have

传动轴密封。目前的Perkins3012发动机

improved oil seals which are integral with their

改进的油封,这是与他们的

housings and for these engines the housing must be

壳体和用于这些Perkins3012发动机的壳体必须是

discarded.

丢弃。

During the operation to remove the timing gears,

在操作过程中,以除去定时齿轮,

check the backlash of each gear. Use generally the

检查各齿轮的齿隙。使用一般的

method whic h is given for the assembly of the gears.

方法,它给出了齿轮的装配。

Make a record of the results.

记录下结果。

To check the backlash of the camshaft gears, the

要检查凸轮轴齿轮的齿隙

rocker boxes or pedestal rocker assemblies must be

必须是摇杆箱或底座摇杆组件

removed, operation 12-5, or operation 12-2, to

删除操作12-5,或操作12-2,以

release the pressure of the valve springs.

释放气门弹簧的压力。

14 Turn backward one or two turns the nut which

14把后一个或两个圈转一圈

retains the gear of the coolant pump. Remove the

保留冷却液泵的齿轮。拆下

four nuts and the spring washers from the s tuds which

四螺母和弹簧垫圈的tuds这

retain the coolant pump and lift away the coolant

保留冷却液泵,并将冷却液带走

pump from the timing case.

定时的泵。

15 Remove the nut which retains the gear and use

15拆下保留齿轮和使用的螺母

the puller, 21825 837, with the two bolts, 21825 839,

车夫,21825 837,用两个螺栓、21825 839,

to withdraw the gear from the shaft of the coolant

从冷却液的轴上取齿轮

pump.

泵。

16 Release and remove the bolt and the spring

16松开并拆下螺栓和弹簧

washer from the axle of the idler gear for the coolant

从惰齿轮轴垫圈的冷却剂

pump. Lift away the assembly of the gear and the

泵。抬起齿轮和齿轮的装配

axle.

轴。

17 Fit two 16 mm bolts, whic h are similar to the bolts

17安装两个16毫米螺栓,它类似于螺栓

which retain the fly wheel, in the face at the rear end of

其中保留的飞轮,在面对在后端

the crankshaft. These bolts should be used only to

曲轴。这些螺栓只能用在

turn the crankshaft with a suitable lever.

用一个合适的杠杆将曲轴转动。

18 Turn the crankshaft until each location dowel of

18转动曲轴,直到每个定位销钉

the camshaft gears is toward the centre of the engine.

凸轮轴齿轮正朝向Perkins3012发动机的中心。

Remove the bolts which retain the camshaft gears

拆下保留凸轮轴齿轮的螺栓

and us e levers to remove c arefully the drive gear of

和我们E杠杆删除C全传动齿轮

the fuel injection pump/camshafts and the two

喷油泵凸轮轴和两/

camshaft gears from the ends of the camshafts.

凸轮轴齿轮与凸轮轴的两端。

19 Bend backward the tabs of the lock plate of the

19弯曲向后的锁板的标签

bolts which retain the assembly of the ax le for the

保留了斧头的装配的螺栓

main idler gear. Release the bolts and remove the

主传动齿轮。松开螺栓并拆下

assembly of the axle and the gear wheel.

车轴和齿轮的装配。

20 Similarly, remove the double idler gear with the

20同样,以消除双惰轮

assembly of its axle.

车轴总成。

To fit

适合

Check that the flanges at the drive ends of the

检查在驱动端部的法兰

camshafts are clean and are not damaged. Turn the

凸轮轴是清洁和不受损坏。转

crankshaft until the A6 piston is at TDC and fit the

活塞在曲轴直到A6 TDC和适应

assembly of the double idler gear as follows:

对双惰轮组件如下:

1 Slide the inner thrust washer, the assembly of the

1滑动内止推垫片,装配

gear, and the outer thrust washer onto the assembly

齿轮,和外部的推力垫圈装配

of the distance piece and the axle. Hold the

的距离和轴。持有

components in their positions on the distance piece.

组件在它们的位置上的距离。

Fit the assembly of the axle and the distance piece

安装轴和距离件的装配

through the timing case and into its recess in the end

通过定时的情况下,进入它的休会结束

face of the crankcase.

曲轴箱的面。

Ensure that the inner thrust was her remains in its

确保内在的推力是她的遗体

position on the distance piece. It is not possible to fit

距离件上的位置。这是不可能的

the double idler gear onto the axle when the axle is

双齿轮在轴上的轴时

fitted already into its recess.

已安装在其凹部中。

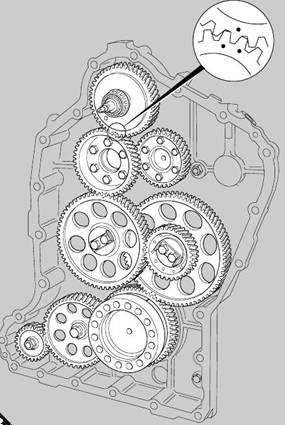

Ensure that the mesh is correct of the two timing

确保网格的正确性

marks on the teeth of the large gear with the single

大齿轮的齿痕与单

timing mark on the crankshaft (A).

曲轴上的正时记号(一)。

2 Hold the thrust plate and the lock plate against the

2持有推力盘和锁定板

end of the axle and fit the two bolts. Tighten lightly the

轴的一端和配合的螺栓。轻轻拧紧

two bolts.

两个螺栓。

3 Put a dial test indicator with a magnetic base in a

3在一个磁性底座上放置一个拨号测试指示器

suitable position and set the button on one of the teeth

合适的位置,并设置一个按钮上的牙齿

of the larger gear of the double idler gear. Check the

对双辊齿轮大齿轮。检查

reading for the backlash of the larger gear which is

对于较大齿轮的齿隙读数

relevant to the gear of the crankshaft. The permissible

与曲轴齿轮相关。允许

backlash is 0,100 to 0,240 mm (0.004 to 0.009 in).

间隙为0100至0240毫米(0.004至0.009英寸)。

Caution: To prevent axial movement when the

警告:防止轴向运动时

backlash is checked, press each idler gear against its

间隙检查,按每个齿轮与

inner thrust washer.

内止推垫圈。

4 Move the dial tes t indicator to another suitable

4将拨到另一个合适的测试指标

position and set the button on the front face of the

位置并设置按钮在前面的脸上

smaller gear. Check the axial movement of the

小齿轮。检查轴向运动

assembly of the double idler gear. The permissible

的双齿轮组件。允许

end-float is 0,100 to 0,425 mm (0.004 to 0.017 in).

最终的浮动是0100至0425毫米(0.004至0.017英寸)。

5 Tighten to 135 Nm (100 lbf ft) the two bolts and

5拧紧135牛米(100磅英尺)的两个螺栓和

bend up each end of the lock plate.

把锁板的两端弯折。

Assemble and fit the main idler gear as follows:

装配、安装主传动齿轮如下:

6 Insert the assembly of the axle through the timing

6通过定时插入轴的装配

case and into its recess in the end face of the

在结束的情况下,进入它的休息的脸

crankcase. Fit the inner thrust washer and the gear.

曲轴箱。安装内止推垫圈和齿轮。

Ensure that the mesh is correct of the timing mark on

确保网格是正确的时间标记

the tooth of the main idler gear with the two timing

与两个定时的主要中间齿轮齿

marks on the teeth of the smaller gear of the double

双齿小齿轮的齿痕

idler gear. Fit the outer thrust washer, the thrust plate,

惰轮。安装外部推力垫圈,推力板,

the lock plate and the two bolts which retain the

锁盘和两根螺栓,保留

assembly. Tighten lightly the two bolts.

装配。轻轻拧紧两根螺栓。

7 Put the dial test indicator in a suitable position and

7将拨测指标放在适当的位置

set the button on one of the teeth of the main idler

设置按钮在一个主要的托牙

gear. Hold stationary the double idler gear and check

齿轮。保持固定的双齿轮和检查

the reading for the backlas h of the main idler gear.

的主要中间齿轮的backlas阅读H。

The permissible limits are 0,100 to 0,270 mm (0.004

允许的限制是0100至0270毫米(0.004

to 0.011 in).

到0.011。

8 Move the dial tes t indicator to another suitable

8将拨到另一个合适的测试指标

position and check the axial movement of the

位置和检查的轴向运动

assembly of the main idler gear. The permissible

的主要中间齿轮总成。允许

end-float is 0,100 to 0,425 mm (0.004 to 0.017 in).

最终的浮动是0100至0425毫米(0.004至0.017英寸)。

Tighten the two bolts to 135 Nm (100 lbf ft).

拧紧螺栓的两个135牛米(100磅英尺)。

9 Fit the idler gear for the coolant pump onto the

9安装惰轮的冷却液泵上

assembly of its axle, followed by the thrust washer. Fit

其轴的装配,其次是推力垫圈。适合

the ass embly of the axle in its location in the end face

驴集合在端面的定位轴

of the crankcase and retain with the bolt and its spring

在曲轴箱和保持螺栓和弹簧

washer. Tighten lightly the bolt.

洗衣机。拧紧螺栓。

10 Put the dial test indicator in a suitable position and

10将拨测指标放在适当的位置

set the button on one of the teeth of the idler gear of

设置按钮的一对齿轮的齿

the coolant pump. Check the reading for the backlash

冷却液泵。检查读数的间隙

of the idler gear that is relevant to the gear of the

的齿轮,在齿轮的相关

crankshaft. The permissible backlash is 0,100 to

曲轴。允许间隙为0100

0,240 mm (0.004 to 0.009 in).

0240毫米(0.004至0.009英寸)。

11 Move the dial test indicator to another suitable

11将拨测指标移动到另一个合适的

position and check the axial movement of the idler

位置和检查托辊的轴向移动

gear of the coolant pump. The permissible end-float

冷却液泵齿轮。允许的最终浮动

is 0,20 to 0,40 mm (0.008 to 0.016 in). Tighten to 135

是20到1,00毫米(0.008到0.016)。拧紧135

Nm (99.6 lbf ft) the bolt which retains the assembly.

nm(99.6磅英尺)螺栓保留装配。

12 Check that the flange of the coolant pump and its

12检查冷却液泵的法兰及其

mounting on the timing case are clean. Put a new

安装在计时的情况下是干净的。把一个新的

joint over the studs and fit the assembly of the coolant

接头在螺柱上,配合冷却液的装配

pump to the timing case with four nuts and four spring

泵到定时的情况下有四个螺母和四个弹簧

washers.

垫圈。

Caution: On the industrial engines, the outlet of the

警告:在工业Perkins3012发动机上,出口的

pump is downward.

向下泵。

13 Put the dial test indicator in a suitable position and

13将拨测指标放在适当的位置

set the button on one of the teeth of the drive gear of

设置一个齿轮的齿的按钮

the coolant pump. Hold stationary the idler gear and

冷却液泵。保持固定的齿轮和

check the backlash of the drive gear of the coolant

检查冷却液驱动齿轮的齿隙

pump. The permissible backlash is 0,100 to 0,280

泵。允许间隙为0100至0280

mm (0.004 to 0.011 in).

毫米(0.004至0.011英寸)。

14 Fit the gear of ’A’ bank on the flange of its

14将“一”银行的齿轮安装在其法兰上

camshaft, insert the dowel and retain the gear with

凸轮轴,插入销钉和保留的齿轮

three temporary bolts.

三个临时螺栓。

15 Insert the timing mark on one tooth of the gear of

15在齿轮的一个齿上插入时标

’B’ bank between the two timing marks on the teeth of

'乙'银行之间的2个时间标记的牙齿上

the gear of ’A’ bank and fit the gear of ’B’ bank on the

'银行'的齿轮,配合'乙'银行的齿轮

flange of its camshaft. Insert the dowel and retain the

凸轮轴的凸缘。插入销钉和保留

gear with three temporary bolts. To check the

带三个临时螺栓的齿轮。检查

backlash of the camshaft gears, the rocker boxes, or

凸轮轴齿轮,摇臂箱,或

the pedestal rocker assemblies, must be removed

必须拆除的底座摇杆组件

(operation 12-5 or operation 12-2) to release the

(操作12-5或操作12-2)释放

pressure of the valve springs.

阀门弹簧的压力。

Check the backlash of the gears of the camshafts as

检查凸轮轴的齿轮侧隙为

follows:

如下:

16 Put a dial test indicator with a magnetic base in the

16将一个拨号测试指标与磁性基础

timing case and set the button on the side of a tooth

定时的情况下,并设置按钮的一侧上的牙齿

of the camshaft gear of ’A’ bank (A). Hold stationary

'一'银行的凸轮轴齿轮(一)。保持平稳

the camshaft gear of ’B’ bank and rotate the camshaft

'乙'银行的凸轮轴齿轮和转动凸轮轴

gear of ’A’ bank to the limit of its movement in both

'一'银行的齿轮的限制,其运动的两个

directions. Check the reading on the dial test

方向。检查刻度盘上的读数

indicator. Permissible backlash for the camshaft

指示器。凸轮轴的允许间隙

gears is 0,100 to 0,250 mm (0.004 to 0.010 in).

齿轮为0100至0250毫米(0.004至0.010英寸)。

Caution: To ensure that a correct reading is

警告:确保正确的阅读是

obtained, it is important that the gear of ’B’ bank is not

得到的,它是重要的,'乙'银行的齿轮是不

allowed to move during this operation.

允许在该操作期间移动。

17 Remove the three temporary bolts from the

17拆下三个临时螺栓

camshaft gear of ’A’ bank only. Apply ’Loctite 542’

'银行'的凸轮轴齿轮。申请“Loctite 542

hydraulic sealant to the threads of the six bolts which

液压密封件的六个螺栓的螺纹

retain the camshaft gear and fit the bolts, together

保留凸轮轴齿轮并配合螺栓,在一起

with plain washers, through the camshaft gear.

用平垫圈,通过凸轮轴齿轮。

Tighten each bolt to 40 Nm (30 lbf ft).

拧紧每个螺栓40牛米(30磅英尺)。

Remove the three temporary bolts from the cams haft

取下凸轮轴三临时螺栓

gear of ’B’ bank and proceed:

'乙'银行的齿轮并进行:

18 Ensure that the two dowels which provide the

18确保两销提供

locations for the camshaft gears are toward the centre

凸轮轴齿轮的位置向中心

line of the engine. Fit the drive gear of the fuel

Perkins3012发动机生产线。安装燃油的驱动齿轮

injection pump/camshafts onto the extension of the

喷油泵凸轮轴上的延伸/

dowel of the ’B’ bank camshaft gear. Ensure that the

B银行的凸轮轴齿轮定位。确保

gears mesh c orrectly: the two timing marks of the

C正确:齿轮啮合的两时标

drive gear for the fuel injection pump/ camshafts with

对喷油泵、凸轮轴驱动齿轮

the timing mark on the main idler gear (B). The two

在主传动齿轮的正时标记(B)。两

timing marks on the drive gear of the fuel injection

喷油器驱动齿轮上的计时标记

pump/camshafts is then in the correct position to

然后泵/凸轮轴是在正确的位置

receive the timing mark of the auxiliary drive gear.

接收辅助传动齿轮的定时标志。

Retain the drive gear of the fuel injection pump/

保留燃油喷射泵的驱动齿轮

camshafts with three temporary bolts.

三临时螺栓凸轮轴。

Two extra sets of two timing marks are

双套双计时标志

provided, on the drive gear of the fuel injection pump/

提供燃油喷射泵的驱动装置/

camshafts, for the correct timing of two compressors

凸轮轴,对两压缩机的正确时机

in the automotive applications only (A). Ensure that

在汽车应用中(一)。确保

the correct timing marks are aligned during the

在正确的时间标记是对齐的

assembly of the timing gears.

正时齿轮组件。

19 Put the dial test indicator in a suitable position and

19将拨测指标放在适当的位置

set the button on one of the teeth of the drive gear of

设置一个齿轮的齿的按钮

the fuel injection pump/ camshafts. Hold the main

喷油泵凸轮轴/。持有为主

idler gear and check the reading for the bac klash of

惰轮检查BAC的侧间隙的阅读

the drive gear of the fuel injection pump/camshafts.

喷油泵的凸轮轴驱动齿轮/。

The permissible limits are 0,100 to 0,270 mm (0.004

允许的限制是0100至0270毫米(0.004

to 0.011 in).

到0.011。

20 Remove the three temporary bolts from the drive

20从驱动器上拆下三个临时螺栓

gear of the fuel injection pump/camshafts. Apply

喷油泵的凸轮轴齿轮/。应用

’Loctite 241’ to the threads of the six bolts which retain

“乐泰241”到六,保留螺纹螺栓

the drive gear and fit the bolts, with the plain washers,

传动齿轮,配合螺栓,用平垫圈,

in the drive gear. Tighten each bolt to 70 Nm (52 lbf

在传动齿轮。拧紧每个螺栓70 nm(52磅

ft).

英尺)。

21 If relevant, fit the rocker boxes or pedestal rocker

21如果相关的话,适合的摇杆框或底座摇杆

assemblies, operation 12-5 or operation 12-2.

组件、操作或操作12-2 12-5。

Assemble the auxiliary drive shaft as follows:

装配辅助传动轴:

22 Fit the assembly of the auxiliary drive s haft in the

22适合的辅助传动轴装配在

outer race of the inner roller bearing. The mesh of the

内辊轴承外圈。网格的

timing mark on the gear with the two timing marks on

时间标记在齿轮上的2个计时标记

the drive gear of the fuel injection pump must be

喷油泵的驱动装置必须是

correct (A).

正确(一)。

23 Fit the flywheel housing, operation 22-4.

23安装飞轮壳22.4,操作。

24 Fit the housing for the oil seal of the auxiliary drive

24配合房屋的油封的辅助传动

shaft, with a complete pack of laminated shims, onto

轴,一个完整的包的夹层垫片,上

the shaft and retain them with four bolts for early

竖井,并用四颗螺栓固定住他们的早期

engines, or six bolts for new engines, to the timing

Perkins3012发动机,或六个新的Perkins3012发动机螺栓,以时间

case. Do not press in a new oil seal, if relevant, or the

案例。如果有相关的话,不要压在新的油密封件上

Woodruff key of the drive shaft, during this operation.

半圆键的驱动轴,在该操作中。

25 Fit the special tool, VT15279, to the auxiliary drive

25安装专用工具,vt15279,来辅助驱动

shaft and retain it with the nut from the c oupling

轴和保留它从耦合螺母

flange. Put a dial test indicator with a magnetic base

法兰。带磁性底座的拨号测试指示器

in the ’V’ of the crankc ase. Set the button of the dial

在“V”的crankc ASE。设置拨号按钮

test indicator on one of the faces of the special tool

专用工具的一个面上的测试指示器

which is used as a datum. Turn the special tool to the

作为基准使用。把专用工具变成

limit of its movement in both directions and check the

其在两个方向的运动的限制,并检查

reading on the dial test indicator. The permissible

在拨号测试指示器上读取。允许

backlash is 0,10 to 0,33 mm (0.004 to 0.013 in).

反弹是0到0,33毫米(0.004到0.013)。

Remove the special tool.

取出专用工具。

26 Move the dial test indicator to another suitable

26将拨测指标移动到另一个合适的

position and check the axial movement of the

位置和检查的轴向运动

assembly of the auxiliary drive. The permissible end-

辅助传动装置。容许端—

float is 0,076 to 0,127 mm (0.003 to 0.005 in). To

浮动为0076至0127毫米(0.003至0.005)。以

adjust the end-float, remove the housing of the oil seal

调整底浮,拆下机油密封壳

and reduce the thickness of the pack of the laminated

并减少了叠层的厚度

shims. Tighten the bolts which retain the housing of

垫片。拧紧保持房屋的螺栓

the oil seal.

油密封。

27 Chec k that the taper of the auxiliary drive shaft is

27测查,辅助传动轴的锥度

clean, press in a new oil seal if relevant, and press the

清洗后,按新的机油密封,并按

Woodruff key into its keyway. Fit the flange for the

半圆键在键槽。安装法兰为

drive coupling onto the shaft, followed by the plain

驱动耦合到轴,然后由平原

washer and the nut. Tighten the nut to the relevant

垫圈和螺母。拧紧螺母到相关的

torque loads:

转矩负载:

18 mm nut 200 Nm (148 lbf ft).

18毫米螺母200 nm(148磅英尺)。

22 mm nut 300 Nm (220 lbf ft).

22毫米螺母300 nm(220磅英尺)。

28 Fit the fuel injection pump, operation 20-11.

28安装喷油泵,操作20-11。

29 Press the ’Woodruff’ key for the cam into its

29按“半圆键为凸轮的

location in the outer end of the auxiliary drive shaft.

辅助驱动轴的外端位置。

Slide the cam which drives the lift pump onto the drive

将举升泵驱动的凸轮滑动到驱动器上

shaft, followed by the spring washer and the nut.

轴,然后由弹簧垫圈和螺母。

Tighten the nut to 54 Nm (40 lbf ft).

拧紧螺母54牛米(40磅英尺)。

30 Fit the assembly of the mounting for the fuel lift

30安装燃油升降机的安装组件

pump, operation 20-4.

泵运行20-4。

31 Connect the delivery pipe for the lubricating oil

31连接润滑油的输送管

between the crankcase and the fuel lift pump.

在曲轴箱和燃油泵之间。

32 Fit the guard of the auxiliary drive.

32配合辅助传动的防护。

33 Connect the fuel pipes from the fuel lift pump and

33连接燃油泵和燃油管的连接

the connection block for the spill fuel.

泄漏燃料的连接块。

34 Fit the flywheel, operation 22-1.

34安装飞轮,操作22-1。

35 Remove the engine from the build stand,

35从建造支架上拆下Perkins3012发动机,

operation 16-1.

操作16-1。

1 Wash all the gears in kerosene, remove all the

1用煤油清洗所有的齿轮,除去所有的

deposits of thread locking compound and inspect the

螺纹锁紧复合物的沉积

teeth for wear.

磨损牙。

Wear on the teeth is acceptable if there is no sign of

如果没有任何迹象,牙齿上的磨损是可以接受的

erosion, and if the backlash is within the permissible

腐蚀,如果间隙是允许的

To dismantle and to assemble

拆卸和组装

To dismantle

拆除

15-4

15-4

limits.

限制。

2 Test all the gears for cracks. Use the

2测试所有的齿轮裂纹。使用

electromagnetic method, if it is possible.

如果可能的话,电磁法。

3 Check the bus hes and the axles of the idler gears

3检查总线他和惰齿轮轴

for wear. If suitable workshop facilities are available,

磨损。如果合适的车间设施,

new bushes may be fitted to the idler gears. New

灌木可以安装在从动齿轮。新的

bushes are pre-finished and no further processes are

灌木是预先完成,没有进一步的过程是

necessary after they have been fitted.

必要后,他们已经安装。

4 Inspect the thrust washers. The thrust washers

4检查推力垫圈。止推垫圈

must be renewed if there is a reduction in the size of

如果有减少的尺寸,必须重新更换

the grooves in the thrust faces.

推力面上的凹槽。

5 If it is necess ary to inspect the gears of the

5如果它是必要的检查的齿轮

lubricating oil pump, for early engines, the

早期Perkins3012发动机的润滑油泵

lubricating oil sump and the sump adaptor must be

润滑油底壳和油底壳接头必须是

removed, operation 19-1 and operation 19-3

删除操作19-1经营19-3

respec tively. For new engines, the single piece

分别。对于新引擎,单块

sump must be removed, operation 19-5.

水池必须移除操作19-5。

Double idler gear

双惰轮

1 For early engines, remove the six bolts which retain

1为早期Perkins3012发动机,拆下六个螺栓,保留

the auxiliary drive gear and withdraw the gear from

辅助传动装置和从

the spigot of the auxiliary drive shaft.

该辅助传动轴承。

To assemble

组装

2 For early engines, put the gear on the spigot of the

2早期的引擎,把齿轮上的插口

shaft and, if necessary, fit the locating dowel.

轴和,如果有必要,将定位销。

3 Apply ’Loctite 241’ to the threads of the six bolts

3适用的Loctite 241 '的六个螺栓的螺纹

which retain the gear and insert the bolts, with plain

其中保留齿轮和插入螺栓,与平原

washers, in the bolt holes of the gear.

齿轮的螺栓孔的垫圈。

4 Tighten evenly the bolts to a torque of 40 Nm (30

4将螺栓拧紧至40纳米(30

lbf ft).

磅英尺)。

To dismantle and to assemble

拆卸和组装

To dismantle

拆除

1 Release the 12 bolts from the large gear and

1从大齿轮上松开12个螺栓

separate the two gears.

单独的齿轮。

To assemble

组装

If the bush of the gear needs to be renewed, it may be

如果齿轮的衬套需要更换,则可能

an adv antage to do this while the two gears are

一个优势为此而两齿轮

separated, operation 15-2.

分离,操作15-2。

1 Ensure that the two gears are clean and dry.

1确保齿轮的清洁和干燥。

Fit in its correct position the larger gear on the spigot

安装在正确的位置上的插口较大的齿轮

of the small gear, and insert the dowel.

在小齿轮,并插入销。

2 Apply ’Loctite 241’ to the threads of the 12 bolts

2适用的Loctite 241 '的12个螺栓的螺纹

which hold together the assembly, and insert the

其中一组在一起,并插入

bolts, with plain washers, into the bolt holes.

螺栓,用平垫圈,入螺栓孔。

3 Tighten each bolt to a torque of 40 Nm (30 lbf ft).

3拧紧每个螺栓的扭矩40牛米(30磅英尺)。

Note: The grade of bolts which retain the timing case

注意:螺栓的等级,保留时间的情况

(A1) on the crankcase was changed in 1994. If the

(A1)曲轴箱上的转变在1994。如果

timing case is removed from an engine with a build

定时的情况下,从Perkins3012发动机上拆下的一个引擎

line number before 12103, the bolts should be

12103号线前,螺栓应为

renewed and the latest steel joint must be fitted. The

必须安装最新的钢接头。这个

new bolts should be tightened to a torque of 135 Nm

新的螺栓应拧紧至135纳米的扭矩

(99.5 lbf ft). The five bolts which fit into the sump

(99.5磅英尺)。装在水池中的五个螺栓

should be tightened to 75 Nm (55 lbf ft).

应拧紧75 nm(55磅英尺)。

To remove

删除

1 Remov e the timing gears and the auxiliary drive

1清除定时齿轮和辅助驱动

shaft, operation 15-1.

轴,操作15-1。

2 From the bolts which retain the timing case, remove

2从螺栓上保留时间的情况下,取出

two bolts from the horizontally opposite sides of the

两根螺栓从横向相对的两侧

timing case. Make locally two guide studs and fit

正时箱。做本地双导轨螺栓和配合

them into the bolt holes.

他们进入螺栓孔。

3 Us e a hoist and a rope sling through the opening for

3我们是一个提升机,一个是用绳子吊着的

the auxiliary drive shaft (A2) to hold the timing case,

辅助传动轴(A2)举办时间情况,

and remove the remainder of the bolts and the single

除去剩下的螺栓和单

nut on early engines. Release carefully the timing

早期Perkins3012发动机上的螺母。小心地释放时间

case from its dowels and lift it away from the

从其销案例举离

crankcase.

曲轴箱。

To fit

适合

Caution: For new engines which have the steel joint,

警告:新Perkins3012发动机的钢接头,

CV14584, the bolts which fasten the timing case to

cv14584,螺栓紧固定时案例

the crankcase and the sump are of a higher tensile

曲轴箱和油底壳具有较高的拉伸强度

strength, and an additional bolt is fitted instead of the

强度,和一个额外的螺栓安装,而不是

stud. Also, the large dowel is retained by cap screws

螺柱。同时,大柱是由螺丝帽保留

instead of bolts.

代替螺栓。

1 Make locally a minimum of six suitable guide studs.

1在当地至少有六个合适的引导钉。

Degrease thoroughly the joint faces of the crankcase,

充分脱脂的曲轴箱接合面,

the timing case and the end of the sump, or the sump

时间的情况下,底壳,或污水坑

adaptor as relevant, if it has not been removed. Fit

适配器相关的,如果它没有被删除。适合

the guide studs into the bolt holes in the crankcase.

在曲轴箱中的螺栓孔中的导向螺栓。

2 Apply a 5 mm bead of silicone sealant, ’Hylosil

2采用5毫米珠硅酮密封胶,“hylosil

RTV’, across the full width of each face where the joint

RTV,全宽面连接处

between the sump (or sump adaptor) and the

之间的油底壳(或油底壳适配器)和

crankcase can be seen. Fit carefully a new joint onto

可以看到曲轴箱。小心一个新的连接到

the guide studs and move it against the joint face.

引导螺柱,并将其移向接合面。

Ensure that there is no distortion at the lower end of

确保在较低的一端没有失真

the joint.

联合。

Note: Early engines were fitted with a fibre joint; the

注:早期Perkins3012发动机配有光纤接头;

new joint is made from steel and has a lay er of sealant

新接头是由钢制成的,有一个密封的密封胶条

already applied.

已经应用。

3 Use the rope sling through the opening for the

3使用绳套,通过开

auxiliary drive shaft (A2) to fit carefully the timing case

辅助驱动轴(A2)适合仔细定时情况

onto the guide studs. Release the rope sling and slide

在导向螺栓上。松开钢丝绳和滑动

the timing case up to the crankcase.

定时的情况下,到曲轴箱。

400-100-8969 15088860848

0574-26871589 15267810868

0574-26886646 15706865167

0574-26871569 18658287286

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文(简)

中文(简) Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska