帕金斯柴油发动机交流充电发电机维修技术资料

帕金斯柴油发动机交流充电发电机维修技术资料

Alternator

交流发电机

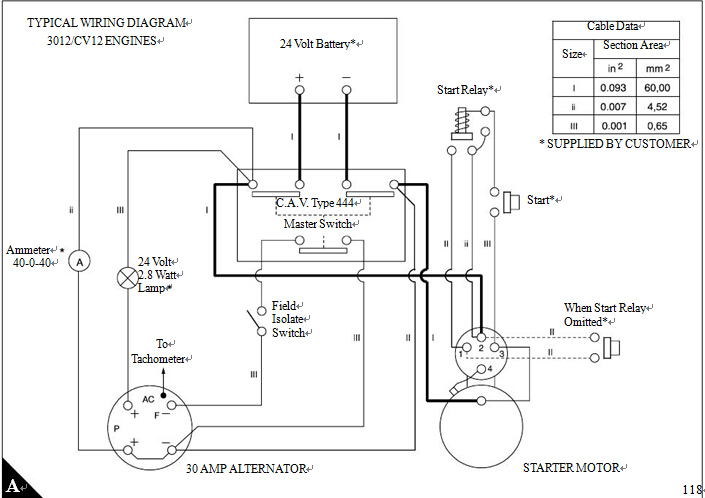

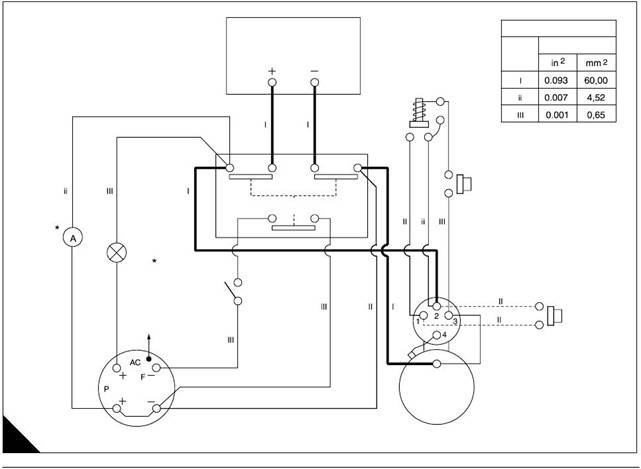

The three phase (star connected) alternator is of the

三相(星形连接)交流发电机的

rotating field and stationary armature (stator) type (A).

旋转磁场和固定电枢(定子)类型(一)。

The rectifier consists of six silicon diodes. These are

整流器由六个硅二极管组成。这些都是

retained by the two heat sinks in the assembly of the

由两个散热片保留在组装

rectifier, which is in the housing at the slip ring end.

整流器,这是在外壳的滑动环结束。

Excitation of the field is done by three auxiliary diodes

励磁的领域是由三个辅助二极管

which are assembled in the centre of the rectifier.

这是在整流器中心组装。

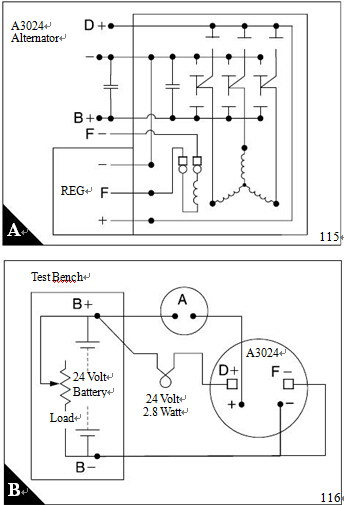

The output is controlled by an integral regulator and

输出是由一个积分调节器和控制

the maximum rated output (hot) is 32 amps at 28

最大额定输出(热)是32安培在28

volts. A diagram of connections for a suitable

伏。一个合适的连接图

dynamic test rig is shown (B).

动态试验台(乙)。

Starter motor

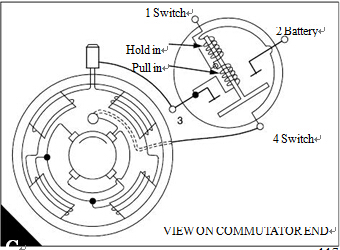

The heavy-duty starter motor is flange mounted and

is operated by a 24 volt electrical supply. A solenoid

type of start switch is fitted on the outside of the

starter motor (C). The plunger of the switch also

actuates, by the use of a screw link and a shift lever,

the assemblies of the armature and the pinion. The

assembly of the pinion includes a device to ensure its

engagement, a clutc h to ensure that the motor is not

overloaded, and a device for free rotation in one

Operation of the start button energises two windings

around the plunger of the solenoid. One winding pulls

the plunger which causes the shift lever to move the

pinion of the starter motor into mesh with the s tarter

ring. The other winding holds the plunger to ensure

that the pinion remains in mesh. If the teeth of the

pinion do not engage immediately, the pinion moves

backward against its spring and there is a small

amount of rotation until the engagement occurs. The

start switch operates when the pinion is engaged.

The electrical current then flows directly from the

battery to the starter motor. This circuit is parallel to

the circuit through the winding which pulls the

plunger, and the flow of current through the winding is

stopped. The winding which holds the plunger

continues to be energised until the start button is

A device for free rotation in one direction is included

A device for free rotation in one direction is included

in the assembly of the pinion to prevent damage to the

armature, the teeth of the pinion and the teeth of the

starter ring when the engine starts. When the start

button is released, a spring withdraws the pinion

along the splined shaft of the armature to its original

position.

Warning/engine stop switches

Two switches are included in the cooling system and

the lubrication sy stem. They give protection to the

engine if the coolant temperature or the oil pressure

exceed the permissible limits. Certain engines have

an extra switch whic h gives protection to the engine if

the coolant level is below a certain limit.

The switches operate, according to the circuits for

specific applications, if there is an increase in the

temperature of the coolant or if there is a decrease in

the pressure of the engine lubricating oil.

The switches are set at the factory to operate within a

selected range of temperatures and pres sures. Do

not try to alter the settings. No maintenance is

necessary for the switches except to check at

intervals for their correct operation.

Stop solenoid

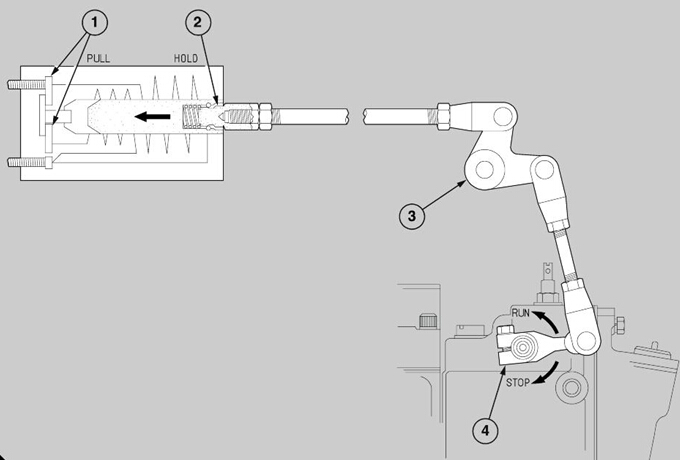

The stop solenoid, which is generally for an ’energise

to run’ system, is fitted on the inner wall of the

induction manifold of ’A’ bank. The stop solenoid is

connected by a spherical coupling (A2), through a bell

crank lever (A3) and linkage, to the stop control lever

(A4) on the governor.

When the stop solenoid is energised, the two circuits

in the windings of the solenoid actuate a plunger

which moves the lever of the stop control to the ’RUN’

position. One winding pulls the plunger in the

direction of the arrow until the internal switch contacts

(A1) are separated. The circuit through the winding is

then broken but the other winding remains energised,

with low consumption, to hold the plunger and keep

the lever for the stop control in the ’RUN’ position.

When the winding is de-energised, a spring returns

the plunger to its normal position and the lever of the

stop control to the ’STOP’ position. This oc curs when

the ’STOP’ button is pressed, when an engine

protection device breaks the circuit, or when there is

an electrical failure.

The system needs an accurate adjustment of the

linkage between the stop solenoid and the lever of the

stop control. An incorrect adjustment can c ause

damage to the fuel injection pump, or may burn the

windings which pull the plunger.

Alternator

To remove and to fit

It is not advisable to attempt repairs to the alternator.

This work requires specialist equipment and

knowledge. If alternator failure occurs, operators are

advised to take advantage of the Perkins service

exchange scheme.

To remove

1 Disconnect the battery.

A

59

2 For engines which are remotely cooled, remove the

alternator guard.

3 Disconnect the c ables at the alternator.

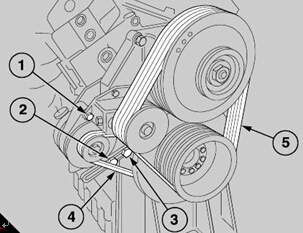

4 Loosen the pivot bolt (A1), the adjustment link bolt

(A2) and the bolt which holds the adjustment link to

the front mounting (A3). Remove the drive belt(s)

(A4).

5 Hold the alternator, remove the adjustment link and

the pivot bolt and lift away the alternator from the

engine.

To fit

1 Hold the adjus tment link for the alternator belt

against the front face of the front mounting of the

engine. Retain it loosely with its bolt, its nut and its

spring washer.

2 Hold the alternator between the support bracket

and the assembly of the tensioner pulley. Insert

loosely the pivot bolt, with a spring washer under its

head, through the bracket and the alternator and into

the threaded hole in the backplate of the pulley

assembly. Fit the bolt for the adjustment, with a plain

washer under its head, through the slot in the

adjustment link and through the lug of the alternator.

Fit loosely a plain washer, a spring washer and a nut

to the bolt.

3 Fit the drive belt(s) of the alternator around the

pulleys of the crankshaft and the alternator. Move the

alternator on the pivot bolt to tighten the belt(s). Refer

to section 4 of the User’s Handbook TSD 3138 for

details of how to adjust the tension of the alternator

belts. When the tension is correct, tighten securely

the two nuts on the bolts of the adjustment link and,

also, the pivot bolt of the alternator.

4 Connect the cables at the alternator.

5 For engines which are remotely cooled, fit the

alternator guard.

6 Connect the battery.

To dismantle and to assemble

拆卸和组装

To assemble

组装

1 Fit the spacer (A10) on the rotor shaft, with the large

1安装垫片(A10)在转子轴上,与大

diameter next to the rotor. Press the housing of the

转子的直径。按住房的

drive end and its bearing on to the rotor shaft. Apply

驱动端及其轴承在转子轴上。应用

pressure only to the inner race.

压力只有内在的比赛。

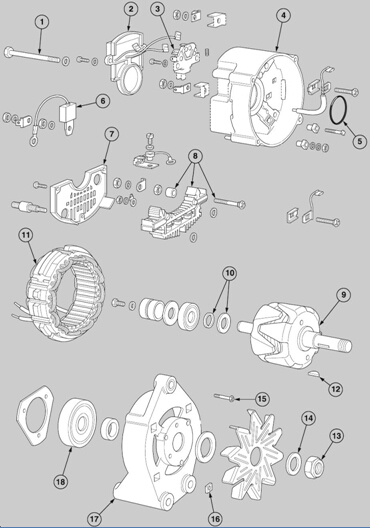

Before the alternator is dismantled, mark all housings

在交流发电机被拆除之前,所有的外壳都有

to ensure that their correct relationship is obtained

确保他们的正确关系得到

during assembly. For these operations, refer to the

在装配过程中。对于这些操作,指

illustration (A) on page 219.

插图(219页)。

1 Release the nut (A13) of the fan, remove the

1松开螺母(A13)的风扇,拆下

washer, the fan (A14) and the pulley. Remove the

洗衣机,风扇(14)和滑轮。拆下

’Woodruff’ key (A12) from the shaft and withdraw the

“半圆键(A12)从轴上取

spacer.

间隔。

2 Remove the suppression capacitor (A6) from the

2去除抑制电容器(A6)从

main output terminals, release the three screws and

主要输出端子,松开三个螺钉并

lift away the end cover (A7).

解除了端盖(A7)。

3 Remove the two screws and the ’Belleville’ washers

3取下两个螺钉和垫圈的碟形的

which retain the regulator (A2), and disconnect the

保持器(A2),并断开

’Luc ar’ terminals - two on the holder of the carbon

卢克AR的终端-两对碳架

brushes (A3) and one on the negative rectifier (A8).

刷子(A3)和一个负整流(A8)。

4 Disconnect the remaining ’Lucar’ terminal from the

4断开其余的卢卡的终端从

holder of the carbon brushes and lift away the

碳刷的持有人,并解除了

assembly of the holder.

持有人大会。

5 Remove the four sc rews (A15) and the square nuts

5删除四、螺丝钉(A15)和方形螺母

(A16) which are inserted in the housing of the drive

(A16),插入驱动住房

end.

结束。

6 Remove the long bolts (A1) and separate the

6去除长螺栓(A1)和分离

assembly of the rotor and the housing of the drive end

转子和驱动端的壳体的装配

from the assembly of the stator and the housing of the

从装配的定子和外壳的

slip ring end.

滑动环端。

7 Remove the three screws from the plate which

7从板中取出三颗螺丝

retains the bearing in the housing of the drive end

保留轴承在外壳的驱动端

(A17). Press out, or use a puller to remove, the

(A17)。压出,或用拉具拆卸,该

assembly of the rotor (A9) and the bearing (A18).

转子的装配(A9)和轴承(A18)。

8 Unsolder the three wires of the stator (A11) from the

8如果三线的定子(A11)从

assembly of the rectifier. Separate the stator from the

整流器组件。从定子中分离

housing of the slip ring end (A4).

滑环的端盖(A4)。

2 Fit a new ’O’ ring (A5) to the hous ing at the slip ring

2安装新的O型圈(A5)在滑环的住宅

end.

结束。

3 Inspect the insulation sleeves and renew them if

3检查绝缘套管,并将其更新

necessary. Fit the assembly of the stator to the

必要的。将定子装配到

housing of the slip ring end. Ensure that the bolt

滑动环端壳体。确保螺栓

holes, and the marks which indicate the correct

孔,并指出正确的标志

relationship of the housings, are aligned correctly.

外壳的关系,正确对齐。

4 Fit carefully the assembly of the rotor and the

4小心装配转子和转子

housing of the drive end into the assembly of the

驱动端的外壳进入装配的

stator and the housing of the slip ring end. Ensure

定子和壳体的滑动环结束。确保

that the bolt holes, and the marks which indicate the

螺栓孔,并标明了

correct relationship of the housings, are aligned

正确的关系的外壳,对齐

correctly.

正确。

5 Before the four long bolts are fitted, put a ’Belleville’

5前四个长螺栓安装,把一个“碟”

washer under each head. Tighten evenly the bolts to

每个头下的洗衣机。将螺栓均匀拧紧

the correct torque of 4.9 Nm (44.0 lbf in).

4.9 nm的正确的扭矩(44磅)。

6 Fit the assembly of the holder for the carbon

6安装碳源的支架

brushes, fit the screws and the ’Belleville’ washers

刷,安装螺丝和“碟形的垫圈

and tighten to 1.69 Nm (15.0 lbf in). Ensure that the

拧紧到1.69 nm(15磅)。确保

carbon brushes move freely in their holders.

碳刷自由移动在其持有人。

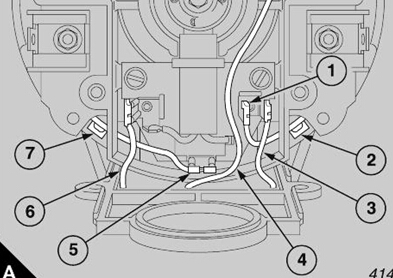

7 Connect the D+ and the F- cables to the Lucar

7将D和F -电缆卢卡

terminals as shown (A). Ensure that both of the

如图所示(一)。确保两者的

cables are retained under the internal lugs in the

电缆被保留在内部耳

casting.

铸造。

8 Use two screws and the ’Belleville’ washers to fit the

8用两个螺钉和垫圈的碟形的配合

regulator after the connections are made. Tighten

连接后的调节器。拧紧

evenly the screws to 1.69 Nm (15.0 lbf in).

均匀的螺丝1.69 nm(15磅)。

9 Bend the negative tags of the diodes down toward

9把二极管的负标记向下弯曲

the heat sink. Bend down each wire of the stator and

散热片。每根导线的弯曲

solder it to its tag, together with the wire of the

把它焊在标签上,连同电线

auxiliary diode. Solder the bottom face of each

辅助二极管。焊底面

positive tag, bend the tags around the wires of the

积极的标签,弯曲的电线上的标签

stator and solder the connections.

定子和焊连接。

10 Fit the end cover and tighten the three screws to

10安装端盖并拧紧三个螺钉

1.69 Nm (15.0 lbf in).

1.69 nm(15磅)。

11 Fit the suppression capacitor.

11配合的抑制电容。

To clean

清洁

1 All components should be cleaned thoroughly

1所有部件应彻底清洗干净

before they are inspected.

在他们被检查之前。

2 Remove all dirt and carbon from the components by

2去除所有的污垢和碳的组成部分

the careful use of compressed air and clean the stator

小心使用压缩空气和清洁定子

by the use of a cloth which is damp with white spirits.

用一种潮湿的布,白色的精灵。

To ins pect and to correct the rotor 23-4

INS PECT和纠正转子测量

1 Check the threads, the keyway s and the bearing

1检查螺纹、键槽、轴承

surfaces for damage.

损坏的表面。

2 Use a 110 volt 15 watt test lamp to test the

2使用一个110伏15瓦的测试灯来测试

insulation between the slip rings and the windings of

之间的滑动环和绕组的绝缘

the rotor, and the body of the rotor.

转子和转子的身体。

3 Use an ohmmeter to check the resistance of the

3用欧姆表检查的阻力

windings of the rotor. The resistance should be 14

转子绕组。电阻应为14

ohms ± 0.2 ohm at an ambient temperature of 20°C

±欧姆0.2欧姆在20°C环境温度

(68°F).

(68°)。

4 Check that the slip rings are concentric and are not

4检查滑环是否同心,不

worn or damaged. If necessary, check the tightness

磨损或损坏。如有必要,检查密封性

of the screw which retains the slip rings and use a

的螺丝,保留的滑动环和使用

lathe to remove only the minimum material from the

车床,以除去的最小材料从

rings. The minimum diameter is 24.69 mm (0.972 in).

环。最小直径为24.69毫米(0.972英寸)。

If the slip rings are badly worn or damaged they

如果滑环磨损严重或损坏

should be renewed as follows:

应更新如下:

5 Unsolder carefully the wires of the windings from

5如果仔细的绕组线

the pegs of the slip rings.

该滑环销钉。

6 Remov e the screw which retains the slip rings.

6移除螺丝保留滑环。

7 Withdraw the assembly of the slip rings from the

7撤回从中的滑动环的装配

shaft.

轴。

8 Align the wires from the windings of the rotor with

8将导线从转子的绕组中对齐

the slots in the assembly of the new slip rings.

新的滑环装配中的槽。

9 Press the assembly of the new slip rings onto the

9将新的滑动环装配到

shaft.

轴。

10 Fit the screw and the washer to retain the s lip

10安装螺丝和垫圈以保持嘴唇

rings. Tighten the screw to 2.3 Nm (20 lbf in).

环。拧紧螺钉2.3 nm(20磅)。

11 Wrap each wire from the windings of the rotor

11每根导线从转子绕组

approximately three turns around the relevant peg of

约三转的相关的挂钩

the slip rings and solder the connections.

滑动环和焊料连接。

12 Remove the surplus lengths of the pegs and

12拆下钉的剩余长度

remove all excessive solder so that the shape of the

除去所有过量的焊料,使其形状

pins and the wire can be seen.

引脚和电线可以看到。

To remove and to fit the rectifier

To test the main diodes with an ohmmeter or

1 Unsolder the D+ wire from the terminal of the

auxiliary diodes.

Caution: Do not try to turn the round section of the

negative terminal because it is retained by splines in

the negative rectifier.

2 Release the small nut, and remove the two spring

washers and the insulation bush from the inner side of

the housing.

3 From the outside of the housing, release the small

nut, and remove the ’Belleville’ washer and the ’Lucar’

terminal from the negative rectifier.

4 Remove the rectifier and ensure that the two

insulation washers are not lost, remove the square

headed bolt and the other insulation bush.

1 Insert an insulation bush and the square headed

bolt in the inner side of the housing. Fit the insulation

washer to the bolt on the outside of the housing.

2 Fit the insulation washer to the negative terminal on

the rectifier and insert the rectifier into the housing.

3 Fit the ’Lucar’ terminal, the ’Belleville’ washer and

the nut to the square headed bolt to retain the rectifier.

4 Fit correctly the insulation bush onto the negative

terminal on the inner side of the housing, fit the two

spring washers and the nut and tighten to 3.11 Nm

(26.5 lbf in).

5 Tighten the nuts which retain the rectifier to 2.0 Nm

(17 lbf in). Ensure that the ’Lucar’ terminal has

suitable clearance from the terminal of the auxiliary

diodes when the wires are fitted.

6 Solder the D+ lead onto the terminal of the auxiliary

Single diodes cannot be renewed. If a diode is found

to be faulty, the complete rectifier assembly must be

renewed. The diodes can be tested easily by the use

of an ohmmeter or by a 12 or 24 volt DC electrical

supply and a test lamp of low watts.

By the use of an ohmmeter

1 Connect one probe to the body of the rectifier and

the other probe to the connections of the three diodes

in sequence and check the resistances.

2 Check again with transposed probes to obtain a

reverse current.

3 These checks should show a low resistance in one

direction, and a very high resistance in the other

direction.

4 A low resistance in both directions indicates an

unserviceable diode.

5 A high resistance in both directions indicates that

there is no continuity in the circuit of the rectifier.

By the use of a test lamp

1 The test lamp should illuminate only in one

direction.

2 If the lamp illuminates in both directions, the diode

is unserv iceable.

3 If the lamp does not illuminate in either direction,

there is no continuity in the circuit of the rectifier.

To test the auxiliary diodes

23-7

To check and to renew the

carbon brushes

23-9

|

equipment and method as for the main diodes,

operation 23-6.

1 Put one probe on the terminal (at the point where

the D+ cable is soldered), and the other probe on

each of the three connections of the main diodes in

sequence. Transpose the probes to finish the check.

D+ and F- wires Caution: Do not try to turn the screws at the inner

side of the housing.

1 Remove the nut, the ’Belleville’ washer, the ’Lucar’

terminal and the guard of the terminal from the

outside of the housing. Remove the screws, the

terminal, and the insulator of the terminal from the

inner side of the housing.

2 Check the continuity and insulation of the D+ and

F- wires.

3 At the inner side of the housing fit the insulator for

the terminal. Ensure that the extension is toward the

bearing. Fit the terminal of the wire with the

connections toward the bearing and the openings

upward. Insert, correctly and fully, the square headed

section of the screw into the insulator.

4 From the outside of the housing, fit the guard of the

terminal, the ’Lucar’ terminal, the ’Belleville’ washer

and the nut. Tighten the nut to 3.11 Nm (26.5 lbf in).

|

1 Check the holder of the carbon brushes for signs of

damage and especially for cracks.

2 Chec k the carbon brushes for damage and ensure

that they are suitable for use. The minimum possible

protrusion of the carbon brushes from the holder must

be 10.0 mm (0.394 in).

To renew

1 Unsolder the wires of the carbon brushes from the

terminals and withdraw the carbon brushes from the

holder. Keep the insulation sleeves if they are

suitable for further use.

2 Fit the sleeves to the wires of the new carbon

brushes and insert them through the centre of the

spring and through the s mall hole.

3 Pull the wire of the carbon brush until the maximum

projection of the carbon brush is 15.0 mm (0.590 in).

Wrap the wire one complete turn around the terminal

and solder the connection. Remove all s urplus wire.

the housing 23-10

1 Check the windings of the stator for burned or

broken wires, and for damage to the insulation.

2 Use a 110 volt 15 watt test lamp to test the

insulation between the body of the stator and each of

the three wires in turn.

3 Check the resistance between two wires and check

all of the wires in sequence. Resistance across two

phases should be 0.485 ohms.

To inspect the bearings

The bearings are sealed for life and do not need a

service.

Caution: Original bearings should be checked for

wear or roughness when they are operated. The

bearing at the drive end has integral seals which

should be checked for damage or distortion. If the

condition of the original bearings is in doubt, new

bearings should be fitted.

|

|

23-4 paragraphs 5 to 7.

2 Remove the deflector type washer.

3 Press, or use a puller to remove, the bearing from

the rotor s haft. Remove the spacer and the thin

washer.

4 Check the wires and return them to the grooves. Fit

the thin washer and the spacer.

5 Press the new bearing onto the shaft. Apply

pressure only to the inner race.

6 Fit the deflector type washer and fit the assembly of

the slip rings on the rotor shaft, operation 23-4

paragraphs 8 to 12.

drive end

or use a puller to remove, the bearing from

the rotor shaft. Ensure that the spacer is not lost and

make a note that the tapered side is toward the

bearing.

2 Press the new bearing into the housing of the drive

end. Apply pressure only to the outer race.

3 Fit the plate which retains the bearing. Use ’Loctite

242’ on the threads of the screws and tighten the

three screws to 1.69 Nm (15.0 lbf in).

400-100-8969 15088860848

0574-26871589 15267810868

0574-26886646 15706865167

0574-26871569 18658287286

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文(简)

中文(简) Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska