MTU柴油机燃油喷射系统的特点

8000系列则采用了高压共轨燃油喷射、相继增压(STC)和柴油机控制型发动机管理系统(MDEC)等技术。其高压共轨燃油系统是建立在直喷技术、预喷射技术和电控技术基础之上的一种全新概念的喷油系统,其特点为:喷油压力的建立与喷油过程无关;喷油压力、喷油过程和喷油持续期不受负荷和转速的影响;喷油定时与燃油计量完全分开;可以自由调整每缸的喷油量和喷油始点;能实现预喷射、快速停喷、后喷射和多段喷射等。而相继增压系统则进一步扩大了柴油机的功率范围,并使发动机在低、中等输出

功率时有优越的加速性能、显著降低柴油机燃油消耗率和排放水平、延长了发动机两次维修之间的时间、经济性和可靠性得到了进一步提高,MTU柴油机|MTU柴油机燃油喷射系统的特点维修技术|MTU柴油机燃油喷射系统的特点资料|MTU柴油机燃油喷射系统的特点维修服务商技术水平更为先进,整体性能更为优越。 3 MTU燃油喷射系统的工作原理和优点

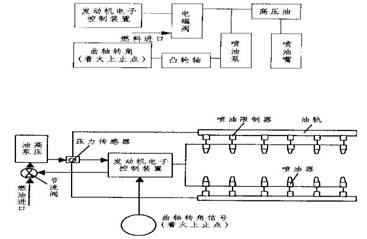

2000系列柴油机采用由电磁阀控制的单泵燃油

电子喷射系统。该系统由电磁阀控制的单体泵—高压油管—喷油嘴组成。每个气缸都有一个对应的单体泵,单体泵安装在柴油机的 V形槽中,由凸轮轴进行驱动,凸轮的轮廓线可根据柴油机的不同用途进行专门设计。安装在单体泵燃油进口处的电磁阀受柴油机电子控制系统控制,任一缸的喷油量和供油始点都通过控制电磁阀开关来实现,并且喷油量和供油始点可由柴油机电子控制系统进行任意调节,从而实现了喷油优化。

图 1单泵燃油电子喷射系统原理图

MTU diesel engine fuel injection system features

MTU2000 and 4000 series are 8, 12 and 16-cylinder, three kinds of models, the 8000 Series, 12, 16 and 20 cylinder models. 2000 and 4000 series models using the MTU of the order of the development of the supercharger, Split cooling system, exhaust manifold of the three-layer wall structure is advanced, mature technology; advanced electronic control system, fuel system, using advanced electronic injection technology (including the single-pump fuel electronic injection system and high pressure common rail electronic injection system). So that they can adapt to a variety of different purposes, to change the configuration of its attachment or certain parts of the structure, you can meet the needs of the ship, rail and heavy road vehicles, and other industrial fields; long service life, reliability, The use of easy maintenance, repair and maintenance of small workload; low fuel consumption, power, economy, reliability, advanced noise and vibration emissions targets.

The 8000 Series uses a high pressure common rail fuel injection, sequential turbocharging (STC) and diesel-controlled engine management system (MDEC) technology. The high pressure common rail fuel system is the establishment of a direct injection technology, fuel injection system of pre-injection technology and electronic control technology on the basis of a new concept, which is characterized by: the establishment of the injection pressure and injection process; injector pressure from the effects of load and speed of the injection process and the injection duration; completely separate from the fuel injection timing and fuel metering; can freely adjust each cylinder fuel injection quantity and fuel injection starting point; to achieve the pre-injection, fast Minting, after injection and multi-stage injection and so on. Sequential turbocharging system to further expand the power range of diesel engines and engines at low and medium output

Superior acceleration performance, significantly reduce diesel fuel consumption and emission levels, to extend the time between maintenance of the engine twice when the power, economy and reliability has been further improved, more advanced technical level, the overall performance is superior to . MTU fuel injection system works and benefits

2000 series diesel engine using a single pump controlled by a solenoid valve fuel

The electronic injection system. The system consists of a solenoid valve control unit pump - high pressure tubing - nozzle. Each cylinder has a corresponding unit pump, unit pump installed in the diesel V-shaped slot, driven by the camshaft, cam contour can be specifically designed according to the different uses of diesel engines. Solenoid valve installed in the unit pump fuel imports by the diesel engine electronic control system to control any one-cylinder fuel injection quantity and fuel supply starting point by controlling the solenoid valve switch to achieve, and the fuel injection quantity and fuel supply starting point may be a diesel engine electronic control The system of arbitrary regulation, in order to achieve a fuel injection optimization.

Figure schematic of a single pump fuel electronic injection system

400-100-8969 15088860848

0574-26871589 15267810868

0574-26886646 15706865167

0574-26871569 18658287286

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文(简)

中文(简) Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska