柴油机的调速系统与操纵系统的俭修

为了保证柴油机压缩空气起动迅速可靠,必须具备以下三个条件:

(1)压缩空气必须具有一定的压力和储量;

(2)压缩空气供气要适时并有一定的供气延续时间;

(3)必须要保证有最少气缸数。

2、压缩空气起动装置的主要设备

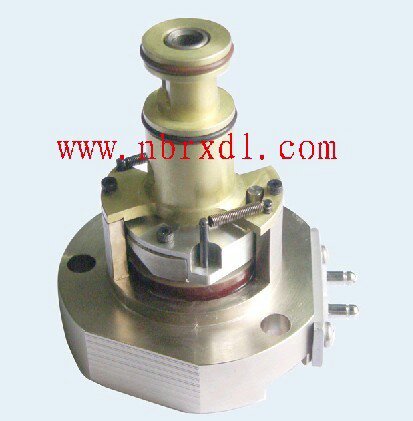

(1)气缸起动阀

气缸起动阀是起动装置中最主要的部件之一。通常,每缸一个均装在气缸盖上,其下方与起动空气总管连接,上方与空气分配器连接。其动作由空气分配器按发火顺序使起动空气进入气缸,完成起动动作。

气缸起动阀分为单向阀式和气压控制式两种。前者为一个简单的单向阀,其起动空气与控制空气合并由空气分配器控制。后者,开阀的控制空气与进入气缸的起动空气分开输送。

(2)空气分配器

空气分配器由凸轮轴驱动。它的作用是按照柴油机的发火顺序,在要求的起动正时时刻内将控制空气分配器到相应的气缸起动阀使之开启,让压缩空气进入气缸,起动柴油机。

(3)主起动阀

主起动阀是压缩空气系统的总开关,用来起闭空气瓶至空气分配器和气缸起动阀间的主起动空气通路;在起动操纵时来自空气瓶的压缩空气经主起动阀迅速进入起动空气总管,并经总管分至各缸气缸起动阀和空气分配器,使启动迅速可靠并减少压缩空气的节流损失;当启动完毕后,它能迅速切断进入起动总管的压缩空气,并使总管中的残余空气经主起动阀进入大气。因此,在大、中型柴油机压缩空气起动装置中多设有主起动阀。

3、压缩空气起动系统常见故障分析

(1)柴油机不能起动

当起动手柄或手轮推至起动位置时,如果柴油机没有转动,其主要原因在起动系统。可能的原因有以下几个方面:

① 盘车机未脱开,起动控制空气处于关闭状态;

② 空气瓶出口阀或主截止阀未开足;

③ 起动空气压力不足;

④ 起动空气管系脏污,空气流量不足;

⑤ 起动空气系统中的有关阀件,如主起动阀、起动控制阀、空气分配器、气缸起动阀

等卡死、磨损、漏气。

(2)起动时曲轴转动但达不到发火所需的转速

可能的原因和解决的办法如下:

① 起动空气压力太低,应予补充;

② 柴油机暖缸不足,滑油粘度太大,应予暖缸;

③ 起动操纵过快,应重新起动;

④ 个别气缸起动阀或空气分配器咬死或动作不灵活,应检查、拆卸清洗。

(3)某一段起动空气管发热

通常是该缸起动阀泄漏所致。应检修漏气的起动阀。

二、柴油机换向装置

换向装置常见故障分析:

属于换向机构的故障有:

① 换向机构中有阀件咬死;

② 换向伺服器故障:堵塞、漏油、转板在极端位置咬死或不能到达另一极端位置;

③ 空气分配器故障。

属于操作不当的有:

① 操作过快,凸轮轴尚未到位就急于起动使换向失败;

② 换向手柄虽已到位,但由于水流作用使螺旋桨仍按原转向以较高转速转动,此时急

于起动而使换向失败;

③ 在紧急刹车时,过于性急,强制制动的时机不当,使转向失败。

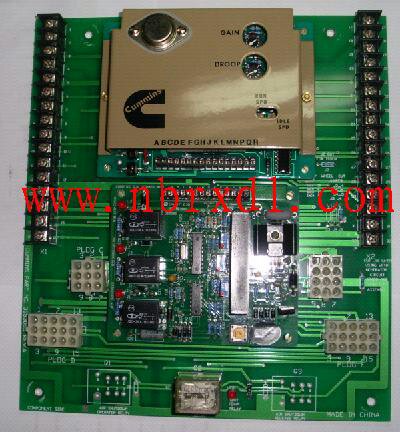

三、柴油机调速器的故障分析

当柴油机在工作中转速变化出现异常时,通常应考虑以下三个方面的因素:柴油机工

作性能恶化;调速器某些辅助设备失常;调速器本身失常。因此,应首先进行以下检查:

(1)确认柴油机的负荷是否超出了柴油机的标定负荷;

(2)检查各缸的负荷是否严重的不均,是否正常发火,喷油器是否处于正常的工作状态;

(3)检查调速器与喷油泵之间的杠杆传动机构是否卡滞和间隙过大而松动;

(4)检查调速器负荷指针的零位与喷油泵的零位是否一致;

(5)检查调速器的设定机构、控制空气压力是否正常。

当进行以上检查并排除后,如调速器工作仍然不正常,则为调速器的自身故障,这些故障通常有:

1、柴油机游车或转速振荡

游车指转速有节奏地变化,以手动停住调速器的作用时可以消除,但放手后仍会有节奏的转速变化。转速振荡指转速有节奏变化且幅度较大,手动停住调速器作用可消除波动,放手后转速不会立即重新波动,但在调速或负荷变化后波动仍会发生,可能的原因有:

(1)调速器反馈系统调速不当,应重新进行稳定性调节;

(2)调油杆、高压油泵空动或卡死;

(3)调速器滑油太脏、起泡或油位太低(油位表不见油位);

(4)调速器内部故障,如飞重和轴承磨损、滑阀卡死、补偿(阻尼)弹簧弹性失效等;

(5)调速器与柴油机不匹配。

2、调速器输出轴颤动(高频振动)

可能的原因有:

(1)调速器驱动不稳。如传动齿轮磨损、啮合不良、凸轮轴传动机构松动、柴油机减振器故障等;

(2)飞重的弹性驱动机构故障;

(3)调速器在安装支座上没有均匀紧固。

3、柴油机达不到全速全负荷

可能的原因有:

(1)喷油泵齿条拉出长度不够或调速器输出轴已达到最大输出行程(刻度10)。这可能是由于调油杆系卡滞、空动,调速器输出轴与喷油泵供油刻度匹配不当等因素引起;

(2)控制空气或扫气空气压力太低或设定转速太低;

(3)动力活塞运动受阻;

(4)液压系统油压过低或油路堵塞。

4、柴油机起动时高压油泵齿条不能及时拉开

可能的原因有:

(1)调速器中油压低,如齿轮泵磨损、齿轮泵单向阀泄漏;

(2)起动转速太低;

(3)升压伺服器(在起动时刻使用起动空气迅速增加调速器内滑油压力的选用设备)动作不佳;

(4)某种断油机构(如停车螺帽等)调整不当;

(5)转速设定值或扫气压力燃油限制器(在起动时由扫气压力限定调速器输出轴转角的一种辅助装置)设定值太低。

Frugality of speed control system and control system of diesel engineA diesel engine starter

Diesel engines under the forces for air intake, compression, injection, combustion until fuel runs silently expansion work, which

According to a process of diesel engine starting. Starting speed of general scope are:

High speed diesel engine 80~150 r/min; 60~70 r/min medium speed diesel engines; low-speed diesel engine 25~30 r/min.

1, the composition and working principle of compressed air Starter

Compressed air Starter is a certain pressure of compressed air, diesel engines introduced when the expansion stroke cylinder in the firing order, promote the piston to make diesel engines meet the starting speed, complete the firing on their own.

In order to ensure speedy and reliable diesel engine compressed air starter, you must meet the following three conditions:

(1) compressed air must have a certain amount of pressure and reserves;

(2) the compressed air supply to duration and there is a certain amount of gas supply in due time;

(3) the need to ensure that at least the number of cylinders.

2 major equipment, compressed air Starter

(1) the cylinder valve

Cylinder valve is one of the most important parts in the starter. Typically, each cylinder mounted on a cylinder head, beneath it with starting air duct connection, connect with air Distributor at the top. Their movements by the air distributor firing order for starting air into the cylinder, complete starting action.

Starting valve cylinder divided into valves and pressure control in two ways. The former is a simple one-way valve, its starting air merged with controlled air is controlled by air Distributor. The latter, open control valve separate starting air conveying of air and into the cylinder.

(2) air distributor

Air distributor driven by the camshaft. Its role is in the diesel engine firing order, at the request of the starting time will be control air distributor to the appropriate cylinder valve to make it open, let compressed air into the cylinder, starting diesel engines.

(3) main starting valve

Main since dynamic valve is compression air system of total switch, used to since closed air bottle to air Distributor and cylinder since dynamic valve between of main since dynamic air pathway; in since dynamic manipulation Shi from air bottle of compression air by main since dynamic valve quickly entered since dynamic air duct, and by duct min to the cylinder cylinder since dynamic valve and air Distributor, makes started quickly reliable and reduced compression air of throttle loss; Dang started finished Hou, it can quickly cut off entered since dynamic duct of compression air, and makes duct in the of residual air by main since dynamic valve entered atmospheric. Therefore, in large and medium diesel engine compressed air Starter has the primary valve.

3, compressed air brake system trouble analysis

(1) diesel engine not start

When the starting handle or push the handwheel to start position, if the diesel engine is not turning, the main reasons in the starting System. Possible reasons are the following aspects:

① Turning does not disengage, starting control of air in a closed state;

② air cylinder outlet valve or the main stop valve was not full;

③ insufficient starting air pressure;

④ starting air pipe dirt, lack of air flow;

⑤ starting air about valves in the system, such as the main starting valve, control valve, air Distributor, the cylinder valve

Card dead, damaged and leakage.

(2) the crankshaft rotation when starting but does not meet the required for the combustion speed

Possible causes and solutions are as follows:

① starting air pressure is too low and should be supplemented;

② diesel engine warm-cylinder insufficient lubricating oil viscosity is too large and should be warm-cylinder;

③ Start manipulating too quickly and should be starting afresh;

④ individual cylinder valve or air distributor bitten to death or the action is not flexible, you should check and removal of cleaning.

(3) a period of starting air pipe heating

Is usually caused by leakage of the valve from the cylinder. Starting valve leakage inspection and repair.

Second, diesel engine reversing device

Common fault analysis of commutation device:

Belonging to the reversing gear failures are:

① reversing valves of the bodies killed;

② commutation server failure: plug, oil spills, transfer Board, or bitten to death in extreme locations cannot reach the other extreme position;

③ Air distributor fault.

Belonging to the improper operation of:

① actions too quickly, camshaft is not yet in place is eager to start making your reversal fails;

② the reversing handle has in place, but because of the steady flow by the propeller on an original shift to high speed rotation, acute

On commutation failure as a Starter;

③ When the emergency brakes, too impatient, inappropriate timing of forces the brake, causing the steering to fail.

Third, speed Governor of diesel engine fault analysis

Engine speed changes when an exception occurs in the work, typically you should consider the following three factors: diesel

Performance deterioration of Governors of certain auxiliary equipment malfunction; Governor disorder in itself. Therefore, you should first check the following:

(1) confirm that the diesel engine load beyond the calibration of diesel engine load;

(2) check whether the load each cylinder serious inequality, whether normal combustion, fuel injector is in good working condition;

(3) check the Governor with fuel injection pump lever actuator is stuck between-delay and gap too large and loose;

(4) check the Governor load pointer to zero-zero digits are consistent with the injection pump;

(5) checks whether a Governors constituted body, control of air pressure is normal.

When you make these checks and after excluding, as Governor is still not working properly, the Governor's own fault, these failures usually are:

1, traveling or diesel engine speed oscillation

Traveling speed changes in rhythm, to manually stop Governor's role can be eliminated, but is let go after rhythmic speed changes. Speed oscillation means rhythm changes in speed and range is large, manually stop Governor eliminates fluctuations, fluctuations in speed does not immediately after letting go, but after the changes in speed or load fluctuations may occur, possible causes are:

(1) the Governor feedback system speed properly renewed stability should be adjusted;

(2) adjustable rod, high pressure pumps air or blockage;

(3) the Governor oil too dirty, bubbles or oil level is too low (see oil level oil level table);

(4) internal fault of Governors, flies and bearing wear, sliding valves stuck, compensation (damping) elasticity of spring invalidation;

(5) the Governor with diesel engines do not match.

2, speed of the output axis quiver (high-frequency vibrations)

Possible reasons are:

(1) the Governor-driven instability. Transmission gear worn loose, poor meshing, camshaft gear, engine shock absorber failure;

(2) flexible drive mechanism failure on the fly;

(3) the Governor does not have the install pedestal tighten evenly.

3, diesel engines are not up to full speed at full load

Possible reasons are:

(1) pull the fuel pump racks length is insufficient to trip the Governor output shaft or has reached the maximum output (scale of 10). This may be due to oil linkage block, air motion, Governor output shaft and injection pump oil supply caused by improper matches the scale factor;

(2) controlling air or scavenge air pressure too low or set speed is too low;

(3) the power piston is blocked;

(4) hydraulic system pressure too low or the oil plug.

4, when the diesel engine starting fuel pump wires can not be timely opened

Possible reasons are:

(1) the Governor oil pressure, such as gear pump wear, gear pump check valve leaks;

(2) starting speed is too low;

,, , , (3) boost server (at starting point using the rapid increase in the starting air Governor selection of lubricating oil pressure equipment in) poor actions;

(4) a certain oil bodies (such as stopping nuts) improper adjustments;

(5) speed settings or scavenge pressure fuel limiter (at the time of starting qualified by a sweep gas pressure Governor output shaft rotation of an assistive device) set value is too low. Frugality of speed control system and control system of diesel engine

A diesel engine starter

Diesel engines under the forces for air intake, compression, injection, combustion until fuel runs silently expansion work, which

According to a process of diesel engine starting. Starting speed of general scope are:

High speed diesel engine 80~150 r/min; 60~70 r/min medium speed diesel engines; low-speed diesel engine 25~30 r/min.

1, the composition and working principle of compressed air Starter

Compressed air Starter is a certain pressure of compressed air, diesel engines introduced when the expansion stroke cylinder in the firing order, promote the piston to make diesel engines meet the starting speed, complete the firing on their own.

In order to ensure speedy and reliable diesel engine compressed air starter, you must meet the following three conditions:

(1) compressed air must have a certain amount of pressure and reserves;

(2) the compressed air supply to duration and there is a certain amount of gas supply in due time;

(3) the need to ensure that at least the number of cylinders.

2 major equipment, compressed air Starter

(1) the cylinder valve

Cylinder valve is one of the most important parts in the starter. Typically, each cylinder mounted on a cylinder head, beneath it with starting air duct connection, connect with air Distributor at the top. Their movements by the air distributor firing order for starting air into the cylinder, complete starting action.

Starting valve cylinder div, ided into valves and pressure control in two ways. The former is a simple one-way valve, its starting air merged with controlled air is controlled by air Distributor. The latter, open control valve separate starting air conveying of air and into the cylinder.

(2) air distributor

Air distributor driven by the camshaft. Its role is in the diesel engine firing order, at the request of the starting time will be control air distributor to the appropriate cylinder valve to make it open, let compressed air into the cylinder, starting diesel engines.

(3) main starting valve

Main since dynamic valve is compression air system of total switch, used to since closed air bottle to air Distributor and cylinder since dynamic valve between of main since dynamic air pathway; in since dynamic manipulation Shi from air bottle of compression air by main since dynamic valve quickly entered since dynamic air duct, and by duct min to the cylinder cylinder since dynamic valve and air Distributor, makes started quickly reliable and reduced compression air of throttle loss; Dang started finished Hou, it can quickly cut off entered since dynamic duct of compression air, and makes duct in the of residual air by main since dynamic valve entered atmospheric. Therefore, in large and medium diesel engine compressed air Starter has the primary valve.

3, compressed air brake system trouble analysis

(1) diesel engine not start

When the starting handle or push the handwheel to start position, if the diesel engine is not turning, the main reasons in the starting System. Possible reasons are the following aspects:

① Turning does not disengage, starting control of air in a closed state;

② air cylinder outlet valve or the main stop valve was not full;

③ insufficient starting air pressure;

④ starting air pipe dirt, lack of air flow;

⑤ starting air about valves in the system, such as the main starting valve, control valve, air Distributor, the cylinder valve

Card dead, damaged and leakage.

(2) the crankshaft rotation when starting but does not meet the required for the combustion speed

Possible causes and solutions are as follows:

① starting air pressure is too low and should be supplemented;

② diesel engine warm-cylinder insufficient lubricating oil viscosity is too large and should be warm-cylinder;

③ Start manipulating too quickly and should be starting afresh;

④ individual cylinder valve or air distributor bitten to death or the action is not flexible, you should check and removal of cleaning.

(3) a period of starting air pipe heating

Is usually caused by leakage of the valve from the cylinder. Starting valve leakage inspection and repair.

Second, diesel engine reversing device

Common fault analysis of commutation device:

Belonging to the reversing gear failures are:

① reversing valves of the bodies killed;

② commutation server failure: plug, oil spills, transfer Board, or bitten to death in extreme locations cannot reach the other extreme position;

③ Air distributor fault.

Belonging to the improper operation of:

① actions too quickly, camshaft is not yet in place is eager to start making your reversal fails;

② the reversing handle has in place, but because of the steady flow by the propeller on an original shift to high speed rotation, acute

On commutation failure as a Starter;

③ When the emergency brakes, too impatient, inappropriate timing of forces the brake, causing the steering to fail.

Third, speed Governor of diesel engine fault analysis

Engine speed changes when an exception occurs in the work, typically you should consider the following three factors: diesel

Performance deterioration of Governors of certain auxiliary equipment malfunction; Governor disorder in itself. Therefore, you should first check the following:

(1) confirm that the diesel engine load beyond the calibration of diesel engine load;

(2) check whether the load each cylinder serious inequality, whether normal combustion, fuel injector is in good working condition;

(3) check the Governor with fuel injection pump lever actuator is stuck between-delay and gap too large and loose;

(4) check the Governor load pointer to zero-zero digits are consistent with the injection pump;

(5) checks whether a Governors constituted body, control of air pressure is normal.

When you make these checks and after excluding, as Governor is still not working properly, the Governor's own fault, these failures usually are:

1, traveling or diesel engine speed oscillation

Traveling speed changes in rhythm, to manually stop Governor's role can be eliminated, but is let go after rhythmic speed changes. Speed oscillation means rhythm changes in speed and range is large, manually stop Governor eliminates fluctuations, fluctuations in speed does not immediately after letting go, but after the changes in speed or load fluctuations may occur, possible causes are:

(1) the Governor feedback system speed properly renewed stability should be adjusted;

(2) adjustable rod, high pressure pumps air or blockage;

(3) the Governor oil too dirty, bubbles or oil level is too low (see oil level oil level table);

(4) internal fault of Governors, flies and bearing wear, sliding valves stuck, compensation (damping) elasticity of spring invalidation;

(5) the Governor with diesel engines do not match.

2, speed of the output axis quiver (high-frequency vibrations)

Possible reasons are:

(1) the Governor-driven instability. Transmission gear worn loose, poor meshing, camshaft gear, engine shock absorber failure;

(2) flexible drive mechanism failure on the fly;

(3) the Governor does not have the install pedestal tighten evenly.

3, diesel engines are not up to full speed at full load

Possible reasons are:

(1) pull the fuel pump racks length is insufficient to trip the Governor output shaft or has reached the maximum output (scale of 10). This may be due to oil linkage block, air motion, Governor output shaft and injection pump oil supply caused by improper matches the scale factor;

(2) controlling air or scavenge air pressure too low or set speed is too low;

(3) the power piston is blocked;

(4) hydraulic system pressure too low or the oil plug.

4, when the diesel engine starting fuel pump wires can not be timely opened

Possible reasons are:

(1) the Governor oil pressure, such as gear pump wear, gear pump check valve leaks;

(2) starting speed is too low;

(3) boost server (at starting point using the rapid increase in the starting air Governor selection of lubricating oil pressure equipment in) poor actions;

(4) a certain oil bodies (such as stopping nuts) improper adjustments;

(5) speed settings or scavenge pressure fuel limiter (at the time of starting qualified by a sweep gas pressure Governor output shaft rotation of an assistive device) set value is too low.

400-100-8969 15088860848

0574-26871589 15267810868

0574-26886646 15706865167

0574-26871569 18658287286

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文(简)

中文(简) Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska