船舶柴油发动机气缸盖裂纹原因与维修

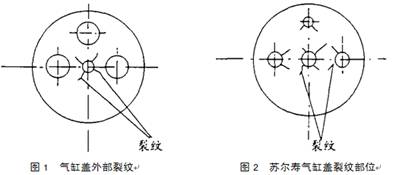

柴油机气缸盖不仅结构复杂,而且工作条件、受力情况也十分复杂、恶劣。气缸盖的底面直接与高温高压燃气接触,不仅受到高温高压燃气的腐蚀与冲刷,而且周期地承受较高的机械负荷与热负荷;底面在燃气的爆发压力作用下产生很大的机械应力,壁厚与温度的不均匀导致较高的热应力;螺栓的预紧力使气缸盖承受着压应力,并与燃气压力共同作用使气缸盖受到弯曲作用,在截面变化处会产生应力集中等。此外,冷却水腔还受到水的腐蚀。 正是由于气缸盖如此恶劣的工作条件,致使气缸盖很容易损坏。通常损坏形式为:其底面和冷却水腔容易产生裂纹,还有气阀底面和导套容易磨损,冷却水侧被腐蚀等。 本文主要针对船舶柴油机气缸盖最经常出现的损坏现象——裂纹,进行详细叙述,分析其裂纹产生原因极其修理、预防措施等。 一.气缸盖裂纹产生的部位 船用柴油机气缸盖的裂纹主要发生在气缸盖底面有应力集中的地方,如孔与孔之间或孔的圆角处、冷却水腔的截面变化处等。产生裂纹的具体部位则随机型、气缸盖的结构和材料不同而异。 船用四冲程柴油机在进排气阀孔和喷油器等孔之间以及阀座面上容易产生裂纹。当裂纹产生在底面时,多为径向裂纹;当裂纹产生在外部时,裂纹大多是从中央喷油器孔向进排气阀孔扩展,这是由于小孔处的应力集中所致(如图1所示)。 苏尔寿RD和RND型柴油机气缸盖,裂纹大多发生中央小缸盖底面上的喷油器孔、启动阀孔、安全阀孔四周的圆角处,多沿径向扩展(如图2所示) [1]。 MAN型柴油机气缸盖由上下两部分组成,下半部分用耐热合金铸铁制成,主要承受热负荷;上半部分采用灰口铸铁制成,主要承受机械负荷,由于下半部分缸盖冷却水腔布置了环形冷却水道,故裂纹多 2 气缸盖产生裂纹的原因 气缸盖产生裂纹是气缸盖较为常见的故障。气缸盖产生裂纹的根本原因是热应力和机械应力周期性的作用。在交变的热应力和机械应力的作用下,将产生疲劳裂纹,从而导致气缸盖裂纹。具体分析气缸盖产生裂纹主要有以下几个方面原因。 1 结构设计上的原因 气缸盖底面气阀孔周围之所以常产生裂纹,主要因为该处有较大的表面积,因此,受热膨胀和冷却时收缩速度都较大。例如,柴油机工作一段时间停车后,气缸盖温度分布变化剧烈,热量通过冷却水和进排气通道迅速散发,所以在气阀孔处容易产生裂缝。 再者,由于结构或受力不合理、过度圆角太小等均会引起过大的机械应力,从而导致裂纹。 2 材料和工艺上的原因 气缸盖材料选择不当,质量不符合要求,铸造时没有很好地消除铸造应力,从而导致零件内部有缺陷,从而使气缸盖在工作时容易产生裂纹。 3 装配质量上的原因 气缸盖螺栓不按规定交叉拧紧,或在发生气缸盖平面漏气时拧紧该处的螺母来解决,都会造成气缸盖受力不均匀而产生裂纹。喷油器安装不正确,会引起气缸盖底面局部变形,增大喷油器孔处所受的拉应力,使之容易产生裂纹。 4 操作和管理上的原因 柴油机长期在超负荷条件下运转或在未充分暖缸的情况下突然增大负荷,使气缸盖从冷态急剧变为热态,或在高温下急剧冷却而产生裂纹。 柴油机冷车启动或启动后加速太快,致使气缸盖底面与冷却面温差过大,热应力增大。故应暖机后再启动,启动后待油、水温度升高后方可加速;频繁启动、停车和长期超负荷运转均会使机械应力和热应力增加;冷却与润滑不足或中断,亦会导致机件过热。 5 维护保养不良的原因 安装气缸盖时未按规定上紧螺栓,个螺栓受力不均,使气缸盖产生过大的附加应力;长期使用,未清洁冷却水道,致使水腔积垢,影响散热,引起过大的热应力,从而导致裂纹的产生。 3 气缸盖疲劳裂纹 1 热疲劳裂纹 在底板受热面“鼻梁区”产生热疲劳裂纹是四冲程柴油机气缸盖较为常见的损坏形式。产生热疲劳是由于受热面的温度超过材料的使用极限而发生蠕变,引起塑性变形。当气缸盖在冷热交替情况下工作时,受热面的收缩性变形而受阻,从而产生残余拉伸应力。受热面温度超过极限温度越多,运行时间越长,残余拉伸应力就越大,最终因应力的反复交变而出现疲劳裂纹。严重时可能经过一次冷热循环便出现裂纹[5]。 2 机械疲劳裂纹 气缸盖底板在缸内气体压力作用下发生周期性弯曲变形,其最大拉伸应力发生于底板的内侧表面,阀孔尖角处应力集中严重,再叠加上热应力(底板内侧表面所受热应力也为拉伸应力)的作用,于是机械疲劳裂纹以此尖角为起点,沿阀孔周围逐渐向受热面扩展而裂穿。 3 腐蚀疲劳裂纹 冷却水中含有各种酸根离子和溶解氧将对金属发生电化学腐蚀和氧化,金属晶界是首先被腐蚀和氧化的部位。这将导致被腐蚀的表面变得粗糙并产生应力集中,使材料的疲劳强度显著下降。又由于气缸盖与气缸套的圆锥部分配合不良,以及气缸盖螺栓的过分紧固,在柴油机运转时,使密封凸缘冷却水侧产生较大的脉动机械应力。在腐蚀和较大的脉动机械应力共同作用下,从冷却水侧开始发生腐蚀疲劳裂纹。 4 气缸盖裂纹检查 通常,气缸盖裂纹都有一个产生和发展的过程,因此,平时认真检查、仔细观察、及早发现,就能避免机损事故的发生。气缸盖裂纹检查主要有3种方法:直接观察法、着色探伤法、液压试验法。 1 直接观察法 可根据冷却水压力表指针的摆动和膨胀水箱中水位的上下波动及有无气泄、油渍等来判断气缸盖是否有裂纹,还可通过示功阀检查排气是否冒白烟或有燃烧不良现象来判断裂纹发生在哪一缸。经常检查曲轴箱中滑油油位的变化,若油位升高,油中水分明显增加,则应怀疑内有裂纹。 2 着色探伤法 着色探伤渗透液是含有红色颜料、溶剂和渗透剂等成分。具有渗透力强,渗透速度快,显象时清晰醒目,洗涤性好,化学稳定性好和无腐蚀或低毒等特点。显象剂常为氧化锌、氧化镁或二氧化钛等白色粉末和有机溶剂组成。显象剂具有悬浮力好,与渗透液有明显的衬度对比,显示缺陷清晰,易于辨别,无腐蚀性等特点。 在着色探伤操作中有浸液法、刷涂法和喷涂法。内压式喷灌操作简单,携带方便,广为应用。一组内压式喷灌各装有清洗剂、渗透剂和显象剂。检验时,先用清洗剂清洁零件待检表面,然后喷涂一层渗透剂,依据材料不同有不同的渗透时间。如常温下铝、镁合金铸件约为15分钟,锻件和钢铸件应不小于30分钟;钢焊件和焊缝有的可打60分钟;塑料、玻璃、陶瓷等非金属材料在5~30分钟之间。渗透剂渗透时间对检验灵敏度影响很大。时间短,小缺陷难以发现,大缺陷显示不全;时间长,难以清洗和检验效率低。在清洗掉表面渗透剂后再喷涂显象剂,最后就可在白色衬底上显示出红色缺陷痕迹。 3 液压试验法 对于内部微小裂纹,如冷却水腔的微小裂纹,用着色法很难检查,通常做液压试验才能检查出来。 液压试验法实质上是在模拟使用条件下对承压零件材料内部有无缺陷进行检验的一种无损检验方法。它不需任何先进的仪器,只用一般的专用夹具和具有压力的气体或液体。 液压试验前,将待检零件上的孔、洞等全部堵塞,用专用夹具密封零件形成包括检验部位的密封空腔,注满液体或气体后完全封闭,按要求加压至规定试验压力,保持一定时间后观察零件外表面上有无液体渗出或气体逸出,从而判断零件有无裂纹。 试验用液体可用水或油,也可用空气,以有关要求而定。试验压力以零件工作条件而定。柴油机气缸盖冷却水腔试验压力为0.7MPa,保持5分钟。另外,航行中根据下列现象判断燃烧室零件有无穿透性裂纹: 1)柴油机运转中,轮机员可根据气缸或活塞冷却水表压力指针波动或膨胀水柜水位上下波动判断零件有穿透性裂纹。因为当气缸盖或气缸套有穿透性裂纹时,燃烧室中的高压燃气就会沿裂缝进入冷却水腔,使冷却水系统的压力升高,压力表指针和膨胀水柜水位均升高;当气缸排气后压力低于冷却水压力,冷却水自裂缝进入气缸大量漏泄,冷却水压力急剧降低,压力表指针和膨胀水柜水位又迅速降低。此外,还可从冷却水温升高,淡水消耗量增加,扫气箱有水流出,膨胀水柜的透气管有气泡冒出和冷却水中有油星等现象进一步判断。至于燃烧室中哪个零件裂穿则需要进一步检查。 2)启动前进行转车和冲车时,轮机员应打开示功阀观察有无水气或水珠喷出。如有水气或水珠喷出表明燃烧室零件有穿透性裂纹或喷油器冷却水漏泄,应进一步检查和处理,否则缸内积水较多直接启动就会造成水击事故。 3)曲柄箱(或循环油柜)中滑油量不正常增多或滑油中水分明显增加,或滑油迅速乳化变质均表明由于燃烧室部件有穿透性裂纹使冷却水大量漏入。 4)吊缸检修时,轮机员应认真仔细观察各个零件,如发现活塞、气缸套和气缸盖表面有锈痕,或活塞顶部积水等,说明燃烧室零件有穿透性裂纹[8]。 4 其他方法 在检修中,还可用荧光法、磁力探伤法、超声波探伤法、射线探伤法等多种方法来检查裂纹。此处不再一一叙述。 5 气缸盖裂纹的应急修理 如果气缸盖裂纹程度较为严重,比如当气缸盖的裂纹是裂穿性的,或者裂纹产生在关键部位,或者裂纹程度较为严重,这些情况无疑都必须更换气缸盖;但当裂纹不严重或为了应急或延长使用,可根据不同的场合选择采用合适的方法进行修理。 1 无机粘结剂修补法 这是一种最方便的方法,由于无机粘结剂能够长期在500度高温下工作,故可用于修补气缸盖底面裂纹。但是由于次温度限制,所以建议在温度处的裂纹采用有机粘结剂修补。 2 金属扣合法 此法的特点是能保证强度又有很好的密封性。对于缸盖底面裂纹的修理较其他方法可靠。为了增加密封性还可在裂纹处先涂一些无机粘合剂(如磷酸—氧化铜粘合剂)或者有机粘合剂,这样效果更好[3]。 3 镶套修理法 主要用于气缸盖进、排气阀孔或喷油器孔内的列修理。通常采用此修理后气缸套可以使用两年以上。衬套的材料一般采用不锈钢或青铜,衬套端部与阀孔底部加紫铜垫以密封。 4 焊补法 当裂纹较短时,在铲去裂纹后进行焊补。 焊补之前气缸盖应预热,焊前现在裂纹两端各钻一止裂孔,并沿裂纹开“U”型坡口,坡口底端应成圆弧形。对于铸铁气缸盖,焊条可用镍基铸铁焊条。每次焊接长度应不超过30~40mm,并趁红热状态用小锤轻轻敲击整个焊道,以防止热裂的产生。锤击后立即用氧—乙炔火焰对准焊缝加热回火,回火温度以焊缝表面呈暗红色即可。 此方法对于焊补工艺要求严格,尤其是铸铁缸盖焊接部位更应特别小心,如焊前的预热、焊后的退火处理及焊条的选择等。因为稍有不当就会在短期使用后因热应力而再次产生裂纹。 5 覆板修理法 此修理法仅适用于气缸盖外表面的修理,可以收到较好的效果。具体现在裂纹两端钻止裂孔,然后将钢板覆盖在裂纹部位上,再用螺钉固紧在气缸盖上。 气缸盖裂纹修理后,应对冷却水腔进行0.7MPa的水压试验,以检验修理质量。裂纹微小时采用锉刀、油石或风沙轮等工具打磨裂纹处予以消除,经无损探伤或水压试验检验合格后继续使用。否则,继续打磨、检验。若裂纹深达壁厚的3%以上时,停止打磨改用其他方法修理或报废换新[10]。 6 预防气缸盖产生裂纹的措施 为了保证柴油机的正常运转,作为柴油机的重要部件,预防其产生裂纹 更为重要,本文总结了以下几条措施。 1 改善气缸盖材质 通过改善材质来减少气缸盖裂纹的产生是一个颇为有效的措施,如缸径为400mm以下的气缸盖通常以灰铸铁普遍,而缸径大于400mm时,由于灰铸铁经不起大变形的长期考验,因而以改用球墨铸铁为宜。 2 气缸盖设计优化 如今年来许多中速柴油机都采用了双层底气缸盖的结构形式,它的设计观点是把热负荷和机械负荷分开来处理,采用较薄的底板可以提高冷却效果,降低底板温差,即用较薄的底板承受热负荷,采用较厚的顶面板、中间隔板和圆周壁来提高刚度承受机械负荷,这样使得机械应力和热应力各得其所。 再如,为减少燃烧室壁上的热应力,缸盖四周不能箍得太紧,缸盖与缸套的定位凸肩要留有充分的余地,有如缸盖阀门的过桥处常易产生裂纹,可在产生裂纹的部位预先铣去一部分金属,以减轻应力集中程度,从而减少了由于热应力过 大而导致裂纹产生的几率。 3 加强对气缸盖过热部位的冷却 在柴油机投入运行前,彻底清洗冷却水腔,保证水路畅通。控制冷却水的质量,按说明书的规定控制好冷却水的温度、温差和流量。在柴油机缸盖冷却水道内增设挡水板,加快水流速度,且对水流给以必要的引导,使其定向地冲刷排气门和喷油器使这些受热严重的部件得较好的冷却。避免长时间超负荷运转,防止过热。当采用外源驱动冷却水泵时,柴油机停车后不应过早停止冷却水循环,以避免产生冷却水“过后沸腾”现象。 4 轮机人员的操作管理科学化。 若对柴油机操作管理不当,同样会导致气缸盖产生裂纹。例如,柴油机冷车启动或启动后加速太快都容易产生裂纹。更甚者,轮机人员在没有充分暖缸的情况下增加负荷,急剧调节冷却水量,造成气缸盖“激碎”现象。这是由于受热部件和冷却液的温度升高都需要有一个过程,如果加速过快,燃烧室部件就会因内外壁温差过大而产生过大的热应力,长此下去,就会产生裂纹,因此,轮机人员启动主机前必须充分暖机,启动后不可加速太快,待油温和水温升高后,方可加至全速,同时还要及时清除冷却水腔中的水垢和铁锈[

Gas cylinder head as diesel engine of fixed parts, is diesel engine combustion chamber of component. ship with diesel engine cylinder cover of structure type type range, random type different and different. in cylinder cover Shang usually layout row valve, and injector, and as shown in the Gong valve, and started valve, and safety valve and into exhaust of driven body,, cylinder cover of within cavity to layout corresponding of stream road, and duct, and and the cooling water cavity,. Therefore, common features of various types of cylinder head is a complex structure, more duct, wall thickness is uneven.

Cylinder head of diesel engine is not only complex, and the conditions of work, force is also very complex and harsh. Cylinder cover of end of surface directly and high temperature high pressure gas contact, not only was high temperature high pressure gas of corrosion and scour, and cycle to bear higher of machinery load and hot load; end of surface in gas of outbreak pressure role Xia produced is large of machinery stress, wall thick and temperature of does not uniform led to higher of hot stress; bolt of pre-tight force make cylinder head bear with pressure stress, and and gas pressure common role make cylinder head was bent role, in section changes Department will produced stress concentrated,. In addition, the corrosion of the cooling water Chamber was subjected to water.

Precisely because of such adverse working conditions of cylinder, cylinder head are easily damaged. Usually corrupted form: its underside and cooling cavity easy to crack, underside and the valve guide bushes also easy to wear, cooling water is corrosive.

This article mainly for marine diesel engine cylinder head most frequently appears to be corrupted--crack, detail, analysing their causes for crack repairs, as well as precautionary measures.

One. Crack of cylinder parts

Marine diesel cylinder head cracks occur mainly at the end of cylinder surface areas of stress concentration, such as a hole or holes with the holes of the round corners, sections such as change of cooling water jacket. Stochastic cracks of concrete parts, cylinder head structure and vary according to the material.

Four-stroke marine diesel engine and fuel injector hole in exhaust valve hole and prone to cracking on the seat surface. When a crack in the bottom surface, mostly radial crack; when the crack is external, cracks are mostly from the Central injector hole expansion to the vent holes, this was due to stress concentration due to small holes (as shown in Figure 1).

Sool tho RD and RND-type diesel engine cylinder cover, cracks occur mostly small cylinder heads on the underside of the central hole, activated valve, safety valve of injector hole holes around the corner, along the radial extension (as shown in Figure 2) [1].

MAN diesel engine cylinder head is composed of two parts, the lower part is made of heat resistant alloys of cast iron, mainly under thermal load; upper part made of grey cast iron, primarily to bear external mechanical load, due to the lower part of the cylinder head cooling cavity layout of the circular cooling water line, so crack

2 reasons for cracks in cylinder

Cylinder head cracking was more common faults of cylinder. Cylinder head cracking due to thermal stress and mechanical stress a recurring role. Alternating thermal stress and under the effect of mechanical stress, fatigue cracks, resulting in cracks in cylinder. Specific analysis of cylinder head cracks the following main reasons.

1 structural design reasons

Around the hole of the bottom surface of cylinder valve is often cracking, mainly because it has a larger surface area, therefore, larger heat expansion and contraction when the cooling rate. For example, the diesel engine work for some time after stopping, cylinder head temperature distribution changes are severe, heat through the cooling and intake and exhaust channels quickly disseminated so prone to cracking at the valve hole.

Furthermore, as force unreasonable, excessive rounded structure or too small will cause excessive mechanical stress, resulting in cracks.

2 reasons for materials and workmanship

Improper cylinder head material selection, quality does not meet the requirements, casting without elimination of casting stress well, resulting in internal defective parts, so that when the cylinder head work is prone to cracking.

3 assembling quality reasons

Cylinder head bolts do not cross tighten as required, or in the event of cylinder flat leak tighten the nut to resolve, caused arising from the uneven force crack of cylinder. Fuel injector is not installed properly, will cause cylinder end of local deformation, increases the injector hole premises subject to tensile stress, making it prone to cracking.

4 operational and administrative reasons

Diesel engine under overload conditions, long running or in cases not fully heated cylinder suddenly increasing load, to make cylinder head sharply from cold to hot, or a sharp cooling in high temperature crack.

Diesel engine cold starts or accelerating too fast after starting, underside and excessive temperature difference of cooling surface of cylinder, heat stress increases. It should be after warm start, starts oil, water temperatures must be accelerated; frequent starting, stopping, and overstretched will enable increased mechanical stress and thermal stress; inadequate cooling and lubrication or break, could also result in part from overheating.

5 causes of poor maintenance

Do not tighten bolts as required when installing the cylinder head, bolt force does not, make additional stress in cylinder heads are too large; long-term use, is not clean cooling water road, water cavity scale, affecting the thermal, thermal stress caused by too large, resulting in cracks.

Fatigue crack propagation in 3 cylinder

1 thermal fatigue crack

The baseboard heating surface "nose area" thermal fatigue crack generated is cylinder four-stroke diesel engines of the more common forms of damage. Thermal fatigue due to the heated surface temperature creep occurs beyond the limits and use of materials, causing plastic deformation. When the cylinder head in alternating hot and cold case work, was hampered by shrinkage deformation of heated surface, resulting in residual tensile stresses. Heated surface temperature exceeds the limit, the more long running time, residual tensile stresses, the larger, eventually suffer fatigue from repeated alternating stress cracks. Serious cracks after a hot and cold cycles occur when [5].

2 mechanical fatigue crack

Gas cylinder head backplane in cylinder within gas pressure role Xia occurs cyclical bent deformation, its maximum stretch stress occurs Yu backplane of inside surface, valve hole Tsim corner Department stress concentrated serious, again overlay Shang hot stress (backplane inside surface by heated stress also for stretch stress) of role, so machinery fatigue crack to this Tsim corner for starting point, along valve hole around gradually to heated surface extended and crack wearing.

3 corrosion fatigue crack propagation

Cooling water contains dissolved oxygen ion and will be on electro-chemical corrosion and oxidation of metals, corrosion and oxidation of metal grain boundaries is first to be part of. This will lead to corrosion of the surface became rough and produces stress concentration, fatigue strength of the material declined significantly. Due to the tapered part of the cylinder head and cylinder misfit, as well as the excessive tightening of cylinder head bolts, diesel engine operation, make the seal flange cooling water larger pulse of mechanical stress. Corrosion and large fluctuation under mechanical stress, corrosion fatigue crack propagation occurs starting from the cooling water.

4 cylinder head crack check

Typically, cylinder head cracks has a generation and development process and, therefore, normally careful checks, careful observation, early detection, will be able to avoid engine damage occurs. Cylinder head crack check there are 3 main methods: direct observation method, dye penetration test method, the hydraulic pressure test method.

1 direct observation method

According to cooling water pressure gauge pointer swings and fluctuations of the water level in the expansion tank and there is no gas, oil stains and other relief to determine whether there are cracks in cylinder, you can also check for white smoke exhaust whether to risk by indicator valve or burning undesirable phenomena to determine crack cylinder in which it occurs. Always check the oil in the crankcase oil change if oil rises, marked increase in moisture in oil, you should suspect has cracked.

2 penetrant inspection method

Penetrant inspection penetrants contain red pigment, solvent and penetrating agents and other ingredients. With strong penetration, penetration speed, when the picture clear and eye-catching, good wash, chemical stability and corrosion-free or low-toxicit, y and so on. Photographic developer is often white powder, such as zinc oxide, magnesium oxide, or titanium dioxide and organic solvent composition. Photographic developer has a better suspension, compared with clear contrast penetrant, display defects in clear, easy to identify, non-corrosive and so on.

IB in a dye penetration test operation, brush and spray law. Pressure sprinkler operation in a simple, easy to carry, and wide application. Sprinkler is equipped with a set of internal pressure cleaner, penetrant and Imaging agents. Inspection, using the surface of the cleaning agents to clean the part to be ch, ecked first, then spray a layer of penetrating agent, based on different materials have different penetration time. Such as aluminum and magnesium alloy castings at room temperature about 15 minutes, steel castings, forgings and shall be not less than 30 minutes; steel and welds have to play 60 minutes; non-metallic materials such as plastic, glass, ceramic 5-30 minutes. Penetrant osmotic effects of time on testing sensitivity is very big. Time is short, hard to find small defects, defect does not display; a long, difficult to clean and test efficiency is low. Penetrant on the surface and then spray the cleaning Imaging agent, and finally to display red on a white substrate defects traces.

3 hydraulic test method

For an internal micro-cracks, such as cooling water jacket of tiny cracks, colouring it is difficult to check, usually do the hydraulic pressure test to check it out.

Hydraulic test method is essentially a pressurized parts in a simulated use conditions there are no material defect inspection of a non-destructive test methods. It does not require any advanced equipment, only with the special clamp and pressure of gases or liquids.

Before the hydraulic pressure test, to be checked on a part of the hole, hole, and all blocked, sealed with special fixture parts sealed cavity formation including test site, fully closed after filled with liquid or gas, pressurized as required to provide testing pressure, maintained a certain amount of time, the observations on the outer surface of the part have no drainage or escape of gases to determine parts without cracks.

Test of liquid water or oil, air can also be used, in respect of the requirements may be. Test pressure to parts of working conditions may be. Pressures of test cylinder head of diesel engine cooling water for 0.7MPa for 5 minutes. In addition, navigation based on the following combustion chamber part no penetrating cracks:

1) diesel engines in operation, engineer according to the cylinder or piston cooling water table fluctuations in pressure pointers or expansion tank water level fluctuations determine parts of penetrating cracks. Because Dang gas cylinder head or cylinder sets has penetrating sexual crack Shi, combustion chamber in the of high pressure gas on will along crack entered cooling water cavity, makes cooling water system of pressure rise, pressure table pointer and expansion tank water level are rise; Dang cylinder exhaust Hou pressure below cooling water pressure, cooling water since crack entered cylinder large leak, cooling water pressure sharp reduced, pressure table pointer and expansion tank water level also quickly reduced. In addition, also available from the cooling water temperature rises, increased consumption of fresh water, water outflow scavenging box, vent tube air bubbles out of the expansion tank and cooling water in the soil further judgement. As to which parts through crack in the combustion chambers you will need further checking.

2) interchange and red car prior to commencement, engineer observation indicator valve should be opened for any moisture or water spray. If moisture or water spray out showed that combustion chamber cooling water leak parts of penetrating cracks or fuel injector, should be further examined and processed, otherwise stagnant water more directly in the cylinder start would result in accidents of water hammer.

3) crank case (or cycle oil tank), oil does not increase in the normal or apparent increase in moisture in oil, or oil emulsion deterioration suggest that rapidly cooling water due to combustion chamber components of penetrating cracks a lot of leaking into the.

4) when a top overhaul, engineer should be carefully observed the various parts, such as piston, cylinder and the cylinder head surface rust found trace amounts of, or top of the piston stagnant water, instructions parts of penetrating cracks of combustion chamber [8].

4 other methods

In inspection and repair, also use fluorescent method, magnetic flaw detection, ultrasonic, radiographic law in several ways, such as to check for cracks. Here are no longer described one by one.

5 emergency repair of cylinder head cracks

If the cylinder head cracks in more serious, such as when a cylinder head crack crack is wearing, or cracks in the key parts, more serious or crack, these circumstances undoubtedly cylinder must be replaced; but when the crack is not serious or emergency or extended use, using appropriate methods can be selected according to different occasions for repairs.

1 inorganic Binder for repairing method

This is one of the most convenient method, because inorganic Binder for long-term work in a 500 degree high temperature, it can be used to repair bottom crack in cylinder. But due to the temperature limit, so organic binder is cracked at the temperature recommended patches.

2 metalock

Features of this law is to ensure strength and good sealing. For reliable repair the bottom face of the cylinder head cracking than other methods. In order to increase the seal can also crack at the first coated inorganic binders (such as phosphoric acid-copper oxide adhesive) or organic binders, so better [3].

3 mounting repair law

Mainly for cylinder Gaijin, vent holes or injector hole repair. This repair is usually cylinder sleeves can be used for more than two years after. Materials generally use stainless steel or bronze bushing, bushing tip and bottom plus copper gasket to seal the valve hole.

4 welding method

When you crack a relatively short, spade came to crack in welding.

Welding cylinder should warm up before, now before the welding crack crack drilled a hole at each end and along the cracked open "u" Groove, Groove bottom should be curved. Cast iron cylinder head and electrodes available nickel-base cast iron electrode. Each time the length should not exceed 30~40mm, and taking advantage of glowing red with a small hammer gently tap the entire welding road, to prevent hot cracking formation. Immediately after hammering with oxygen-acetylene flame at the weld heating tempering, tempering temperature weld surface is dark red.

This method for welding technology requires strict, particularly cast iron cylinder head welded joints with extreme caution, such as preheating before welding, annealing after welding and electrode selection, and so on. Because after the somewhat inappropriate in the short term to use crack again due to thermal stress.

5 repair method of review panel

This repair method applies only to the outer surface of the cylinder head repairs, you can receive better results. Concrete crack drill holes at both ends now, and then steel parts covered in cracks, then tighten the screw on the cylinder head.

Cylinder head cracks repaired, should 0.7MPa the cooling water jacket hydraulic pressure test to verify repair quality. Crack file used in the tiny, oil tools such as stone or sand wheel grinding cracks to be eliminated, NDT or continued use after hydraulic pressure test and inspection. Otherwise, continue polishing, testing. If the above 3% of crack depth of wall thickness, stop grinding to switch to other methods to repair or scrap-for-new [10].

6 measures to prevent cracks in cylinder

In order to ensure normal operation of diesel engines, diesel engine as an important part to prevent its cracking

More importantly, this article summarizes several of the following measures.

1 improved cylinder head material

By improving the material to reduce the generation of cracks in cylinder is a fairly effective measures, such as cylinder 400mm cylinder head below the usually gray cast iron is most common

400-100-8969 15088860848

0574-26871589 15267810868

0574-26886646 15706865167

0574-26871569 18658287286

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文(简)

中文(简) Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska