VOLVO工程机械用柴油发动机电子控制技术

VOLVO工程机械用柴油发动机电子控制技术

由于柴油机具备高扭矩、高寿命、低油耗、低排放等特点 ,柴油机成为解决汽车及工程机械能源问题最现实和最可靠的手段。因此柴油机的使用范围越来越广 ,数量越来越多。同时对柴油机的动力性能、经济性能、控制废气排放和噪声污染的要求也越来越高。依靠传统的机械控制喷油系统已无法满足上述要求 ,也难以实现喷油量、喷油压力和喷射正时完全按最佳工况运转的要求。近年来 ,随着计算机技术、传感器技术及信息技术的迅速发展 ,使电子产品的可靠性、成本、体积等各方面都能满足柴油机进行电子控制的要求 ,并且电子控制燃油喷射很容易实现。

1:沃尔沃柴油机电子控制技术的要求

1.1沃尔沃柴油机高的喷射压力

为满足排放法规的要求 ,柴油喷射压力从 10MPa提高到 200MPa。如此高的喷射压力可明显改善柴油和空气的混合质量 ,缩短着火延迟期 ,使燃烧更迅速、更彻底 ,并且控制燃烧温度,从而降低废气排放。

1.2沃尔沃柴油机独立的喷射压力控制

1.3改善沃尔沃柴油机燃油经济性

用户对柴油机的燃油消耗率非常关注。高喷射压力、独立的喷射压力控制、小喷孔、高平均喷油压力等措施都能降低燃油消耗率 ,从而提高了柴油机的燃油使用经济性。

1.4沃尔沃柴油机独立的燃油喷射正时控制

喷射正时直接影响到柴油机活塞上止点前喷入汽缸的油量,决定着汽缸的峰值爆发压力和最高温度。高的汽缸压力和温度可以改善燃油使用经济性 ,但导致 NOX增加。而不依赖于转速和负荷的喷射正时控制能力 ,是在燃油消耗率和排放之间实现最佳平衡的关键措施。

1.5沃尔沃柴油机可变的预喷射控制能力

预喷射可以降低颗粒排放 ,又不增加 NOX排放 ,还可改善柴油机冷启动性能、降低冷态工况下白烟的排放 ,降低噪声 ,改

善低速扭矩。但是预喷射量、预喷射与主喷射之间的时间间隔在不同工况下的要求是不一样的。因此 ,具有可变的预喷射控制能力对柴油机的性能和排放十分有利。

1.6沃尔沃柴油机最小油量的控制能力

供油系统具有高喷射压力的能力与柴油机怠速所需要的小油量控制能力发生矛盾。当供油系统具有预喷射能力后将会使控制小油量的能力进一步降低。由于工程机械用柴油机的工况很复杂 ,怠速工况经常出现 ,而电喷柴油机容易实现最小油量控制。

1.7沃尔沃柴油机快速断油能力

喷射结束时必须快速断油 ,如果不能快速断油 ,在低压力下喷射的柴油就会因燃烧不充分而冒黑烟 ,增加 HC排放。电喷柴油机喷油器上采用的高速电磁开关阀很容易实现快速断油。

1.8降低驱动扭矩冲击载荷

燃油喷射系统在很高的压力下工作 ,既增加了驱动系统所需要的平均扭矩 ,也加大了冲击载荷。燃油喷射系统对驱动系统平稳加载和卸载的能力 ,是一种衡量喷射系统的标准。而电喷柴油机技术中的高压共轨技术则大大降低了驱动扭矩冲击载荷。

2:VOLVO沃尔沃柴油机组成

VOLVO工程机械用柴油发动机电子控制系统组成

传感器、电控单元、执行器。传感器是用来监控发动机上各部件及各系统的运行状况 ,并将数据传输给 ECU。

( 1)增压压力与温度 ;根据检测到进气压力与温度计算进气量为 ECU提供计算喷油量的数据。

( 2)燃油温度 :燃油温度的升高会影响发动机性能 ,温度高会降低柴油黏度 ,增加泄漏量需要加大供油量。

( 3)冷却液温度 :检测发动机温度提供为 ECU喷油正时修正的数据 ,并且为驾驶员提供发动机运行状况。

( 4)冷却液液位 :监测水箱水位变化。

( 5)发动机凸轮轴速度 :为 ECU提供点火正时信号。

( 6)发动机曲轴速度 :也称为发动机转速传感器 ,提供发动机转速信号。

( 7)机油压力 :监测发动机润滑系统运行状况 ,为驾驶员提供发动机信息。

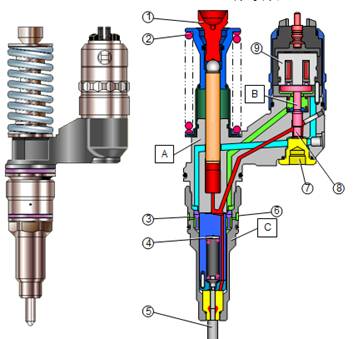

执行器根据电控单元所传输过来的电压信号来控制喷油正时与喷油量 ,在外部环境变化的情况下 ,E-ECU通过一系列传感器采集到的信息 ,经过计算对比分析 ,然后通过对喷油器电磁阀 其工作原理为 :发动机凸轮作用于单体泵挺杆 ,ECU将收集通电时间的长短和早晚来调整喷油量与喷油正时。 VOLVO工程的传感器信号分析处理后发出指令。使高速电磁铁控制阀闭合、机械用柴油发动机的执行器主要是有电磁阀的单体泵。结构和开启 ,在单体泵内形成高压 ,通过喷油器定时、定量将最佳雾化驱动方式。

其工作过程为 :当某缸需要喷油时 ,ECU向电磁阀提供 3.7V的电压 (注:当起动时电压可达 90V左右普通万用表无法测量 ),使电磁阀移动将进油道堵死使内部形成密闭空间 ,此时柱塞在凸轮轴的推动下向上移动 ,建立油压直至达到 220kg将喷油器打开向汽缸内喷射经雾化的燃油 ,工作完成。

另外 ,VOLVO工程机械用电控柴油机还包括对废气再循环阀、预热塞等执行机构进行控制 ,使柴油机运行状态达到最佳。

VOLVO engineering machinery diesel engine electronic control technology

As the characteristics of the diesel engine with high torque, high life expectancy, low fuel consumption, low emissions, the diesel engine automotive and construction machinery, energy issues are the most realistic and the most reliable means. Therefore, the use of diesel engines range more widely, more and more quantity. Diesel power performance, economic performance, control emissions and noise pollution are increasingly high requirements. Rely on traditional mechanical control fuel injection system has been unable to meet the above requirements, it is difficult to achieve the fuel injection quantity, injection pressure and injection timing requirements fully functioning best conditions. In recent years, with the rapid development of computer technology, sensor technology and information technology, reliability, cost, size, and other aspects of the electronic products can meet diesel requirements for electronic control, electronically controlled fuel injection and are easy to implement.

1: Volvo diesel engine electronic control technology requirements

1.1 Volvo diesel engine high injection pressure

To meet emission regulations, diesel fuel injection pressure increased from 10MPa to 200MPa. Such a high injection pressure can be significantly improved the mix quality of the diesel fuel and air, to shorten the ignition delay period, so that combustion is more rapid, more thorough, and controlling the combustion temperature, thereby reducing exhaust emissions.

1.2 Volvo diesel engine independent injection pressure control

1.3 improve Volvo diesel engine fuel economy

The user is very concerned about the fuel consumption of the diesel engine. The high injection pressure, independent of the injection pressure control, small spray holes, high average Injection Pressure and other measures can reduce the fuel consumption rate, thereby improving the economy of the use of diesel fuel.

1.4 Volvo independent diesel engine fuel injection timing control

Injection timing directly affect the amount of oil sprayed into the cylinder of the diesel engine piston top dead point before, determines the peak cylinder pressure and the maximum temperature. The high cylinder pressure and temperature can improve fuel economy, but the NOX increase. Rather than rely on speed and load injection timing control capability is the key measures to achieve the best balance between the rate of fuel consumption and emissions.

The 1.5 Volvo diesel Variable pre-injection control capability

Pre-injection can reduce particulate emissions, without increasing NOX emissions, but also to improve the diesel engine cold start performance, reduce cold conditions white smoke emissions, reduce noise, change

Good low-speed torque. However, the interval between the pre-injection amount, the pre-injection and main injection is not the same in different conditions requirements. Therefore, having a variable pre-injection control capability of the diesel engine performance and emissions are very favorable.

1.6 Volvo diesel engine control capability of the minimum amount of oil

The small amount of oil needed by the fuel supply system with a high injection pressure diesel engine idling control capabilities in contradiction. Further reduce the ability to make the control of a small amount of oil when the oil supply system will have the ability to pre-injection. Idling condition is often very complex construction machinery diesel engine conditions, EFI diesel engine is easy to achieve a minimum fuel control.

1.7 Volvo diesel engine is quick off the oil capacity

Injection end must be fast off oil, and can not quickly off the oil, is injected at a low pressure of the diesel will be due to inadequate combustion smoky, increase in HC emissions. EFI diesel injector using high-speed solenoid switch valve is very easy to implement quick off the oil.

1.8 lower drive torque impact load

The fuel injection system working in a high pressure, both to increase the average torque of the drive system, and also to increase the impact load. Fuel injection system for smooth drive system's ability to load and unload, is a measure of the standard of the injection system. EFI diesel technology in high-pressure common rail technology greatly reduces the impact load of the drive torque.

2: VOLVO Volvo diesel engine composition

VOLVO engineering machinery diesel engine electronic control system components

Sensors, electronic control units, actuators. The sensor is used to monitor the operating conditions of the engine components and systems, and data transmission to the ECU.

(1) The supercharging pressure and temperature; intake air amount calculated according to the detected intake air pressure and temperature, the ECU provides the data of the calculated fuel injection quantity.

(2) Fuel temperature: the fuel temperature rise will affect the engine performance, the high temperature will reduce the viscosity of diesel to increase the amount of leakage need to increase the amount of oil.

(3) The coolant temperature: detection engine temperature ECU fuel injection timing correction of data, and provide the driver with the engine operating conditions.

(4) The coolant level: monitoring the tank water level changes.

(5) Engine the camshaft speed: for the ECU to provide an ignition timing signal.

(6) the engine crankshaft speed: also referred to as the engine speed sensor, the engine speed signal.

(7) Oil pressure: monitoring engine lubrication system operating conditions, for the driver to provide engine information.

The actuator according to the transmission over the voltage signal by the electronic control unit to control injector timing and fuel injection quantity in the case of the external environment changes, E-ECU collected by a series of sensors to the information, after calculation of comparative analysis, and then through injector solenoid valve works: the engine cam acting on single pump tappet ECU will collect the energized length of time, and sooner or later to adjust the fuel injection quantity and injection timing. VOLVO engineering sensor signal analysis and processing to give instructions. High-speed solenoid control valve is closed, the machinery diesel engine actuator solenoid valve single pump. Structure and open, in a high-pressure unit pump, injector timing, the best atomization driven quantitative way.

The course of their work: when a cylinder needs fuel injection ECU to the solenoid valve 3.7V voltage (Note: When starting voltage up to 90V so ordinary multimeter can not measure), the solenoid valve moving Inlet Road blocked so formed inside the confined space, the plunger moves upward in the camshaft driven the establishment of hydraulic until it reaches 220kg open the injector jet by the atomization of fuel into the cylinder, the work is completed.

VOLVO Construction Machinery Diesel Engine and also includes exhaust gas recirculation valves, glow plugs and other implementing agencies to control the engine running state to achieve the best.

400-100-8969 15088860848

0574-26871589 15267810868

0574-26886646 15706865167

0574-26871569 18658287286

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文(简)

中文(简) Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska