威尔信柴油发电机控制屏、威尔信柴油发电机控制屏有哪些型号与功能?

威尔信柴油发电机控制屏、威尔信柴油发电机控制屏有哪些型号与功能?

㈠控制屏

1001控制屏:⑴仪表:电压表、电流表、频率/转速表、运行时间表、冷却水温表、润滑油压力表、电池电压表

⑵有报警灯的故障停机保护( 高水温、低油压)

⑶控制:开关停机运行/预热/启动、急停按钮、告警测试

2001系列:允许通过遥控信号,自动控制发电机组,因而适用TI系列自动负载切换屏组成市电/发电机组全自动切换系统。

2001控制屏⑴ 仪表:电压表、电流表、频率/转速表、运行时间表、冷却水温表、润滑油压力表、电池电压表。

⑵控制:开关停机运行/预热/启动、急停按钮、告警测试

⑶故障停机保护: 启动失败、高水温、低油压、超速/紧急停机

⑷控制屏遥控信号/触点:遥控急停连接线端、故障警报信号干触点

Access4000控制屏:提供开放的通讯协议具有远程监控,能提供多种操作和保护功能的自启动系统。

Access4000:

⑴ 全数字具有4行超宽的LCD显示发电机组相关工作数据。

⑵ 各种故障报警及停机功能

⑶ 开放通讯接口(R422或R485)

⑷ 失电数据自动存储

⑸ 故障历史数据

⑹ 分级保护控制密码

6200系列控制屏:具有自动并机功能的自启动数码式 控制屏,配合市电失压检测模块(AMF)实现全自动的并车。能做到自动分配有功功率和无功功率,即使机组型号不同,自动负载分配程序也同样能够根据机组的输出能力自动按比例分配负载。

6200控制屏:

⑴ 全数字2×4行LCD显示发电机组相关工作数据

⑵ 各种故障报警及停机功能

⑶ 开放通讯接口(R422或R485)

⑷ 相关系统控制

⑸ 相关操作控制

4、威尔信机组其它功能介绍

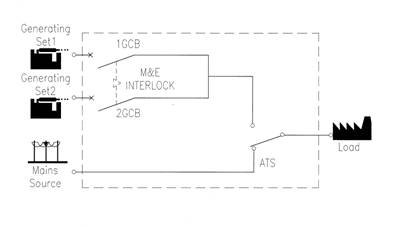

威尔信机组配置2001控制屏及TI/TX的ATS双机备用自动系统(-)

4、威尔信机组其它功能介绍

威尔信机组并机系统功能(二)

1.手动和自动控制单台机组的启停及输出空气开关;

2.LCD宽屏液晶参数显示:油压、水温、电池电压、运行时间等油机参数,三相相电压、线电压、线电流、频率、功率因数、有功功率、无功功率、电度等电参数,并联汇流母线电压、母线与发电机电压、频率、相位差等同步参数;

3.发电机组低油压、高水温、超速、超频、速度信号丢失、起动失败、过流、电压过高或过低、逆功率保护停机;

4.发电机组充电失败、水温高、油压低、电池电压低、传感器故障报警;

5.类似黑匣子的历史事件记录;

6.参数设置授权控制;

7.方便功能扩展。

威尔信机组并机系统功能(三)

1.自动并车,自动按设定的比例实现有功和无功负载的无差分配,自动根据负载波动投入和撤出机组,即当负荷较轻时会自动退出部分机组,当负荷较重时会自动投入部分机组 ;

2.实现多台备用时不停电负载转移;

3.启动负载储备及运行负载储备的设定功能。当负荷在任意点反复波动时都不会造成机组 频繁投切,可保证在负载变动时提供稳定的电力;

4.启动优先顺序可编程设定;

5.机组之间通过CAN工业控制器高速总线进行通讯;

6.具有可编程输入/输出口;

7.易于实现单台手动机组扩容为多台监控并机;

8.根据需要方便扩展并机单元,最多可达8台。

9.通过精确设置参数、优化负载管理来达到可靠和经济运行的目的。

Will believe it diesel generator control panel, will what type diesel generator control panel and function?

Obtaining the control panel

1001 control panel: (1) meter, voltmeter, ammeter, frequency/tachometer, operation schedule, cooling water thermometer, lubricating oil pressure gauge, battery voltmeter

2 have alarm lamp fault shutdown protection (high temperature, low oil pressure)

(3) control: switch stop run/preheating/start, stop button, the alarm test

2001 series: allows remote control signal, automatic generating set control, thus applicable TI series automatic load switch panel of mains/generator automatic switching system.

2001 control panel (1) meter, voltmeter, ammeter, frequency/tachometer, operation schedule, cooling water thermometer, lubricating oil pressure gauge, battery voltmeter.

2: control switch stop run/preheating/start, stop button, the alarm test

(3) downtime protection: failed to start, high temperature, low oil pressure, speed/emergency stop

(4) control panel/remote control signal contact: remote stop cable end, fault alarm and dry contact

Access4000 control panel: open communication protocols with remote monitoring, and can provide a wide range of operation and protection function since the launch of the system.

Access4000:

(1) full digital line with 4 super wide LCD display generator set work related data.

2 all kinds of fault alarm and stop function

(3) open communication interface (R422 or R485)

(4) loss of electricity data storage automatically

The historical data [5]

[6] grading control password protection

Series 6200, control panel, with functions of automatic weaver since the launch of the digital control panel, with mains pressure loss (AMF) to realize automatic detection module and a car. Can do automatic distribution of active power and reactive power, even if the unit model, automatic load distribution program also can also according to the output of the unit capacity proportional distribution load automatically.

6200 control panel:

(1) full digital 2 x 4 line LCD display generator set work related data

2 all kinds of fault alarm and stop function

(3) open communication interface (R422 or R485)

(4) related to the control system

5] related operational control

Unit 4, will believe other functions is introduced

Will believe the unit configuration control panel and TI/TX 2001 ATS double machine automatic backup system (-)

Unit 4, will believe other functions is introduced

Will letter weaver system function (2)

1. Manual and automatic control of a single unit start-stop and output air switch;

2. LCD widescreen LCD parameters display oil pressure, water temperature, oil machine parameters, such as battery voltage, running time, three phase voltage and line voltage and line current, frequency, power factor, active power, reactive power, electricity, electrical parameters, such as parallel bus, busbar and busbar voltage generator voltage, frequency and phase synchronization parameters;

3. The generator set low oil pressure, high water temperature, speed, and overclocking, speed signal loss, start-up failure, over current, voltage too high or too low, reverse power protection downtime;

4. The charging generator failure, high temperature, low oil pressure, low battery voltage, sensor fault alarm;

5. Similar to the black box of historical records;

6. Parameters set authorization control;

7. Convenient function extension.

Will letter weaver system function (3)

1. Automatically and car, automatically set according to the proportion of active and reactive load distribution of no difference, automatically according to load into and withdraw from units, namely when the load is lighter unit automatically exit section, when the load is heavier automatically into part of the unit;

2. Achieve more standby when not transfer power load;

3. Start and running load load reserves set functions. When burden fluctuate repeatedly at any point and don't cause frequent crew cut, can guarantee to provide stable power when load changes;

4. Start the priorities can be set in a programming;

5. High-speed industrial controller through the CAN bus communication between units;

6. A programmable input/output;

7. Easy to implement a single manual unit capacity for monitoring weaver;

Unit 8. According to the need convenient extension weaver, up to eight units.

9. Through precise set parameters, optimization of load management to achieve the goal of reliable and economic operation.

400-100-8969 15088860848

0574-26871589 15267810868

0574-26886646 15706865167

0574-26871569 18658287286

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文(简)

中文(简) Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska