珀金斯发电机组对机房设计技术规范要求

珀金斯发电机组对机房设计技术规范要求

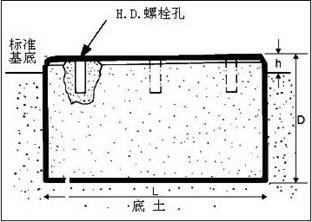

一:机房地基

1.地基类型:

用于固定机组的底座 / 基座的地面 / 地基对于整个发电机机房设计是非常重要的,它必须满足

A 承受机组净重并经受引擎运转时的振动或重压;

B 要足够的坚硬且稳定,这样才不会因发生变形而对引擎和驱动装置的定位造成影响;

C 吸收来自运行组件的振动,且能预防其传递给周围地板及墙壁等。

2.底土选择

A 机房底土必须有足够的承载强度以支撑成套机组加上机组立于其上的混凝土基础重量;若对底土的承载强度不明,应向合格的土木工程师征求意见,以确定混凝土的类型和尺寸;

B 我们提议使用固定的混凝土砌块,并推荐其平面尺寸是在机组的周 边有 300 -450mm 的余量;

C 砌块的表面层高度在 100 -230mm 之间,且形成一个方形底座。

3.混凝土地基

A 砌块深度的计算方法:

D= 混凝土砌块深度 单位: M

W= 发电机总重量 单位: kg

d= 混凝土密度 单位: kg/m ³

(如果此精确值未知, d= 2403.8kg /m ³)

B= 混凝土的宽度 单位: M

L= 混凝土的长度 单位: M

B 混凝土地基

4.多机并机机房中,每台发电机必须拥有自己独立的基座

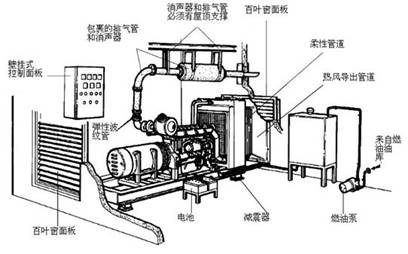

二.机房布置

1.应方便日常护养

2. 机房安装指导

燃油管和接头避免使用塑料和其它不当的材料,因为这些材料可能会腐蚀,或者破损,造成燃料泄漏燃油管路应远离高温排气管排气系统绝热,采用绝热防护罩或绝热材料包裹 注意:干式的排气岐管不能用绝热材料包裹 在机房内安装灭火系统考虑由底壳机油排放措施,在底部准备积污槽检查入口是否足够大,以允许引擎 / 交流发电机移出提供充足的照明和电源插座屋顶起重横梁以便维修保养考虑引擎冷却液排放措施为安全起见,所有旋转轴都要采取相应的防护措施。

3. 典型的机房布置应具有来自散热器的热风用导风管道排至机房外并且避免回流 排气系统从屋顶进行支撑,安装弹性波纹管来隔离引擎和排气系统热风导出管道,燃油管路和电气相对引擎和交流发电机的连接,留有一点的余量日用油箱通过机房外远置安装的油库供应在发动机没有运行期间,启动电池必须使用充电器充满,该充电器可以集成在控制柜内。

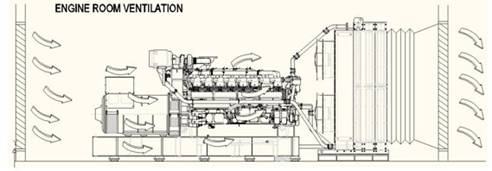

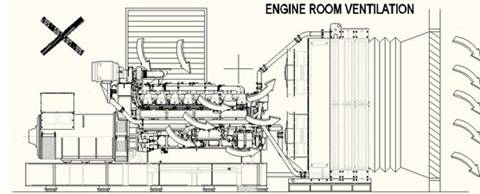

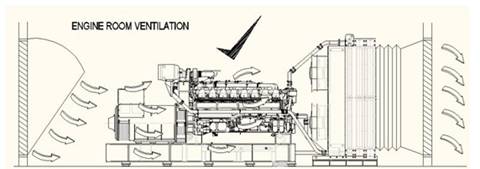

三.机房通风

1.通风

基本原则是将室内热空气排出并在尽可能减小回流的情况下导入外面环境温度下的空气目标是得到尽可能低的的冷空气,使它吹过散热器并排至室外散热器热风必须通过管道引至通风处仅仅将散热器安装在接近墙上的开口处,不是合适的安装。

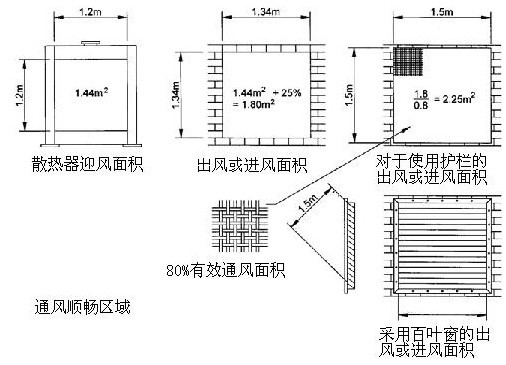

2.出口 / 入口尺寸

排风口应该通风顺畅,并且应该比散热器面积大大约 25%散热器排风管道必须有一段柔性的部分,以隔离振动和运动。对于机组整体安装在减震器上的悬置方式,这一点尤其重要。进风口也应该通风顺畅,并且应该比散热器面积大大约 25%。

Perkins generator set technical specifications for room design

A: room foundation

1 Foundation type:

For fixing the base unit / base floor / foundation for the entire generator room design is very important, it must meet

A unit weight and subjected to withstand vibration or pressure when the engine is running;

B to be sufficiently hard and stable, so that it will not deform and affect the positioning engine and drive unit;

C absorbs vibrations from running components, and can prevent its transmission to the surrounding floor and walls, etc..

2 subsoil choice.

A room subsoil must have sufficient strength to support the complete unit load plus the weight of the unit to stand on the concrete foundation; If the bearing strength of the subsoil is unknown, should consult a qualified civil engineer, to determine the type and size of the concrete;

B We propose the use of a fixed concrete block, and its plane size is recommended in the surrounding units have 300-450mm of headroom;

C block height between the surface layer of 100-230mm, and forming a square base.

3. Concrete foundation

A block depth calculation:

D = depth of concrete masonry units: M

W = the total weight of the generator unit: kg

d = concrete density units: kg / m ³

(If the exact value is unknown, d = 2403.8kg / m ³)

Unit B = width of concrete: M

Unit of length L = concrete: M

B concrete foundation

4. Multi-machine and machine room, and each generator must have its own independent base

Two. Room layout

1 should facilitate daily nursing

2 room installation instructions

Fuel pipe and fittings to avoid improper use of plastics and other materials, because these materials may corrode or damage, resulting in a fuel leak fuel line should stay away from high temperature exhaust pipe exhaust system insulation, the use of insulation or insulation material wrapped shield Note: Dry exhaust manifold extinguishing system can not be installed emission measures considered by the oil pan at the bottom of the tank to check the entrance to prepare the contamination in the engine room is large enough to wrap insulating material to allow the engine / alternator out of the provision of adequate lighting Lifting the roof beams and electrical outlets to consider the engine coolant maintenance emission measures for safety reasons, all axes of rotation should take appropriate protective measures.

3 should have a typical room layout from the evaporator with hot air guide duct and discharged to outside the room to avoid reflux for supporting the exhaust system from the roof, flexible bellows mounted engine and exhaust system to isolate hot export pipeline, fuel line and electrical engines and alternators relative connection, leaving little margin for daily use by tank outside the room away home depot supply installed during engine is not running, start the battery charger must be filled, the charger can be integrated in the control cabinet.

Three. Engine room ventilation

1. Ventilation

The basic principle is to heat the room air is discharged outside the target, and air was introduced at ambient temperature as in the case of reflux is reduced as low as possible to get the cold air to the outdoor side heat sink so that it blows the hot air must pass through the radiator ventilation pipes lead to the radiator just installed close to the wall opening is not suitable installation.

2 outlet / inlet size

Ventilation vents should be smooth and should be more than about 25% of the area is large radiator radiator exhaust pipe there must be a flexible section to isolate vibration and movement. Mounting method for the whole unit is mounted on the shock absorber, which is particularly important. Ventilation inlets should be smooth and should be more than about 25% of the large radiator area.

400-100-8969 15088860848

0574-26871589 15267810868

0574-26886646 15706865167

0574-26871569 18658287286

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文(简)

中文(简) Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska