珀金斯发动机扭振分析(TVA)介绍

珀金斯发动机扭振分析(TVA)介绍

珀金斯发动机扭振分析(TVA)介绍

1、什么是扭振分析

扭振是关于传动系统激励频率对固有频率影响程度的计算,反映了系统是否存在谐振(共振)的危险程度;主要与系统各组成件的转动惯量和扭转刚度 有关,即与设备的结构尺寸有关。

任何旋转系统都会产生扭转振动,特别是单轴承或双轴承交流发电机,研究其全套装置的扭振特性是非常比要的。

2、为什么要扭振分析

扭振分析是装备发动机设备出厂前的必要步骤,也是A&I分析的重要组成部分。

在发动机运行速度的某些范围内,这些振动可足以使曲轴、飞轮螺栓、大齿轮的带齿等断裂。在发生上述危害的任何地方的速度范围内的点,称之为“临界速度”。

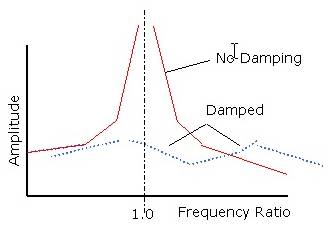

该扭转振动分析的目的是计算出量级和扰动力频率的临界转速点,并确保破坏临界速度超出了引擎运行范围,且非常明显地使其在+10%到-5%的同步速度范围内。有一些临界转速可能在从启动到同步转速的95%范围内,但是这些都可能被视为“安全”,临界转速立刻通过,因为“临界转速”1秒左右立刻通过。

但是,如果该应用需求为“全速”范围,那么所有的临界转速必须控制在安全范围内。

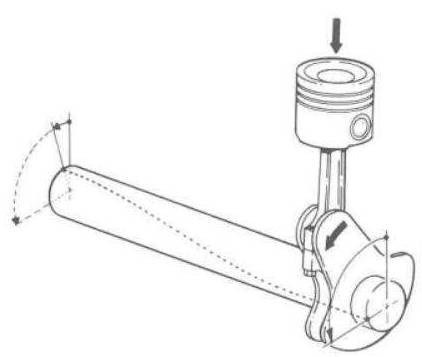

在四冲程循环中,每个汽缸瞬间气压发生着变化,那么任何点上的扭矩也在发生着变化。这将导致曲轴在其均值旋转位置附近出现“摇晃”的情况。

当扭矩组件与轴的自然频率同相时会发生共振;严重情况下,将会导致曲轴断裂

3.如何进行扭振分析

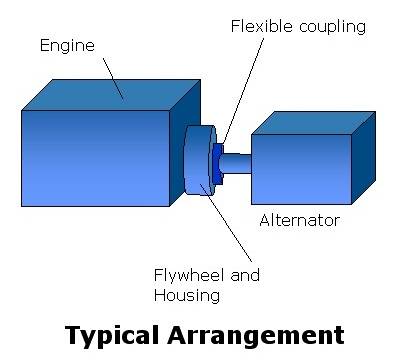

ISO 8528 指定确保扭振兼容性为发电机组制造的责任,珀金斯发动机装备时刻通过以下方式进行扭振分析

<1> 所需资料:曲轴、皮带轮等旋转零部件的惯量及轴的尺寸和刚性;

<2> 可以通过OCD流程进行申请PERKINS发动机的TVA计算,但需收费;

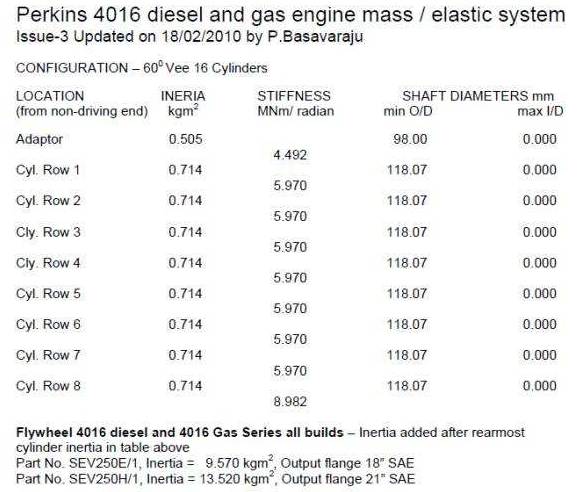

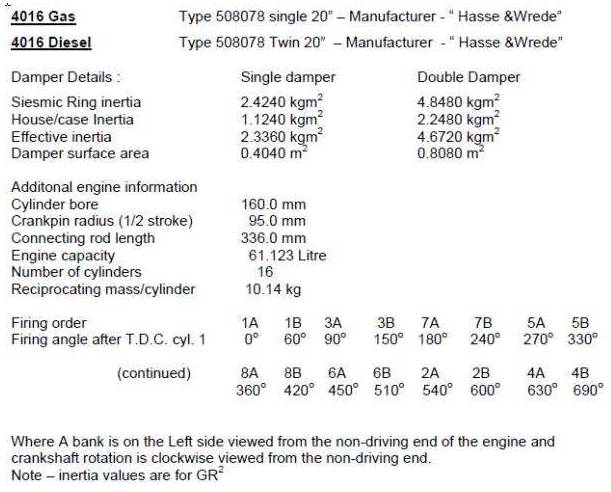

<3> OEM希望自己进行TVA计算,PERKINS可以提供计算所需要的发动机数据;如图

PERKINS 规定:没有通过TVA计算的PERKINS发动机安装是不允许的;否则由安装引发的任何问题和故障PERKINS不承担任何保修。

Perkins engine torsional vibration analysis (TVA) Introduction

Perkins engine torsional vibration analysis (TVA) Introduction

1, What is torsional vibration analysis

Driveline torsional vibration excitation frequency is about the degree of influence on the natural frequency is calculated to reflect the existence of the system resonance (resonance) the degree of risk; primarily composed of members of each of inertia and torsional stiffness of the system concerned, that's about the size of the equipment and structure .

Any rotation system will produce torsional vibration, especially single or double bearing alternator, research torsional vibration characteristics is its full device than want.

2, why should torsional vibration analysis

Torsional Vibration analysis is a necessary step before leaving the factory equipped engine equipment is an important part of A & I analysis.

Within a certain range of engine operating speed, which may be sufficient to make the vibration of the crankshaft, flywheel bolts, toothed gear or the like breaking. Point anywhere within the speed range of the hazard occurrence, called "critical speed."

The purpose of the torsional vibration analysis is to calculate the magnitude of the critical point and the rotation speed of the power frequency interference and ensure destruction of critical engine speed exceeds the operating range, and it is obvious to -5% to +10% of the synchronous speed in the range of . Some may be critical speed within the range from the start to 95% of synchronous speed, but these are likely to be considered "safe", through the critical speed immediately, because the "critical speed" of about 1 second through immediately.

However, if the application needs to "full" range, then all the critical speed must be controlled within a safe range.

In the four-stroke cycle, each cylinder pressure is changing moment, then torque at any point is changing. This would lead to "wobble" in the case of crankshaft rotation around its mean position.

When the natural frequency of the shaft torque component in phase with the resonance occurs; severe cases, will lead to the crankshaft fracture

3 How to torsional vibration analysis

ISO 8528 designated responsibility for ensuring the compatibility of torsional vibration generators manufactured by Perkins Engines equipped moment torsional vibration analysis in the following manner

<1> required information: the size and rigid crankshaft pulley and other rotating parts inertia and axes;

<2> can apply PERKINS engines process TVA calculated by OCD, but for a fee;

<3> OEM TVA wants to be calculated, PERKINS can provide the required computing engine data; Figure

400-100-8969 15088860848

0574-26871589 15267810868

0574-26886646 15706865167

0574-26871569 18658287286

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文(简)

中文(简) Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska