Perkins4016/4012/4008柴油发动机冷却系统/节温器/测试压力测试维修技术参数资料手册

Perkins4016工业柴油发动机冷却系统概述(冷却系统)

在本手册中和在产品上都提供有安全预防措施和警告。如果对这些警告不予注意会给自己或他人造成人身伤亡。

识别危险用“安全警告符号”和“标志文字”,如“危险”、“警告”或“当心”。“警告”标贴如下所示

Perkins4016柴油发动机冷却系统概述

该发动机有一种加压冷却系统。此冷却系统有两个优势。

•压力有助于防止气穴。

•沸腾的风险降低。

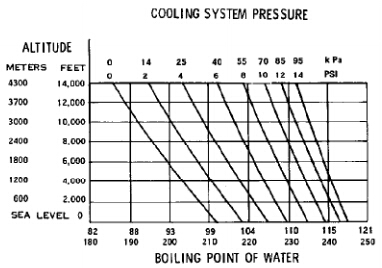

沸点受三种因素影响:压力,海拔和冷却液中的乙二醇浓度。液体沸点随着压力增加而增加。液体沸点随着海拔高度增加而降低。图39显示压力和海拔对水的沸点的影响。

冷却液沸点也取决于冷却液的类型和乙二醇的浓度。乙二醇浓度越大,沸点越高。但是,乙二醇传热效果不及水。因为沸点和传热的效率,乙二醇的浓度很重要。与冷却系统相关的有三个基本故障

•过热

•冷却液损失

•过冷

如果冷却系统没有正确保养,如结垢和沉淀物等固体会降低冷却系统的传热的能力。发动机工作温度会升高。

当发动机超载时,发动机将在拖动状态下运转。当发动机在拖动状态下运转,也即发动机在较低的转速下运转,这样降低了冷却液液流。在高负载下减少冷却液液流将引起过热。泄漏使冷却液缺失。过热的冷却液可通过冷却系统压力安全阀溢出。较低的冷却液液位也会产生过热。过热导致象缸盖裂纹和活塞粘缸现象发生。

缸盖或气缸套裂纹将迫使废气进人冷却系统。额外的压力引起'冷却液丢失、水泵气穴、冷却液循环量少和进一步的过热。

过冷是冷却液旁通水温调节器的结果并直接流人散热器或热交换器。在低环境温度下低负载工作可能引起过冷。过冷由水温调节器保持打开引起的。过冷降低工作效率。过冷使发动机机油快速污染。这样导致曲轴箱形成油泥,气门积炭。加热和冷却循环过快可能导致气缸盖裂纹、密封垫故障、加速磨损和燃油消耗过量。如果怀疑冷却系统有故障,在对系统进行任何测试前,进行目视检查。

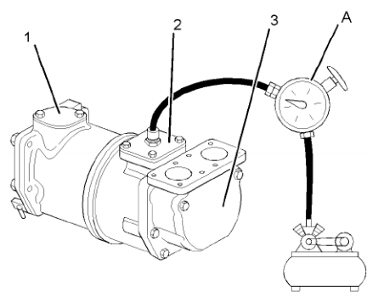

Perkins柴油发动机机油冷却器压力测试

1.制作护板(1)。制作连有空气管接头的护板。

2.用干净的热水加注机油冷却器.使水位在出口法兰范围内。

3.将新接头安装至护板(1)和(3)。将护板(1)和(3)安装至机油冷却器。

4.将压缩空气连接至机油冷却器。使用工具(A)。将压力设置为345 kPa (50 psi)o压力应持续三分钟保持稳定。

目视检查

冷却系统如果不进行定期检查就会引起发动机温度升高。在用测试设备进行测试之前.先对冷却系统进行目视检查。

警告:加压的系统:热的冷却液能造成严重的烫伤。在发动机停机.等待冷却系统部件冷却下来后再打开冷却系统加注口盖。暖慢松开冷却系统加注口盖,以释放掉所有压力。

1.检查冷却系统中的冷却液液位。读取位于散热器(如有配备)上端的两个冷却液液位指示仪指示的液位位置。

2.查看冷却系统有无渗漏。

3.查看芯件散热片是否弯曲或散热器散热片之间有无碎屑(如有配备)。确保流过散热器的空气没有阻塞。

4.检查风扇叶片是否损坏(如有配备)。

5.发动机冷却后,缓慢取下加注口盖。这会使冷却系统内的所有压力释放出来。检查加注口盖和气密封表面。该表面必须清洁,密封必须无损。

6.检查压力安全阀。请联系OEM了解更多信息。

Perkins柴油发动机水温调节器(节温器)一测试

警告:热的冷却液、蒸汽和碱会造成人身伤害。在工作温度下,发动机冷却液是热的而且处在压力下。散热器和所有到加热器的管路或发动机中都有热的冷却液或蒸汽。与它们的任何接触都会造成严重烫伤。只有当发动机停机且散热器盖已经冷却到可以徒手触摸时,再慢慢拆下过滤器盖以释放压力。冷却系统调节器含碱。应避免它与皮肤和眼睛接触。

注:该信息仅适用于安装在发动机上的淡水温度调节器。

1.从发动机上拆下水温调节器。

2.在适当的容器内逐渐加热冶却液。

3.将水温调节器悬挂在冷却液容器内。水温调节器必须浸没在容器中冷却液面以下,但远离容器四周和底部。

4.保持冷却液处于正确温度10分钟。水温调节器开启温度为71.C。

5. 10分钟后,取出水温调节器。确保水温调节器的阀完全开启。如果水温调节器的阀不能在规定温度下开启,更

换水温调节器。更多信息,请参阅《操作和保养手册》,“水温调节器.更换”。

The cooling system of industrial diesel engine Perkins4016 (cooling system)

Important safety instructions

Perkins products operation, maintenance and repair of the most accidents, are caused by not Cui Shou basic safety rules or preventive measures. If you can recognize the various potential risk before the accident, the accident is often avoided. The risk potential, must be warned about the working personnel. Must also be for staff training. To acquire the necessary skills and normal use of tools.

Incorrect operation, small sliding, maintenance or repair the product is dangerous, and can cause personal injury.

You must read and understand the product operation, lubrication, maintenance and repair information, to carry out the work.

In this manual and in the product is provided with safety precautions and warnings. If not pay attention to will cause personal injury to themselves or others to these warnings.

Hazard identification with "safety warning symbols" and "text", such as "dangerous", "warning" or "be careful". "Warning" stickers are shown as follows

The cooling system of Perkins4016 diesel engine

The engine has a compression and cooling system. The cooling system has two advantages.

• pressure helps to prevent cavitation.

• boiling to reduce risk.

Boiling point is affected by three factors: pressure, ethylene glycol concentration elevation and in cooling liquid. The boiling point of a liquid increases with the increase of pressure. The boiling point of a liquid decreases with the increasing altitude. Figure 39 shows the effect of pressure and altitude on the boiling point of water.

The concentration of coolant boiling point also depends on the cooling fluid type and ethylene glycol. Ethylene glycol concentration, the higher boiling point. However, ethylene glycol heat transfer effect than water. Because the boiling and heat transfer efficiency, the concentration of ethylene glycol is very important. Associated with the cooling system has three basic fault

• overheating

• coolant loss

• cold

If the cooling system without proper maintenance, such as the ability to scale and sediment and other solid will reduce the heat transfer of the cooling system. Engine operating temperature will rise.

When the engine is overloaded, the engine will run in the driving condition. When the engine is running in the driving state, namely the engine running at low speed, thus reducing the coolant flow. Under the high load reduced coolant flow will cause overheating. Leakage cause coolant loss. Coolant overheating by cooling system pressure relief valve overflow. Coolant level low will cause overheating. Overheating occurred as a crack in the cylinder head and piston cylinder sticking phenomenon.

Cylinder head or cylinder liner crack will force the exhaust gas into the cooling system. Additional pressure caused by 'loss of coolant, pump cavitation, cooling fluid circulation quantity and further overheating.

Cold is the coolant temperature regulator and bypass the direct flow radiator or heat exchanger. Under low ambient temperature low load operation may cause cold. Cooling by water temperature regulator is kept open by. Too cold to reduce work efficiency. A cold engine oil rapid pollution. This leads to the crankcase to form sludge, valve deposits. The heating and cooling cycle too fast may lead to cylinder head gasket failure, crack, accelerated wear and excessive fuel consumption. If you suspect that the cooling system failure, in any testing of the system, visual inspection.

Perkins diesel engine oil cooler pressure test

1 making protective plate (1). Making even the air pipe plate joint.

2 hot water filling oil cooler clean. The water level in the outlet flange range.

3 new joint installation to guard plate (1) and (3). The protection plate (1) and (3) mounted to the oil cooler.

4 the compressed air is connected to the oil cooler. Use the tool (A). Set the pressure to 345 kPa (50 psi) O pressure should last three minutes remained stable.

Visual inspection

The cooling system without regular inspection will cause the engine temperature. Before the test by the test equipment. To perform a visual inspection of the cooling system.

Warning: the pressurized system: the hot coolant can cause severe burns. In the engine stop. Wait for the cooling system components to cool down after the open cooling system filler cap. Warm slowly loosen cooling system filler cap, to release all pressure.

Coolant level 1 checking the cooling system. Reading is located in the radiator (if equipped) level position at the top of the two coolant level indicator.

2 check the cooling system without leakage.

3 see the core piece of radiating fin is bent or radiator fins are free of debris (if equipped). Ensure that the flow through the radiator air without obstruction.

4 check the fan blade is damaged (if equipped).

The 5 engine cooling, slowly remove the filler flap. This will make all the pressure in the cooling system release. Check the filler cap and sealing surface. The surface must be clean, the seal must be lossless.

6 check the pressure safety valve. Please contact OEM for more information.

Perkins diesel engine water temperature regulator (thermostat) test

Warning: the cooling liquid, steam and alkali heat will cause personal injury. At operating temperature, engine coolant is hot and under pressure. The radiator and all to the heater pipe or the engine is hot coolant or steam. Any contact with them can cause serious burns. Only when the engine is shut down and the radiator cap has cooled to hand can touch, and then slowly remove the oil filter cover to release the pressure. Cooling system conditioner containing alkali. It should avoid contact with skin and eyes.

Note: this information applies only to fresh water temperature is installed in the engine

湖南珀金斯工程机械设备有限公司

整机销售部:0731-84424871 18374999699

售后维修部:0731-84424873 18374999949

配件销售部:0731-84424872

传 真:0731-88835704

地 址:长沙市雨花区汇金路777号

网 址:www.perkins-rx.com400-100-8969 15088860848

0574-26871589 15267810868

0574-26886646 15706865167

0574-26871569 18658287286

English

English Espaol

Espaol Franais

Franais 阿拉伯

阿拉伯 中文(简)

中文(简) Deutsch

Deutsch Italiano

Italiano Português

Português 日本

日本 韩国

韩国 български

български hrvatski

hrvatski esky

esky Dansk

Dansk Nederlands

Nederlands suomi

suomi Ελληνικ

Ελληνικ 印度

印度 norsk

norsk Polski

Polski Roman

Roman русский

русский Svenska

Svenska